A method for preparing ultra-light ceramsite by using heavy organic polluted soil and non-ferrous metal smelting slag

A non-ferrous metal and organic pollution technology, applied in the field of soil remediation, can solve problems such as residues, and achieve the effect of reducing production costs and saving natural resources

Active Publication Date: 2022-05-31

HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD +1

View PDF18 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing preparation of ceramsite with organic polluted soil as raw material mainly uses fly ash and sludge as ingredients, but there are few reports on the preparation of ceramsite with non-ferrous metal smelting slag as ingredients. The ceramsite prepared with organic polluted soil as raw materials can meet the requirements for the use of building light aggregates, and the risk of heavy metals, dioxins and other pollutants released during the process of ceramsite preparation is controllable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

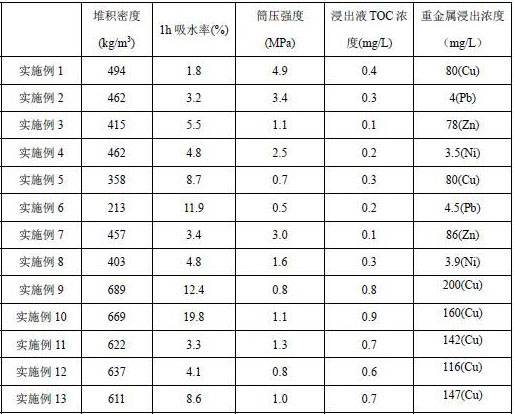

Embodiment 1

[0081] The inorganic composition of the heavy organic polluted soil used in the present embodiment (inorganic substances are all calculated as oxides) and organic compounds.

Embodiment 2

[0089] The inorganic constituents of the heavy organic polluted soil used in this example (inorganic substances are all calculated as oxides) and organic compounds.

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to view more

Abstract

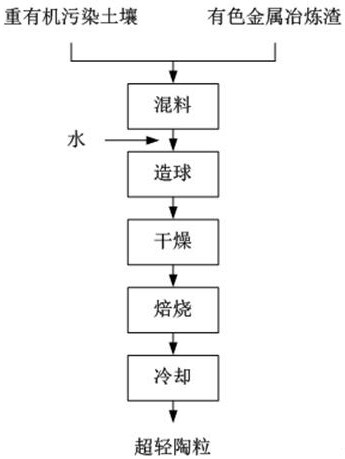

The invention relates to a method for preparing ultra-light ceramsite by using heavy organic polluted soil and non-ferrous metal smelting slag. The preparation method of the ultra-light ceramsite includes the following steps: (1) mixing heavy organic polluted soil and non-ferrous metal smelting slag in proportion to obtain a mixed material; (2) granulating the mixed material in step (1), Roasting to obtain ultra-light ceramsite. The present invention can use heavy organic polluted soil and non-ferrous metal smelting slag as raw materials, through the steps of mixing, granulating, drying, roasting, cooling, etc., and by controlling the ratio of raw and auxiliary materials and roasting process parameters, it can be prepared with low bulk density, Ultra-light ceramsite with low water absorption, organic matter content and heavy metal content in the leach solution can meet the requirements, and realize the harmlessness and resource utilization of the two wastes.

Description

A method for preparing ultra-light ceramsite by using heavy organic polluted soil and non-ferrous metal smelting slag method technical field The invention belongs to the technical field of soil remediation, be specifically related to a kind of utilization of heavy organic polluted soil and non-ferrous metal smelting technology. Method for preparing ultra-light ceramsite by smelting slag. Background technique [0002] With the transformation and upgrading of economic development in recent years, the optimization and adjustment of industrial structure and layout, 3. "Industrial enterprises enter the park and enter the zone", especially the vigorous promotion of supply-side structural reforms, a large number of outdated production capacity have been eliminated, due to one Due to the relocation or closure of some traditional polluting enterprises such as chemical and metallurgy, industrial pollution sites are constantly generated, and there are a large number of polluted s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C04B33/132C04B33/138C04B33/32

CPCC04B33/132C04B33/138C04B33/32C04B2235/6562C04B2235/6567C04B2235/6565C04B2235/77C04B2235/96Y02P40/60

Inventor 陈辉霞佟雪娇王源胡大海黄涛宋庆赟徐红彬张奇

Owner HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap