Manned lifting type vertical shaft measuring device and operation method thereof

A measuring device and lifting technology, which are applied in elevators, transportation and packaging, elevators in buildings, etc., can solve the problems of large limitations of measuring tools, inconvenient comprehensive measurement, and difficult operation, so as to facilitate the promotion and use, improve the Safe to use and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

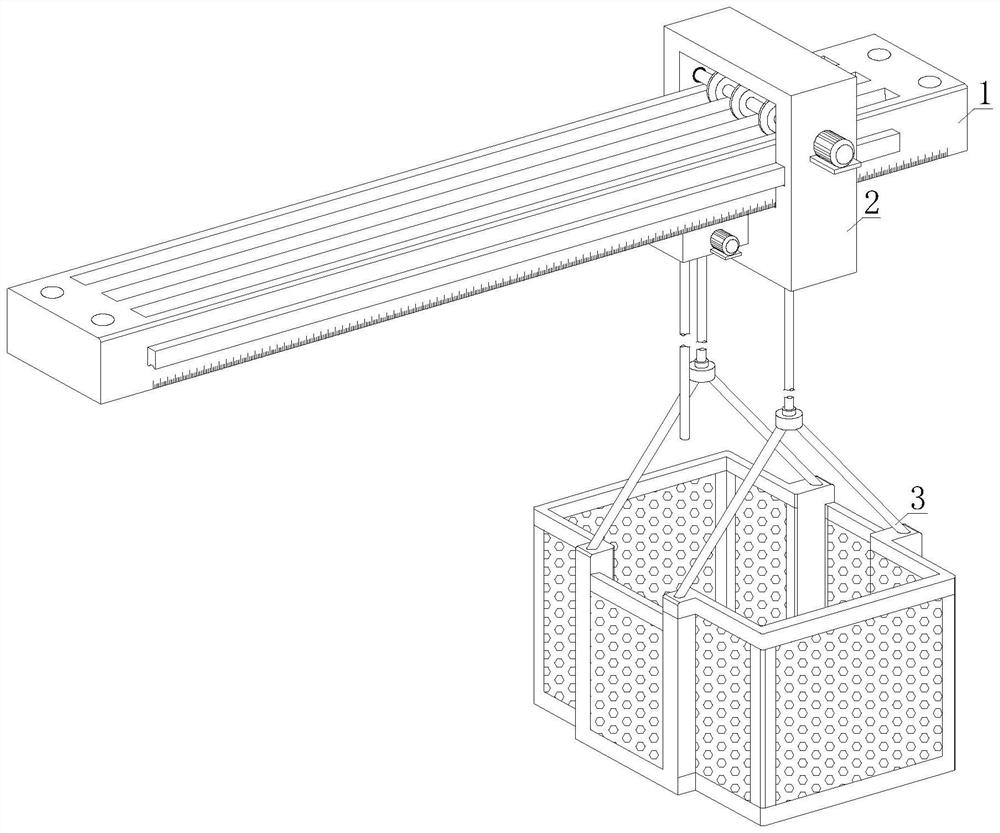

[0039] refer to figure 1, a manned lifting type shaft measuring device, including a support mechanism 1, an adjustment mechanism 2 and a manned measurement mechanism 3, the adjustment mechanism 2 is set on the outside of the support mechanism 1, and the manned measurement mechanism 3 is arranged at the lower end of the adjustment mechanism 2.

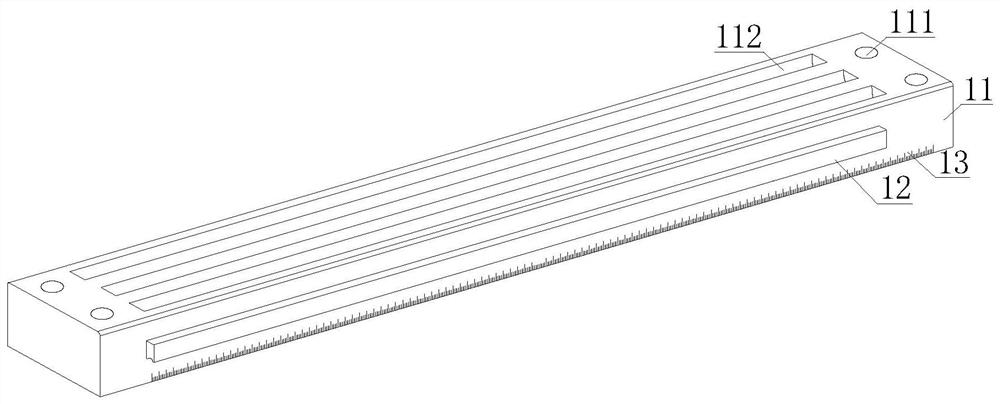

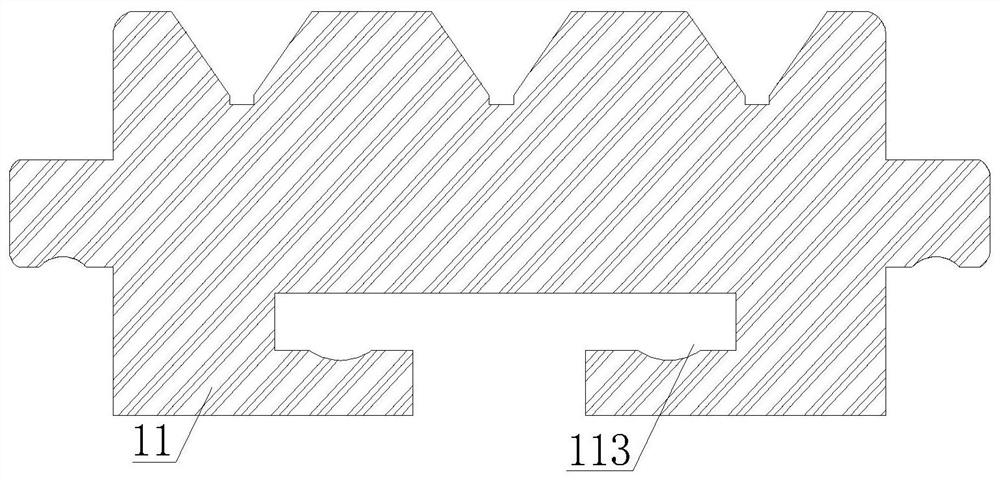

[0040] refer to Figure 2-3 , a manned lifting shaft measuring device, the support mechanism 1 includes a support plate 11, a slider 12 and a scale line 13, the support plate 11 is a member made of a stainless steel material, and the slider 12 is arranged on both sides of the support plate 11 In the middle part of the side, the scale line 13 is located at the lower end of the slider 12 and is arranged on both sides of the support plate 11 . Both ends of the support plate 11 are provided with fixed perforations 111 , the upper end of the support plate 11 is provided with three rolling grooves 112 , and the lower end of the support plate...

Embodiment 2

[0051] refer to figure 1 , a manned lifting type shaft measuring device, including a support mechanism 1, an adjustment mechanism 2 and a manned measurement mechanism 3, the adjustment mechanism 2 is set on the outside of the support mechanism 1, and the manned measurement mechanism 3 is arranged at the lower end of the adjustment mechanism 2.

[0052] refer to Figure 2-3 , a manned lifting shaft measuring device, the support mechanism 1 includes a support plate 11, a slider 12 and a scale line 13, the support plate 11 is a member made of a stainless steel material, and the slider 12 is arranged on both sides of the support plate 11 In the middle part of the side, the scale line 13 is located at the lower end of the slider 12 and is arranged on both sides of the support plate 11 . Both ends of the support plate 11 are provided with fixed perforations 111 , the upper end of the support plate 11 is provided with three rolling grooves 112 , and the lower end of the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com