Full-dry optical fiber ribbon optical cable and manufacturing method thereof

A production method and technology of optical fiber ribbon, applied in the field of optical communication transmission, to achieve high splicing efficiency, low attenuation change rate, and high fiber capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

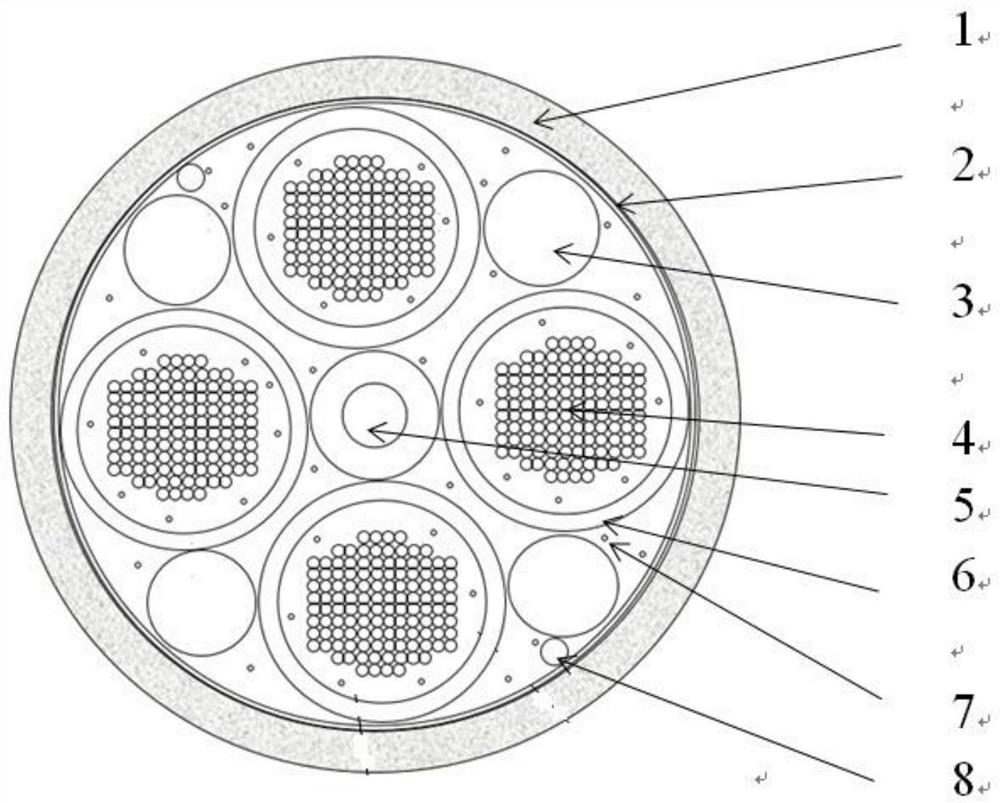

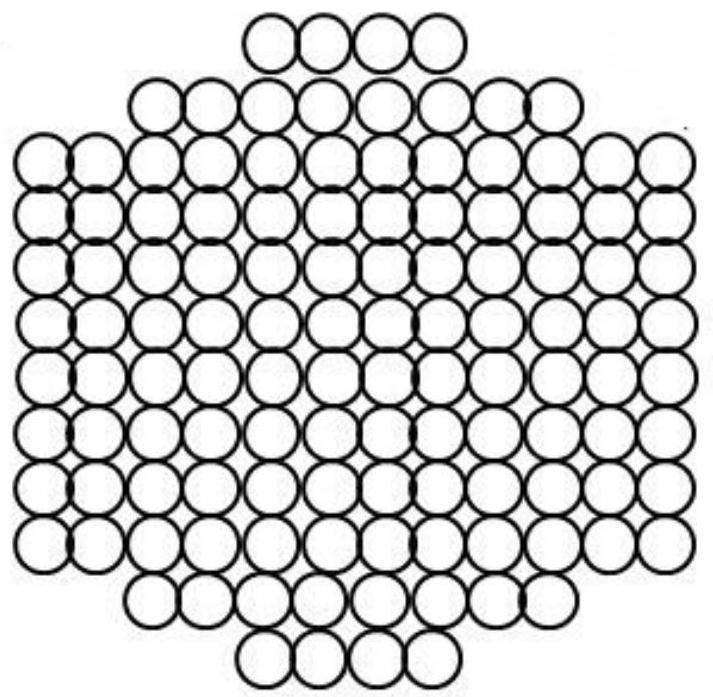

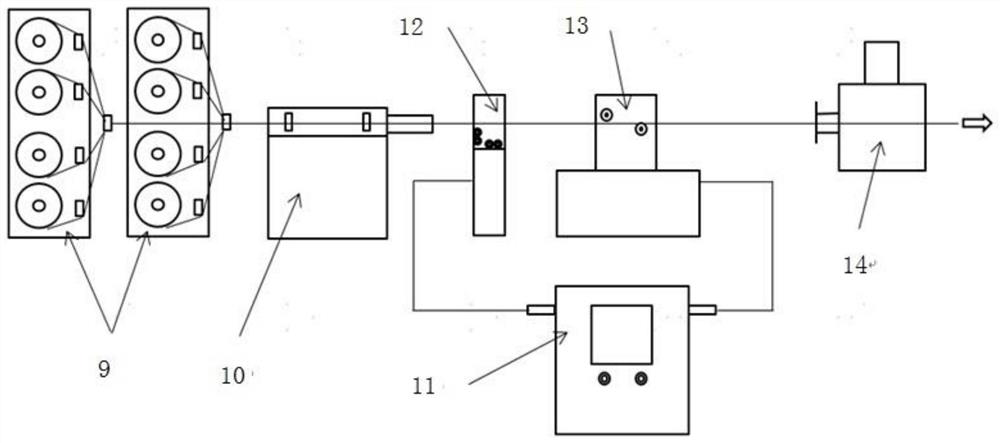

[0023] The structure of an embodiment of the optical cable of the present invention is as follows: figure 1 , 2 As shown, it includes a cable core and an outer sheath 1. The cable core is a layer-stranded cable core, and the layer-stranded cable core includes a central strength member 5 and a sleeve twisted on the periphery of the center strength member. 6. An array-type optical fiber ribbon 4 is set in the sleeve, and the array-type optical fiber ribbon includes a rectangular array formed by 12 vertically stacked 8-core optical fiber ribbons. On the upper and lower sides of the rectangular array (long 2 layers of optical fiber ribbons are stacked on each side, and the number of cores of each layer of optical fiber ribbons is decreasing from the inside to the outside, respectively 8 cores and 4 cores. The connections at the top of the optical fiber rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com