Measurement test system for two-port component between any two points

A technology for testing systems and components, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as difficulty in ensuring the consistency of measurement and test data, increasing the workload of operators, and not having arbitrary and convenient expansion conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

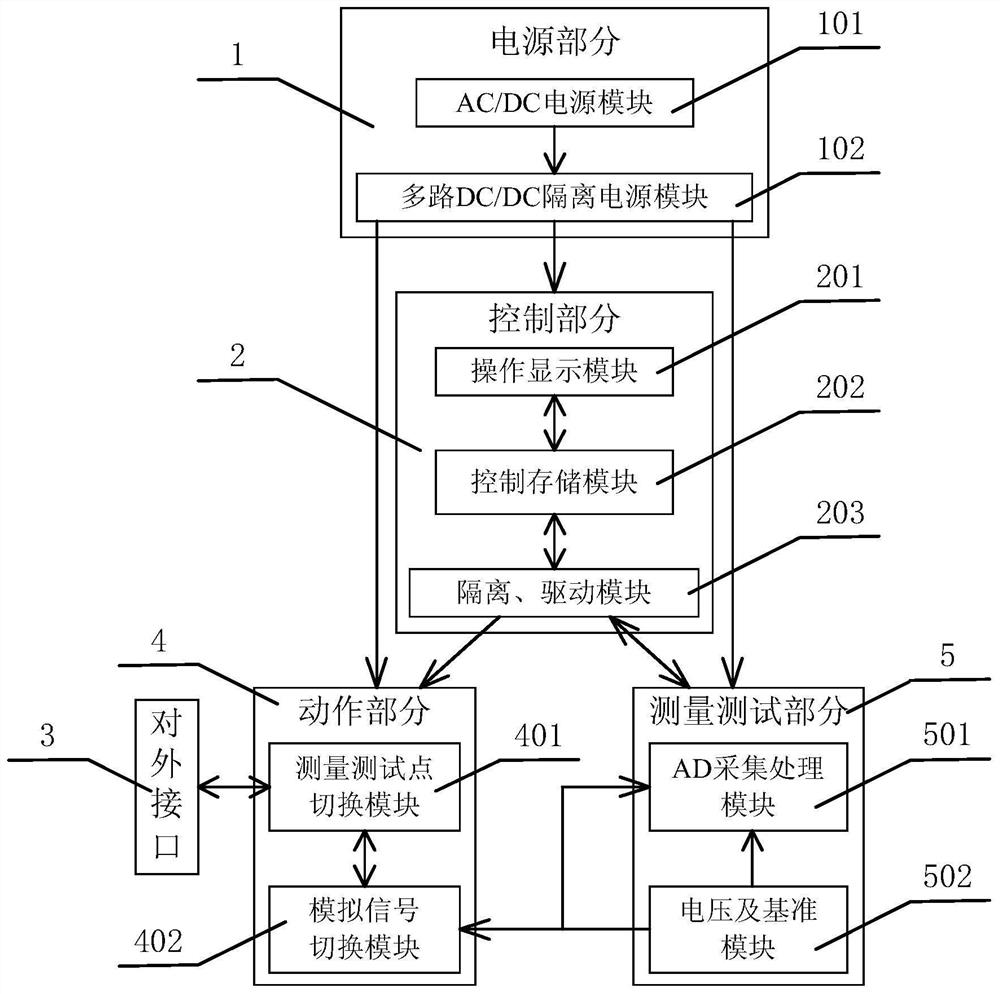

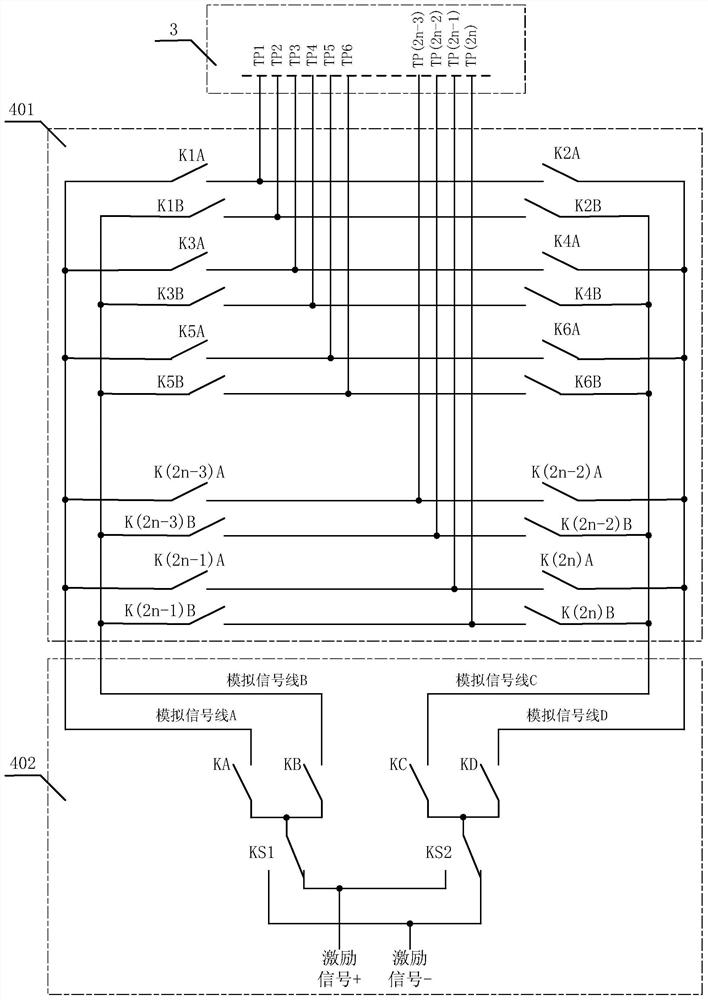

[0074] The present invention is a two-port component measurement and testing system between any two points, including a power supply part, a control part, an action part, a measurement test part and an external interface; the power supply part includes an AC / DC power supply module and a multi-channel DC / DC isolation power supply module; the control part includes the operation display module and the control storage module, as well as the isolation and drive module; the external interface is a related form of connector; the action part includes the measurement test point switching module and the analog signal switching module; the measurement test part includes the AD acquisition and processing module and voltage and reference module; the present invention can arbitrarily expand the scale of the measurement and test point switching modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com