Pipe rotating device

A technology of a coiler and a connecting pipe, which is applied in the field of winding equipment, can solve the problems of affecting the winding work, time-consuming and laborious, and twisted water pipes, and achieves the effects of simple structure, convenient use and smooth water supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

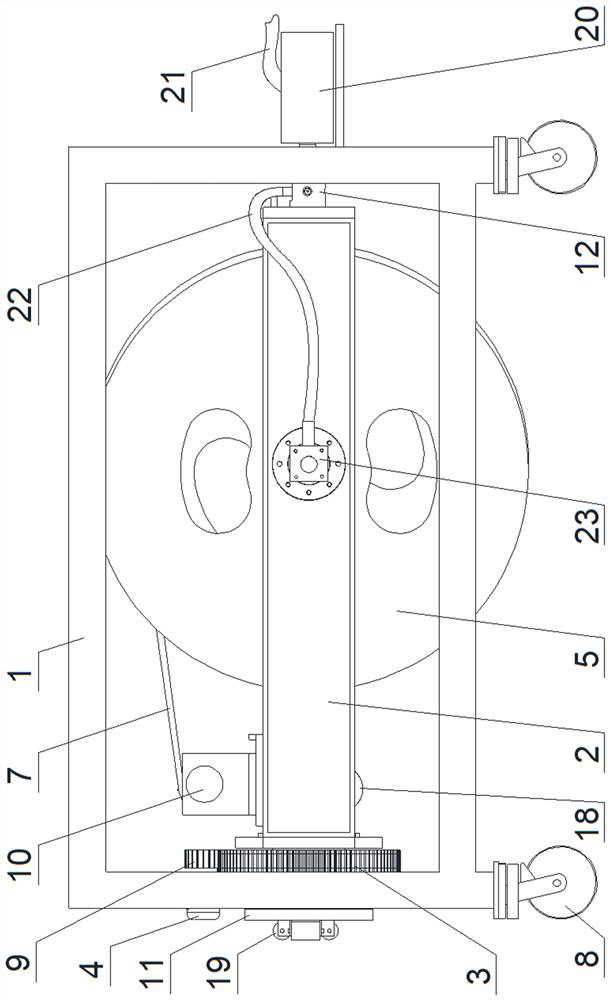

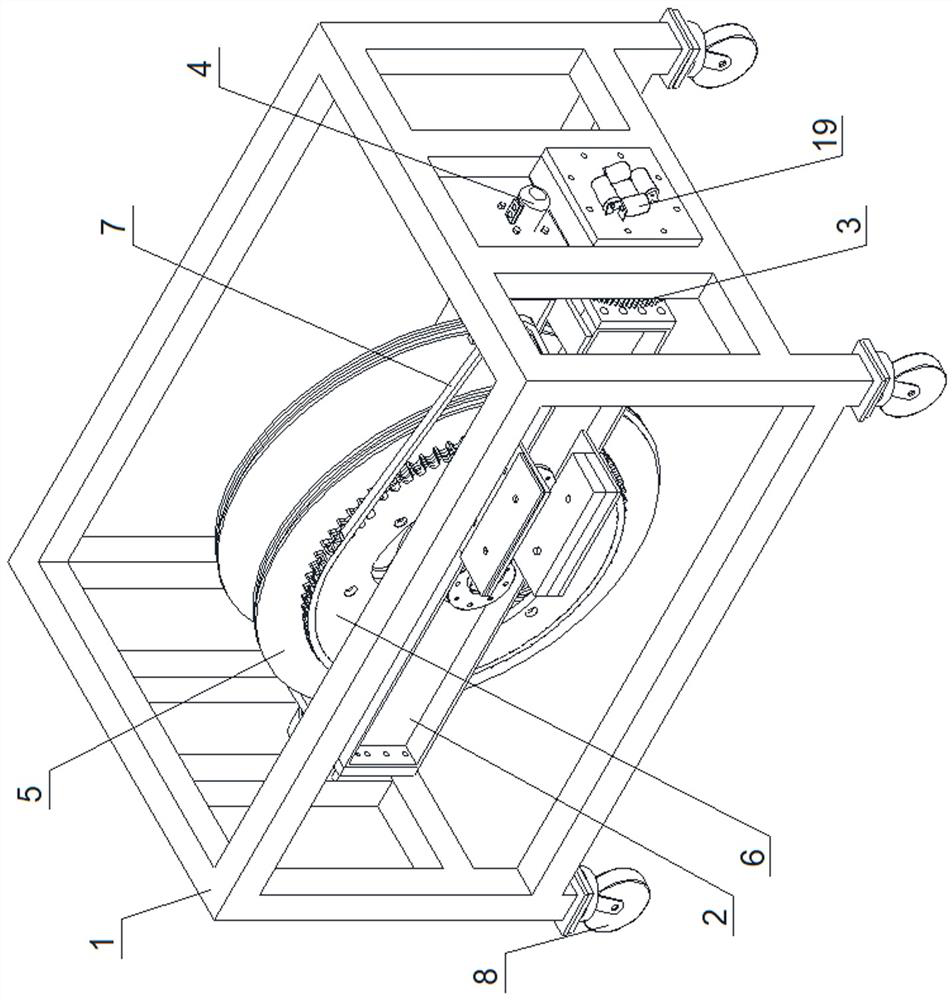

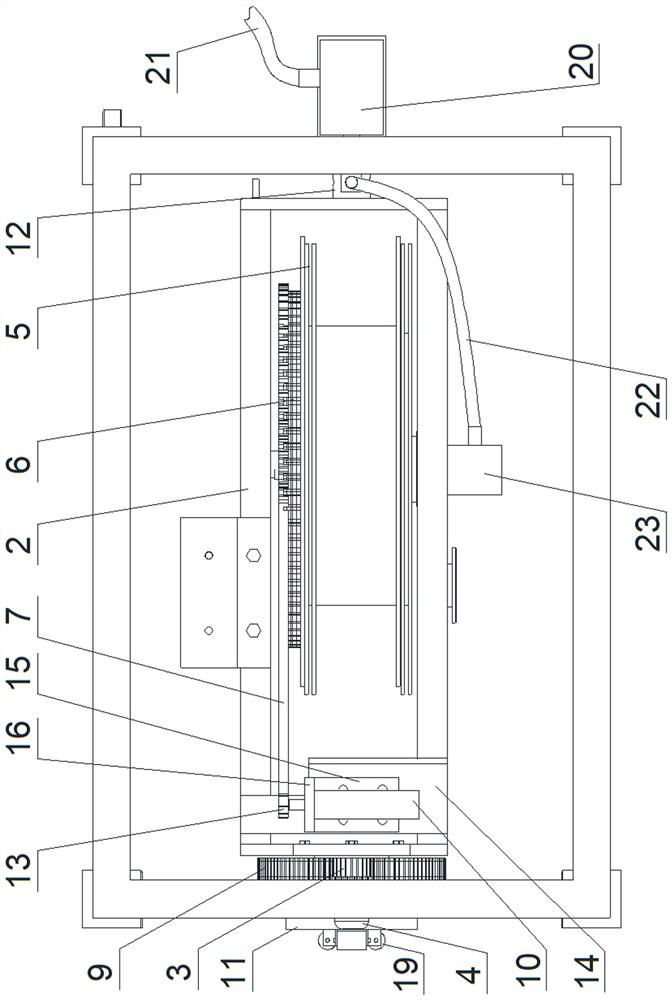

[0028] Such as Figure 1-4 As shown, a pipe coiler includes a main frame 1, an auxiliary frame 2 is installed in the main frame 1 to rotate along the length direction of the main frame 1, and a device for driving the auxiliary frame 2 is installed on the main frame 1 in a vertical direction centered on its central axis. The flip driving mechanism that rotates in a straight plane, the auxiliary frame 2 is installed in the auxiliary frame 2 along the height direction of the main frame 1, and the retracting roller 5 for rewinding the water pipe is installed, and the auxiliary frame 2 is installed on the auxiliary frame 2. The rotary drive mechanism that rotates in the vertical plane, the rotation plane of the retractable roller 5 and the rotation plane of the auxiliary frame 2 are perpendicular to each other. The water pipes can be retracted by the rotation of the retracting roller 5, and the twisted water pipes can be stretched by the turning of the auxiliary frame 2, so as to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com