Speed-change mechanism of variable-speed transmission

A technology of speed change mechanism and transmission, which is applied in the field of speed change transmission mechanism and speed change transmission, which can solve the problems of short service life, achieve long service life, avoid damage and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

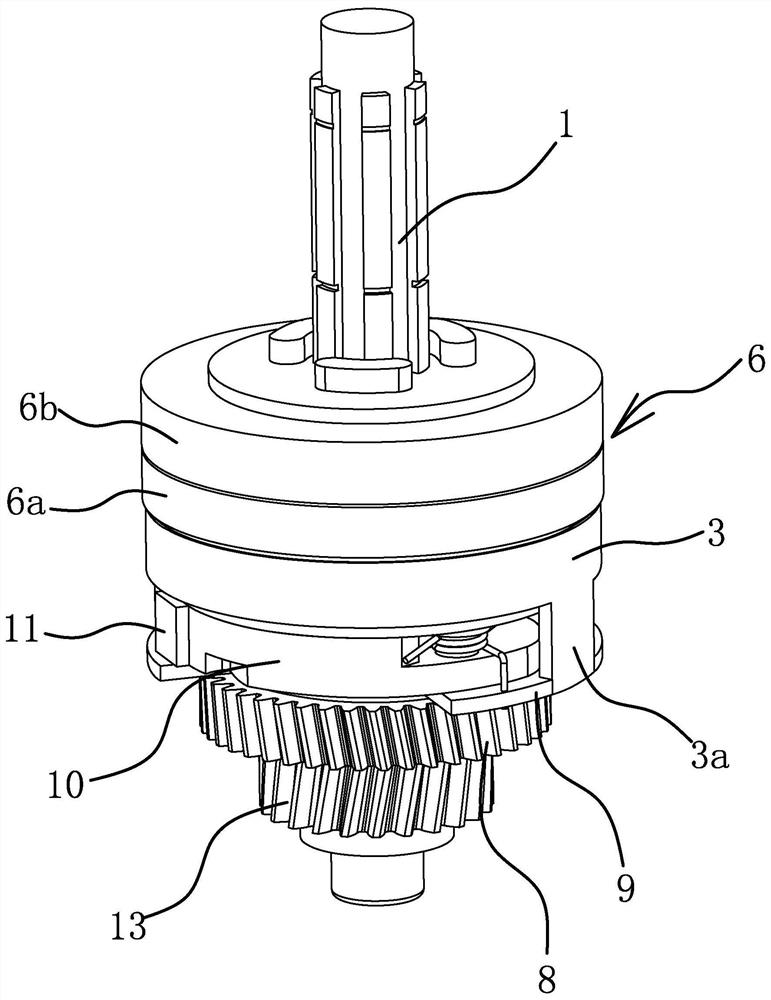

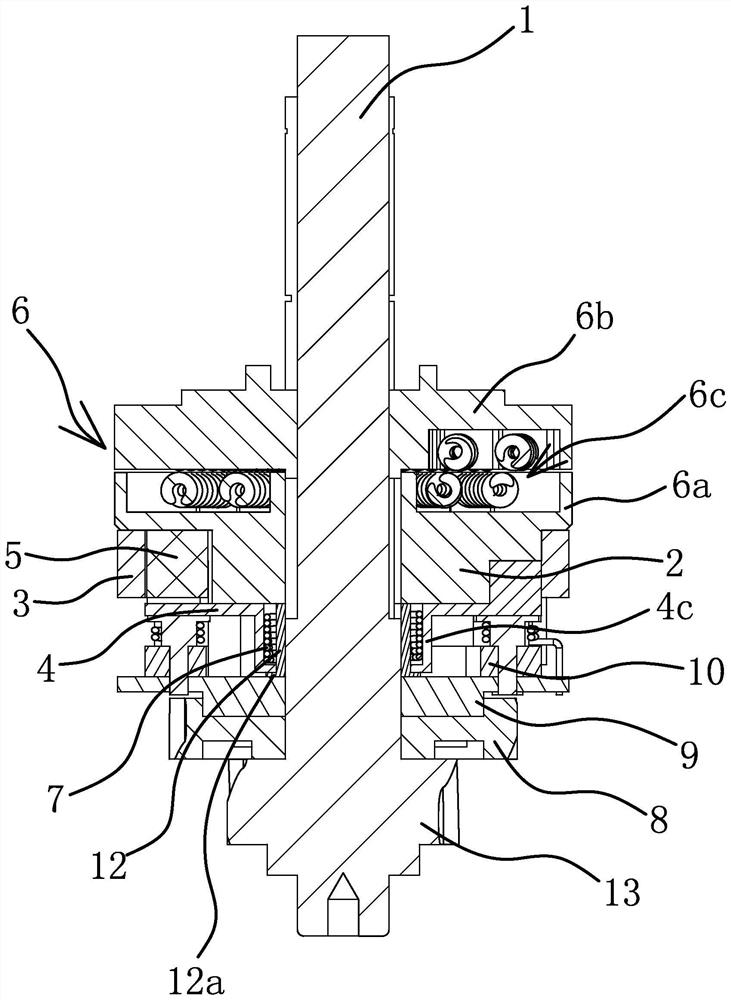

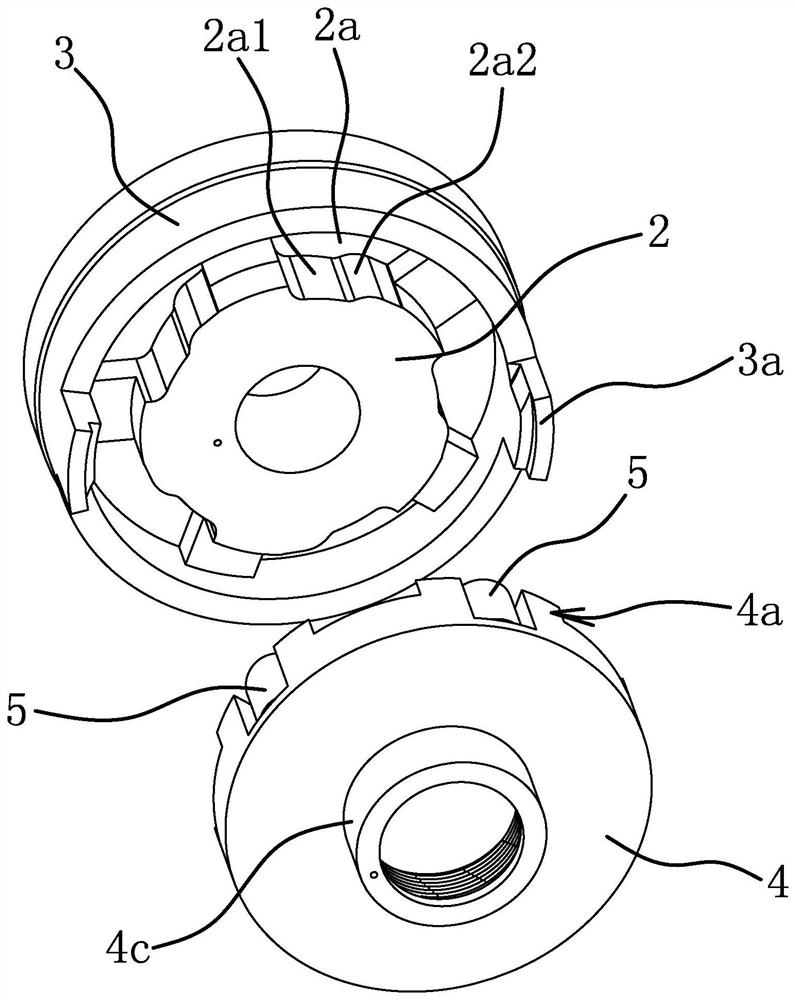

[0038] Such as Figure 1-Figure 4 As shown, the speed change mechanism of the variable speed transmission includes a main shaft 1, an inner ring 2 sleeved on the main shaft 1 and forming a linkage relationship with the main shaft 1, and an outer ring 3 axially fixed outside the inner ring 2 and capable of relative rotation. 1 is also sleeved with a rotatable control panel 4, and a clutch structure is provided between the outer ring 3 and the control panel 4. Between the outer ring 3 and the inner ring 2 there is a roller 5 controlled by the control disc 4, the outer side of the inner ring 2 has a movable groove 2a, the roller 5 is located in the movable groove 2a, when the control disc 4 rotates relative to the inner ring 2, it can The roller 5 is driven to move along the movable groove 2a so that the outer ring 3 and the inner ring 2 are linked or disengaged along the circumferential direction. The bottom wall of the movable groove 2a includes a relief surface 2a1 and a wedg...

Embodiment 2

[0048] The structure and principle of this embodiment are basically the same as those of Embodiment 1, except that in this embodiment, the wedging surface 2a2 is an oblique straight surface, and an obtuse angle is formed between the wedging surface 2a2 and the relief surface 2a1 horn.

Embodiment 3

[0050] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the movable groove is arranged on the inner wall of the outer ring 3, and the wedging surface faces the direction closer to the outer wall of the inner ring 2 relative to the abdication surface. Tilt setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com