Underwater cast-in-place concrete pile top pouring height control device and control method thereof

A technology of underwater concrete and height control, which is applied in the direction of sheet pile wall, foundation structure test, construction, etc., can solve the problem that the pouring height of the top of the underwater concrete pouring pile is difficult to control accurately, and achieve low production cost and economic benefits Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

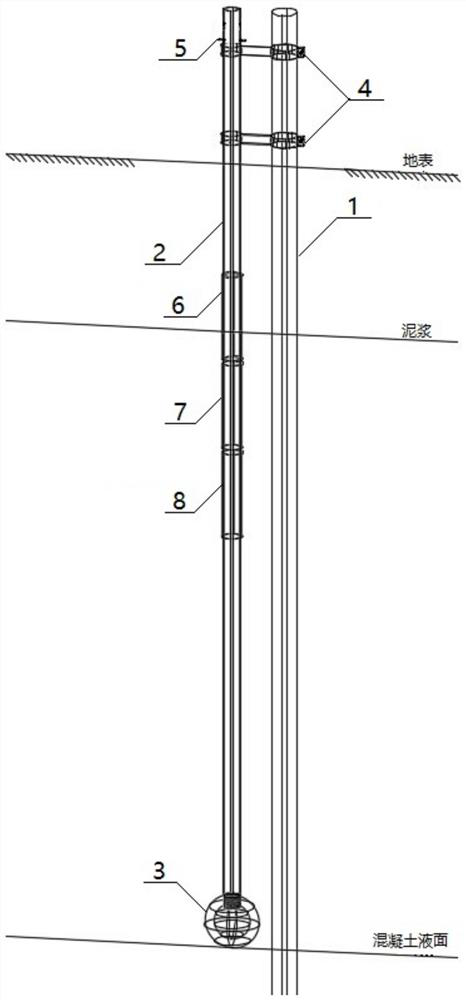

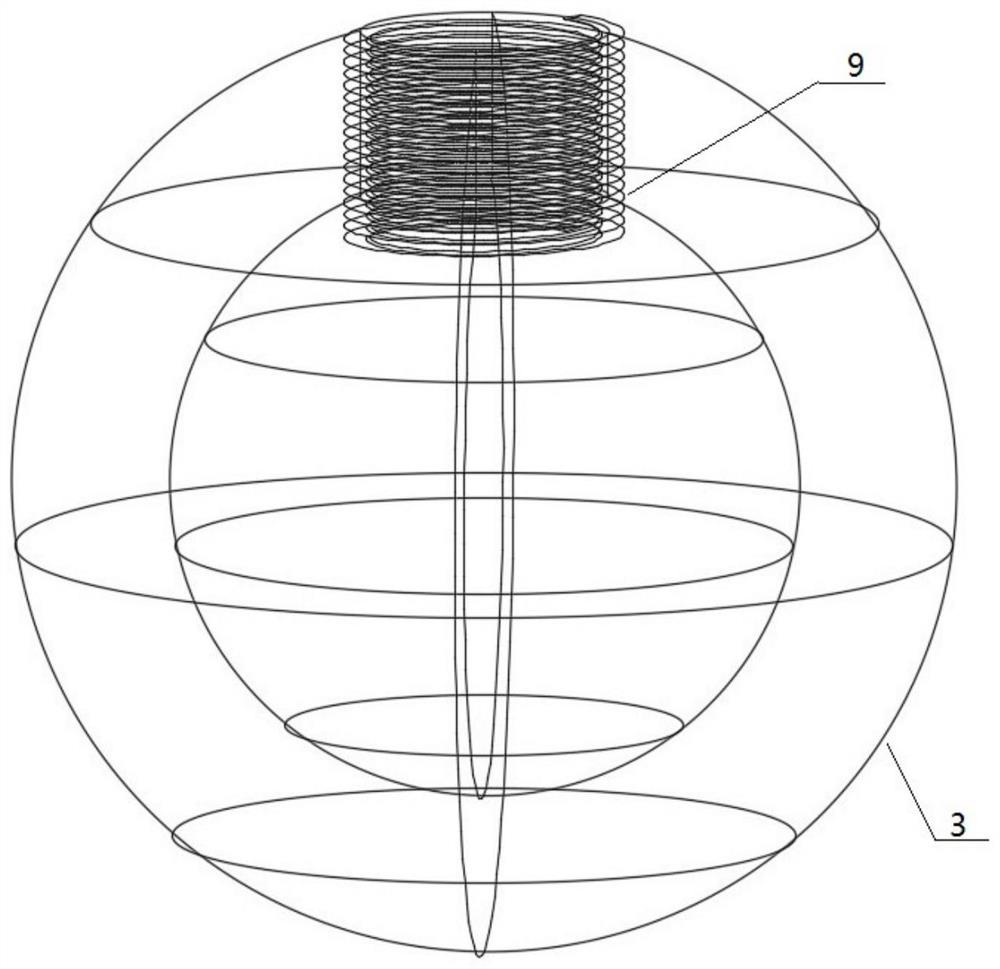

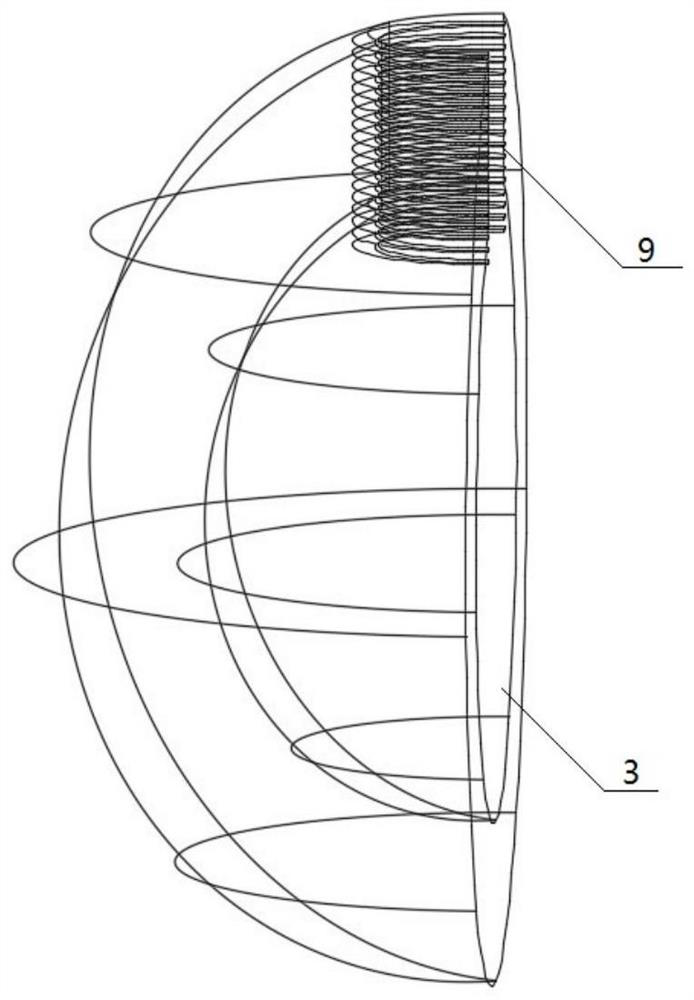

[0035] Such as figure 1 As shown, the present invention is an underwater concrete pouring pile top pouring height control device, including a position indicating rod 2, a buoyancy ball 3, a guide ring 4, a positioning card 5, a blue reflective film 6, a yellow reflective film 7 and a red reflective film Film 8. The position indicating rod 2 is a hollow through pipe, and the position indicating rod 2 is arranged parallel to the main reinforcement cage 1 side of the cast-in-place pile reinforcement cage through the guide ring 4; the buoyancy ball 3 is located at the bottom of the position indicating rod 2; There are blue reflective film 6, yellow reflective film 7 and red reflective film 8; an anti-sinking positioning card 5 is arranged above the position indicating rod.

[0036] Among them, the position indicating rod 2 is a lightweight hollow aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com