Drying system and clothes treating equipment comprising same

A drying system and drying chamber technology, which is applied in the field of drying systems and clothing processing equipment, can solve the problems of long drying time and high energy consumption, and achieve the effects of reducing burden, improving heat exchange efficiency, and improving dehumidification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

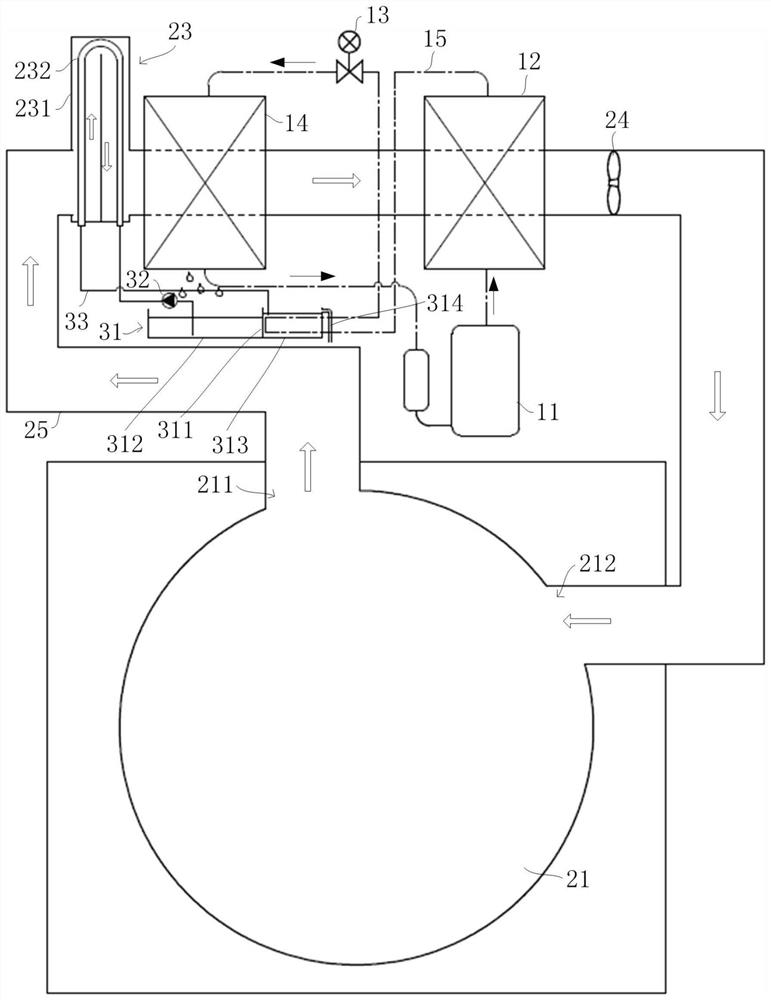

[0041] First refer to figure 2 , the first embodiment of the drying system of the present invention will be described. in, figure 2 It is a system diagram of the drying system in the first embodiment of the present invention.

[0042] As mentioned in the background technology, in the existing drying system, as the moisture content of the clothes in the drying chamber gradually decreases, the relative humidity in the drying chamber is also getting smaller and smaller, and the air heated by the condenser is in the drying chamber The lowering range of the medium temperature also decreases, and the temperature of the air entering the evaporator and condenser continues to rise, which leads to the gradual weakening of the dehumidification capacity of the evaporator, and the dehumidification effect is getting worse, which results in longer drying time for clothes and lower power consumption of the system. is also increasing.

[0043] Such as figure 2 As shown, in order to solv...

Embodiment 2

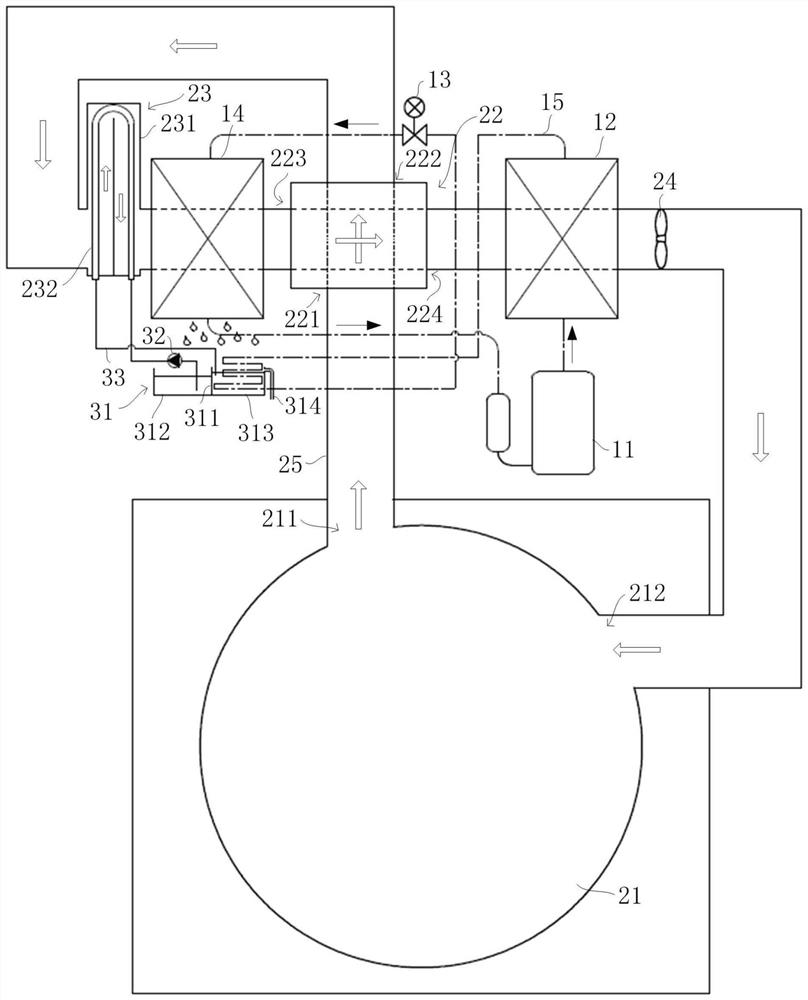

[0060] Refer below image 3 , to describe the second embodiment of the drying system of the present application. in, image 3 It is a system diagram of the drying system in the second embodiment of the present invention.

[0061] Such as image 3As shown, under the premise of keeping other structural settings unchanged in Embodiment 1, the drying system further includes a cascade heat exchanger 22, and the cascade heat exchanger 22 has a first inlet 221, a first outlet 222, a second inlet 223 and the second outlet 224, an air passage is formed between the first inlet 221 and the first outlet 222, another air passage is formed between the second inlet 223 and the second outlet 224, and the two air passages are intersected with each other , enabling cross-exchange of heat. The first inlet 221 communicates with the wet air outlet 211, the first outlet 222 communicates with the air inlet 2311 of the gas-liquid heat exchanger 23, the second inlet 223 communicates with the outle...

Embodiment 3

[0076] The present application also provides an integrated washing and drying machine, which includes a box body (not shown in the figure), an organic door is arranged on the box body, a water inlet assembly, a driving device and a washing tub assembly are arranged in the box body, The washing tub assembly includes an outer tub and an inner tub, the inner tub can hold clothes to be washed, the water inlet assembly can inject water into the outer tub, and the driving device can drive the inner tub to rotate so as to complete the washing of the clothes. This all-in-one washing and drying machine also includes the drying system described in the above embodiments, the outer cylinder is provided with a wet air outlet 211 and a dry air inlet 212, the outer cylinder, a gas-liquid heat exchanger 23, an evaporator 14, and a condenser 12 It is connected with fan 24 through air duct 25 to form an air circulation loop.

[0077] By setting the above-mentioned drying system in the washer-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com