Photocatalyst sterilizer and sterilization method thereof

A technology of photocatalyst and sterilizer, which is applied in the direction of chemical instruments and methods, light water/sewage treatment, special treatment targets, etc. It can solve the problems of reduced catalytic reaction efficiency, small contact surface, difficult to purify sewage odor, etc., to improve affinity Effects of sex and decomposition, reduction of liquid volume, and enhancement of efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

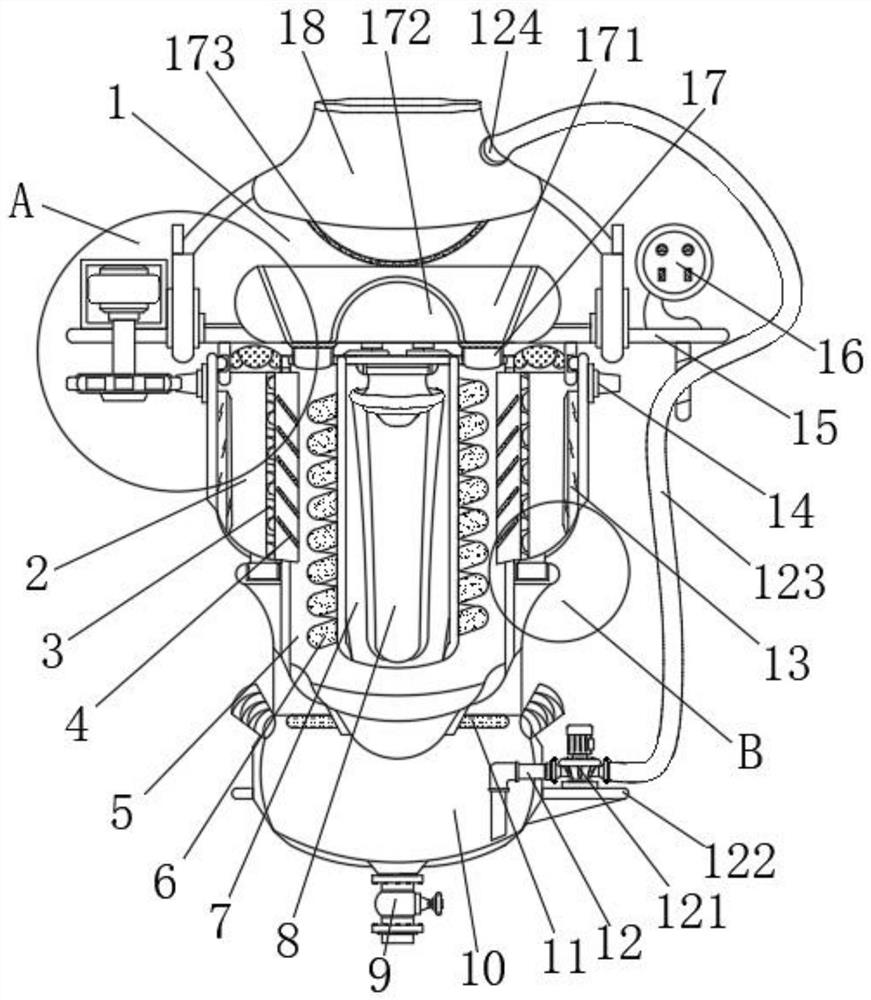

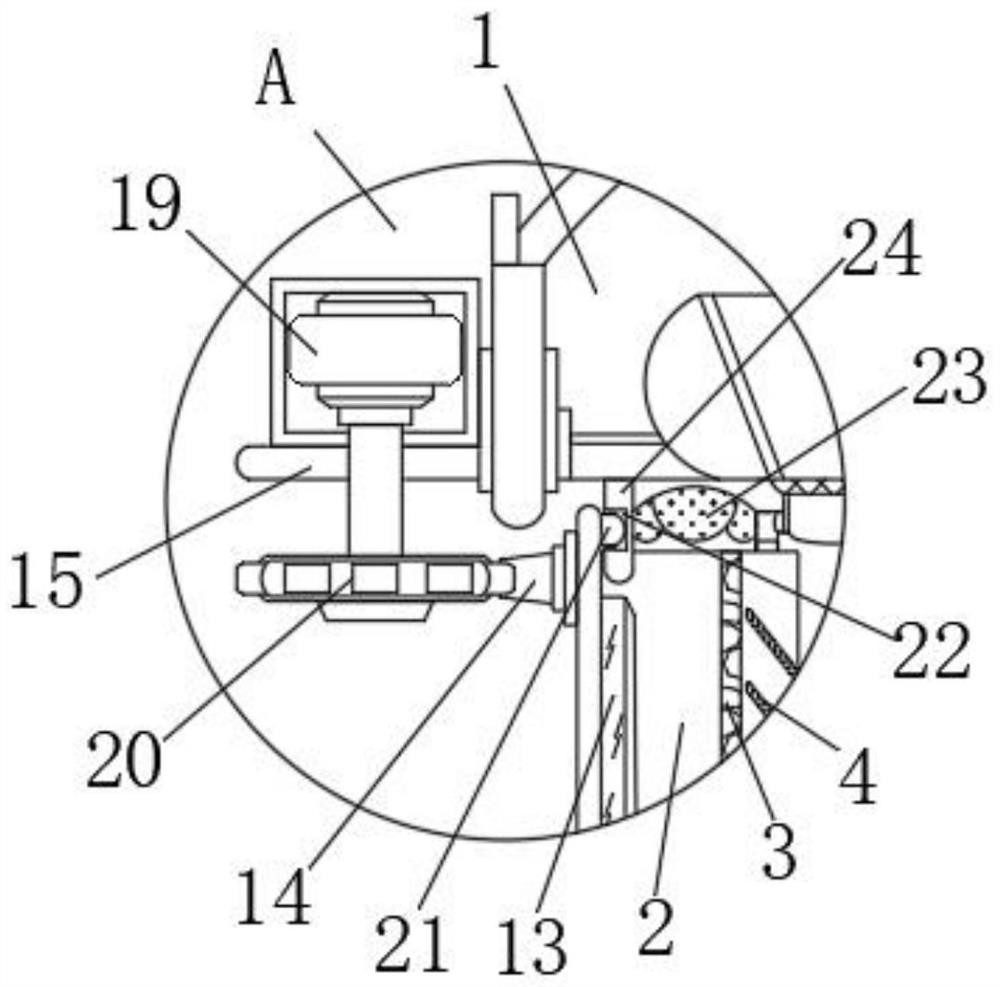

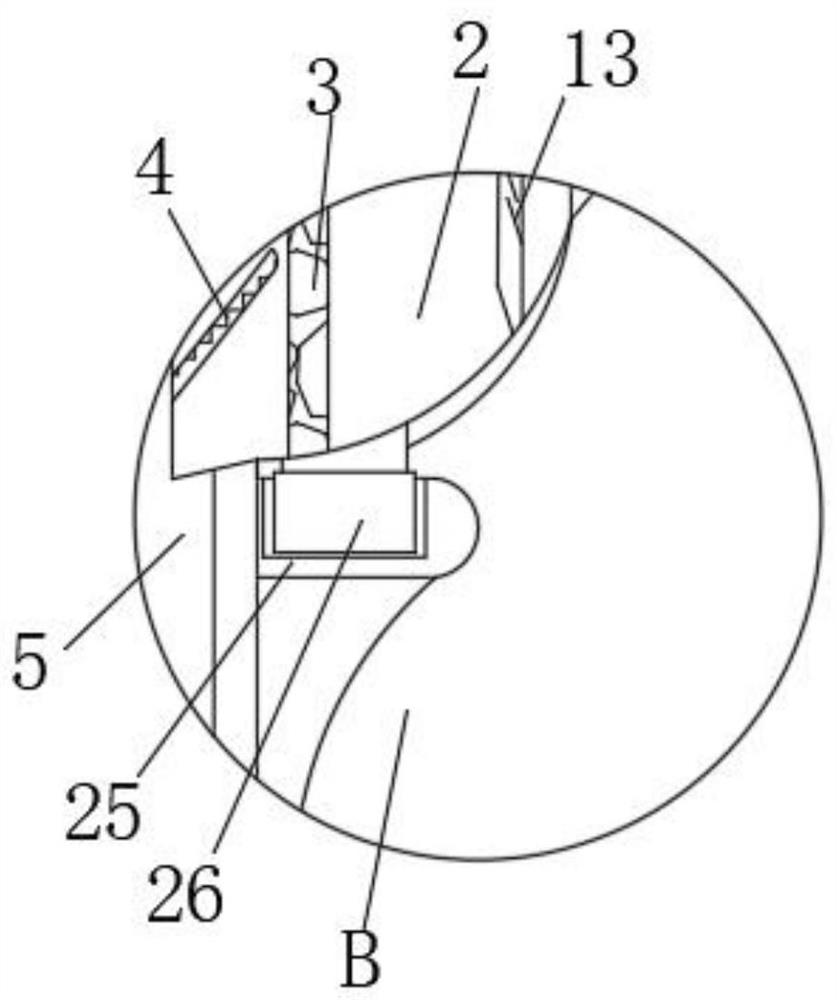

[0036] see Figure 1-8 , the present invention provides a kind of technical scheme: photocatalyst sterilizer, comprises mounting base 1, is characterized in that: the bottom of mounting base 1 both sides is provided with fixed table 15, and the top of a group of fixed table 15 is provided with console 16, another The top of the group fixing table 15 is provided with a servo motor 19, the output end of the servo motor 19 is provided with a gear 20, the middle position of the top of the mounting seat 1 is provided with an inlet 18, and the middle position of the bottom of the mounting seat 1 is provided with an ultraviolet sterilizer Lamp 8, a photocatalyst carrier B7 that cooperates with the ultraviolet germicidal lamp 8 is provided on the bottom of the mounting seat 1 near the outside of the ultraviolet germicidal lamp 8, and a photocatalyst carrier A6 that is bonded to each other is provided on the outside of the photocatalyst carrier B7, and the inside of the mounting seat 1 T...

Embodiment 2

[0043] see Figure 1-8 , the present invention provides a kind of technical scheme: photocatalyst sterilizer, comprises mounting base 1, is characterized in that: the bottom of mounting base 1 both sides is provided with fixed table 15, and the top of a group of fixed table 15 is provided with console 16, another The top of the group fixing table 15 is provided with a servo motor 19, the output end of the servo motor 19 is provided with a gear 20, the middle position of the top of the mounting seat 1 is provided with an inlet 18, and the middle position of the bottom of the mounting seat 1 is provided with an ultraviolet sterilizer Lamp 8, a photocatalyst carrier B7 that cooperates with the ultraviolet germicidal lamp 8 is provided on the bottom of the mounting seat 1 near the outside of the ultraviolet germicidal lamp 8, and a photocatalyst carrier A6 that is bonded to each other is provided on the outside of the photocatalyst carrier B7, and the inside of the mounting seat 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com