Automatic garbage can

A technology of garbage cans and garbage bags, applied in the field of garbage cans, can solve the problem that garbage cans cannot be automatically bagged and packed, so as to improve the use experience, ensure the use effect, and improve the user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

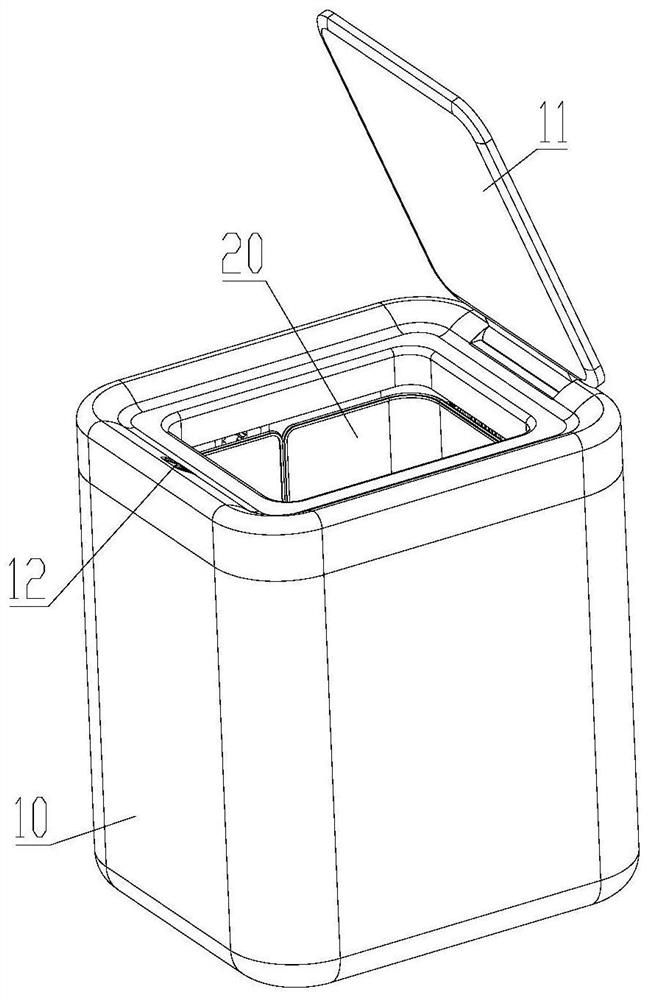

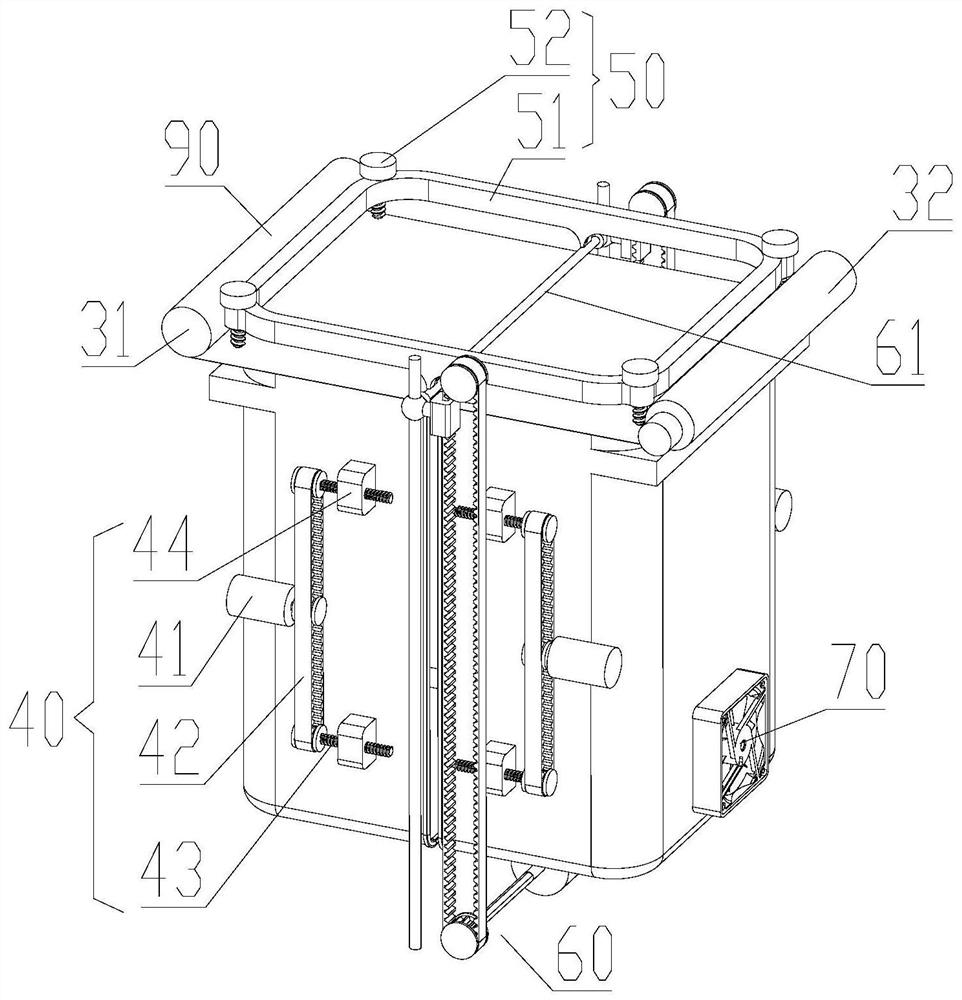

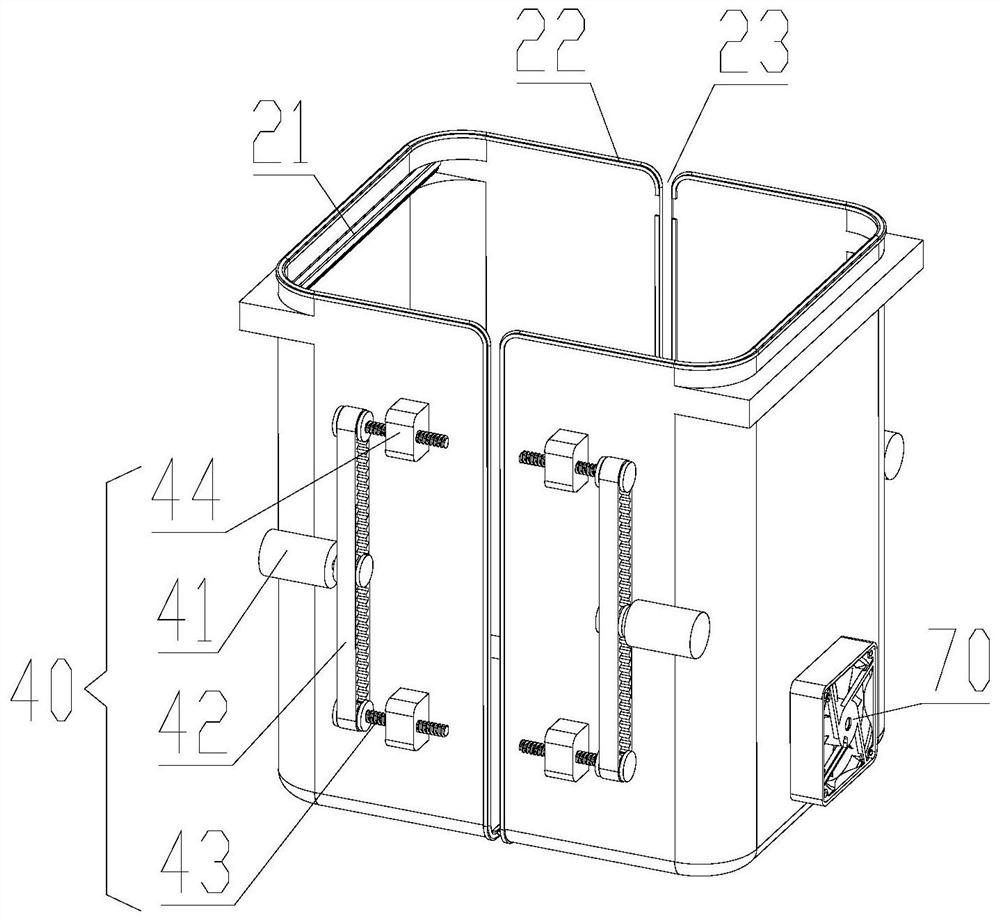

[0074] combine Figure 1-Figure 15 As shown, the automated trash can provided in this embodiment includes:

[0075] inner barrel 20;

[0076] The bag retracting mechanism 30 is adapted to drive at least one garbage bag 90 to move to the upper surface of the inner barrel 20 during the bag releasing stage;

[0077] The stretching mechanism 60 at least partially stretches the garbage bag 90 to the bottom of the inner bucket 20 along the vertical direction.

[0078] Preferably, the automatic garbage can includes a garbage can outer shell 10, the inner bucket 20 is placed in the garbage can outer shell 10, and the garbage can outer shell 10 is provided with a bung 11 suitable for opening and closing the garbage can .

[0079] The bag retracting mechanism 30 drives at least one garbage bag 90 to move to the upper surface of the mouth of the inner barrel 20 during the bag discharging stage, and preferably, the bag retracting mechanism 30 drives the garbage bag 90 to move in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com