Multifunctional manufacturing table for hardware machining

A multi-functional, workbench technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of cumbersome work, time-consuming and laborious manual cutting, manual loading and unloading, etc., to achieve convenient use and work efficiency. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

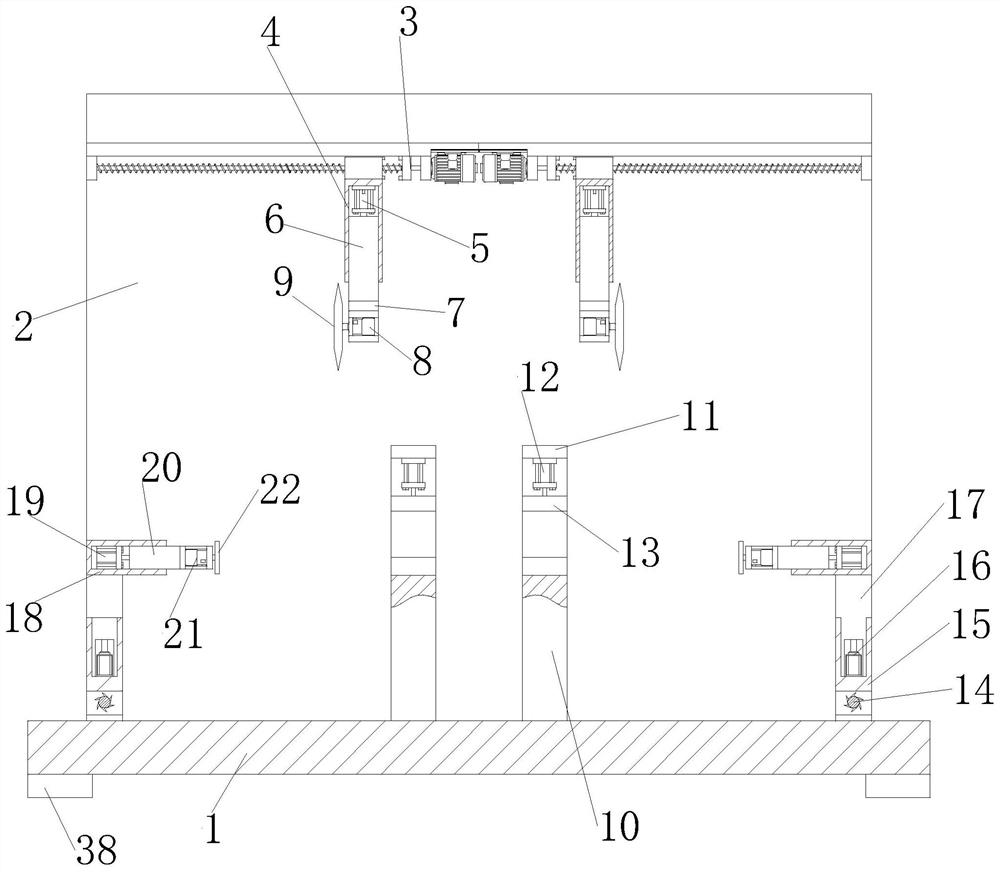

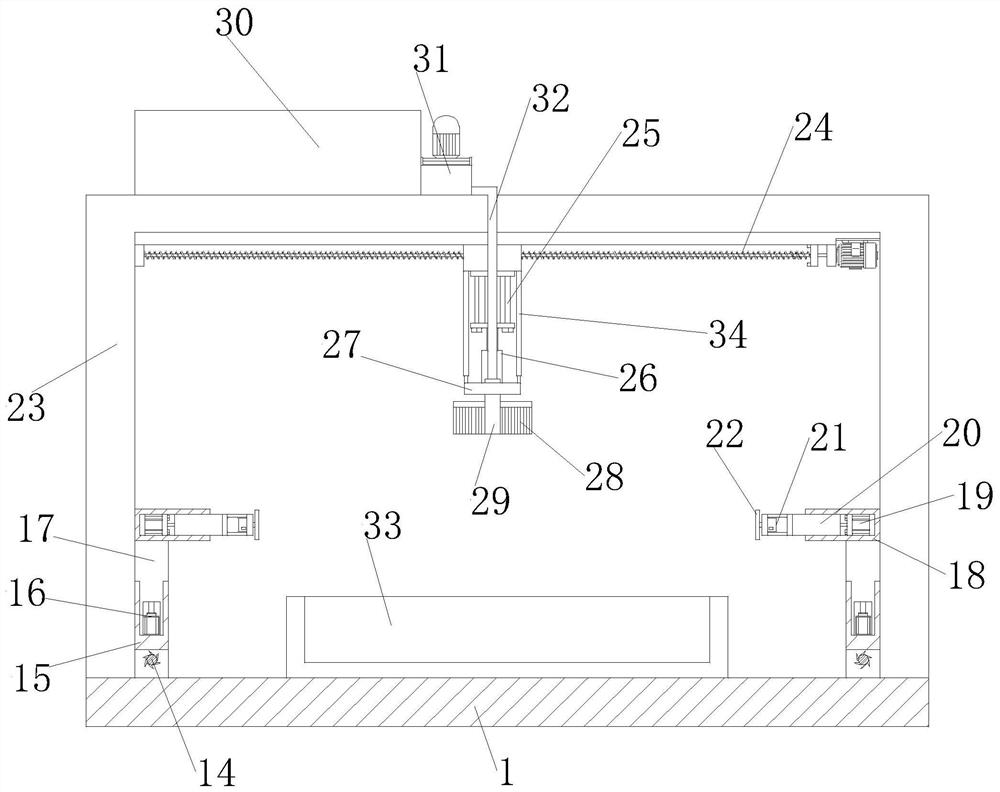

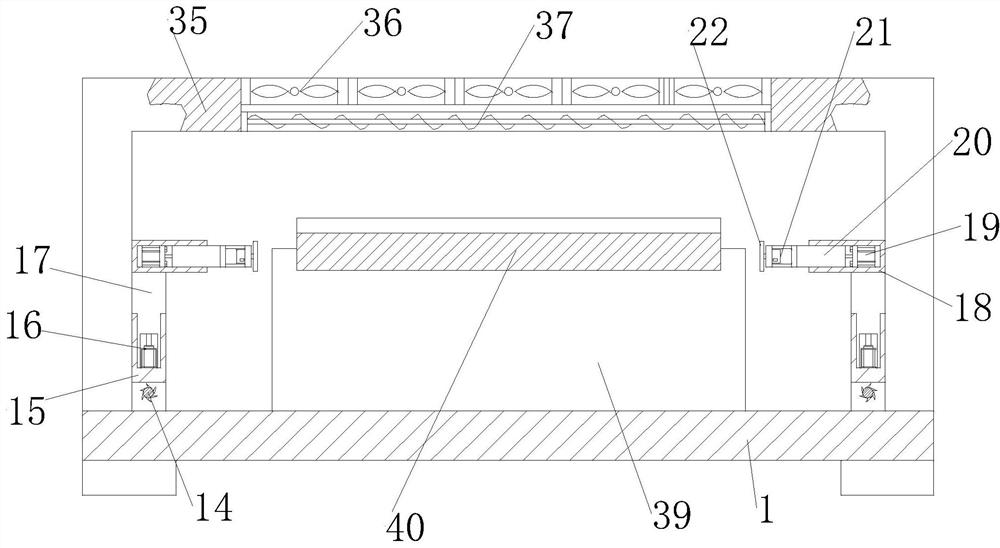

[0028] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a multi-functional production table for metal processing includes a workbench 1, a cutting structure is installed on the workbench 1, and a mobile fixing structure is installed on the workbench 1 and on one side of the cutting structure. A coating structure is installed on the platform 1 and located on one side of the mobile fixed structure, and a drying structure is installed on the workbench 1 and located on the side of the coating structure; the cutting structure includes: a mounting frame 2, a pair of the same first Straight pin screw module 3, a pair of mounting columns 4 with the same structure, a pair of first electric push rods 5 with the same structure, a pair of first connecting blocks 6 with the same structure, a pair of connecting plates 7 with the same structure, a For a rotary motor 8 with the same structure and a pair of cutters 9 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com