Rubber hose water tightness testing device

A testing device, a technology for rubber hoses, used in fluid tightness testing, measuring devices, and liquid/vacuum tightness measurement, etc., can solve the problem of inability to accurately detect the location of water leakage or air leakage in rubber hoses , Affecting the accuracy of rubber hose end detection, unable to block the end opening of the hose, etc., to achieve a wide range of use, maintain accuracy and precision, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

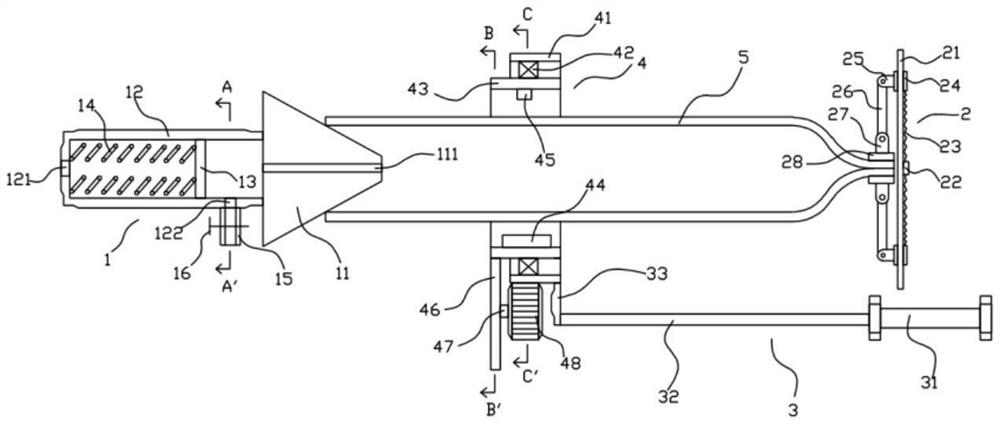

[0023] The rubber hose watertightness testing device of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

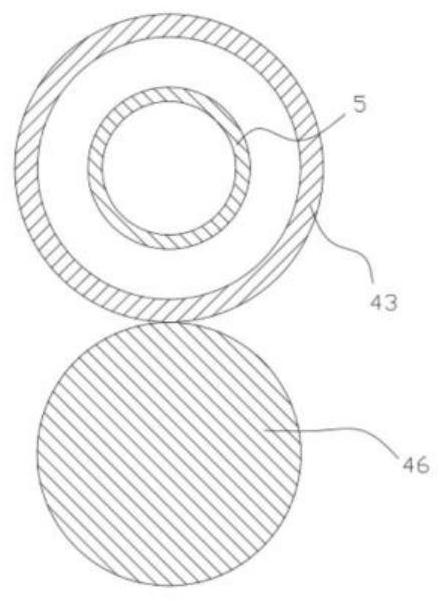

[0024] Such as Figure 1 to Figure 6 As shown, the rubber hose watertightness testing device of the present invention includes a blocking structure 1, a pressing structure 2 opposite to the blocking structure 1, a driving structure 3, a detection structure 4 arranged on the driving structure 3, and a terminal.

[0025] Such as figure 1 and figure 2As shown, the blocking structure 1 includes a blocking block 11, a concentrated frame 12 disposed on one side of the blocked block 11, a piston 13 disposed in the concentrated frame 12, and a first spring disposed on the piston 13. 14. The air intake pipe 15 arranged outside the centralized frame 12 and the valve 16 arranged on the air inlet pipe 15 . The blocking block 11 is preferably in the shape of a truncated cone, and the area of one end face of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com