Distributed flow shop scheduling method and system with batch delivery constraint

A workshop scheduling and distributed technology, applied in the direction of control/adjustment system, general control system, instrument, etc., can solve problems with many parameters and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

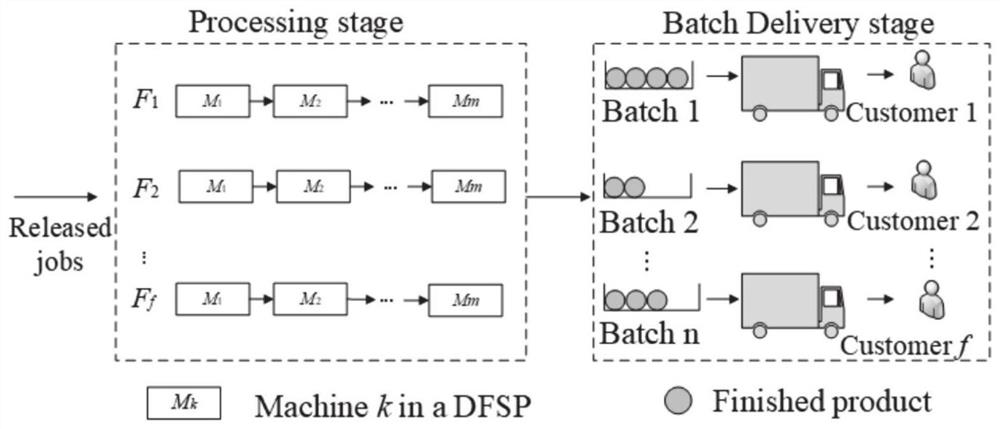

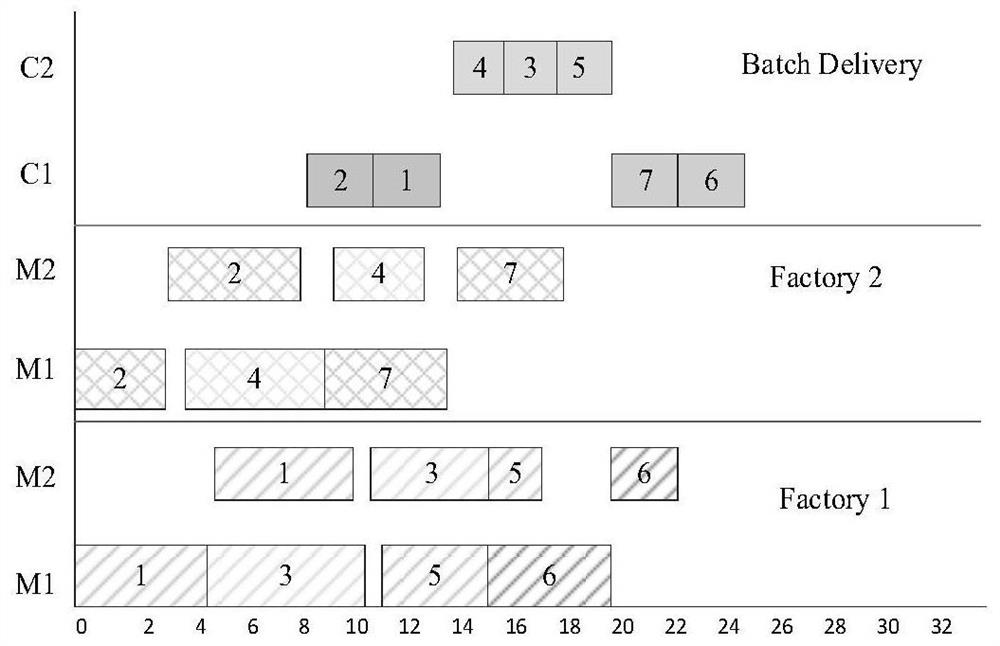

[0053] This embodiment discloses a distributed flow shop scheduling method with batch delivery constraints. Regarding the distributed replacement flow shop and batch delivery problem (DFSP-BD), the DFSP-BD that combines DFSP and batch delivery to the customer process is an optimization question. DFSP-BD is used to solve the integration of production and distribution in DFSP, it has two steps: processing jobs in the processing stage, batch delivery of products. Specific steps such as figure 1 shown.

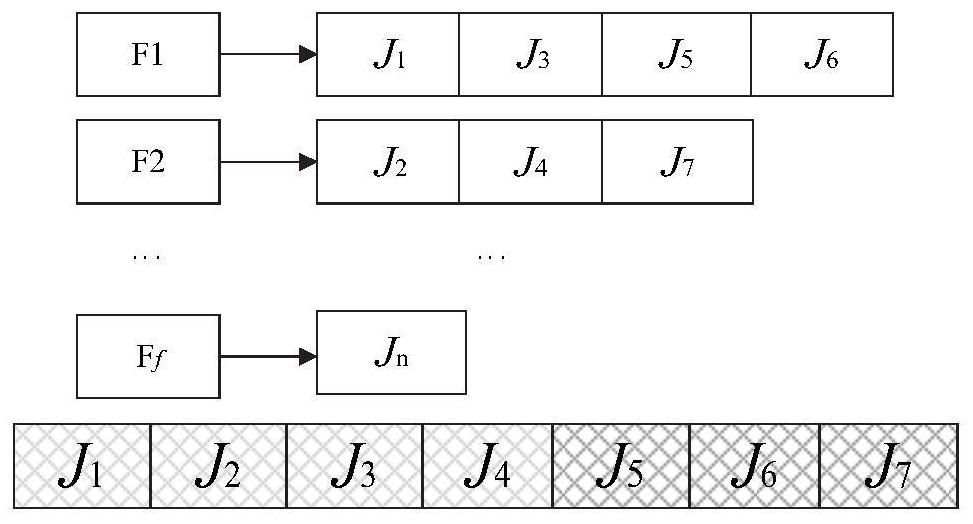

[0054] In the processing stage, first, a group of jobs J1, J2, J3..., Jn are randomly assigned to F factories F1, F2, F3..., Ff, and no changes are allowed after assignment. Then, in a distributed factory, jobs are processed on m identical machines, M1, M2, M3, ..., MM in the same order, and the processing time of the first machine in the factory is 0. In the end, a machine can only handle one job at a time. Each job must be processed on the previous machine and then processed...

Embodiment 2

[0149] The purpose of this embodiment is to provide a computing device, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, the steps of the methods in the above-mentioned embodiments are realized. .

Embodiment 3

[0151] The purpose of this embodiment is to provide a computer-readable storage medium.

[0152] A computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the steps of the methods in the above implementation examples are executed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com