Detection system and method for measuring final straightness of welded rail

A detection system and detection method technology, applied in the direction of electric/magnetic roughness/irregularity measurement, measuring device, mechanical measuring device, etc., can solve the problems of measurement accuracy error, reduce error, reduce operation complexity, Run Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

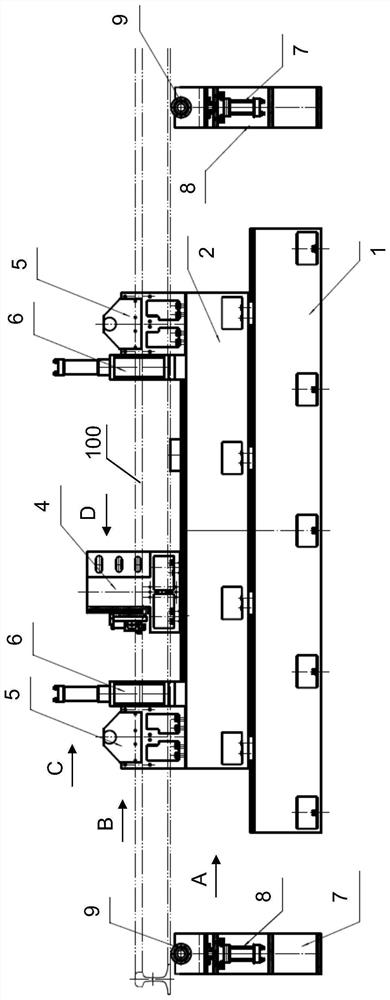

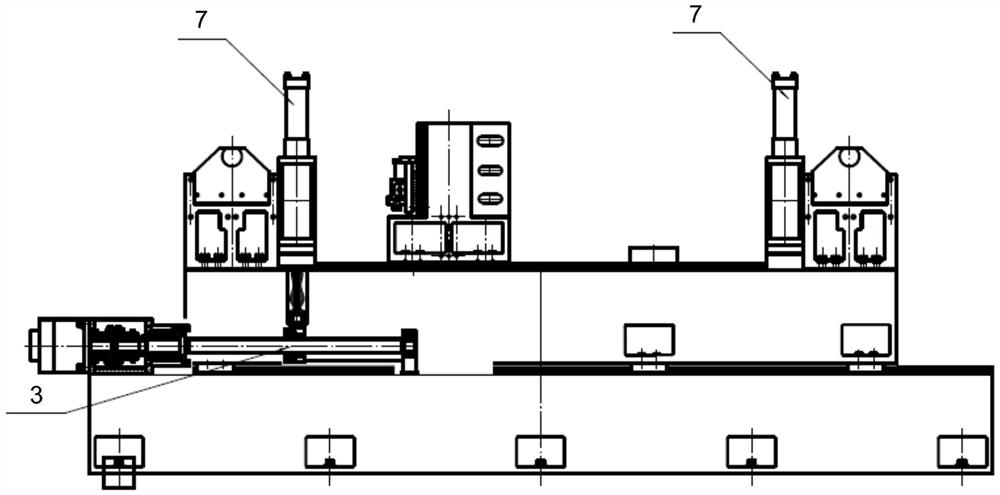

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0053] Please combine Figure 1 to Figure 4 As shown, a detection system for measuring the final straightness of a welded rail provided by the present invention is installed on a non-movable foundation platform along the working direction of the measured rail 100 as a whole. The detection system is 3.3 meters long and 0.6 meters wide. , 1.2 meters high, including:

[0054] The base 1 is arranged along the working direction of the rail 100 .

[0055] The moving box body 2 moves left and right along the working direction of the steel rail 100 on the base 1 through the platform moving part 3 .

[0056] The measuring frame box 4 is installed on the mobile box 2 for measuring and collecting welding seam data on the rail 100 .

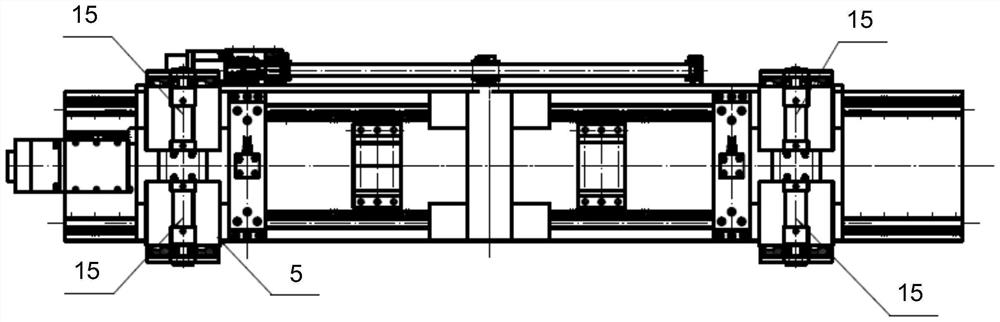

[0057] There are two sets of clamping parts 5, which are respectively installed at the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com