Cobweb-shaped combined sand barrier with functions of preventing sand gathering and sand burying

A sand barrier and sand burial technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of lack of dredging and diversion, increased cost of grass grids, huge total investment, etc., saving laying materials, reducing The effect of collecting and burying sand and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

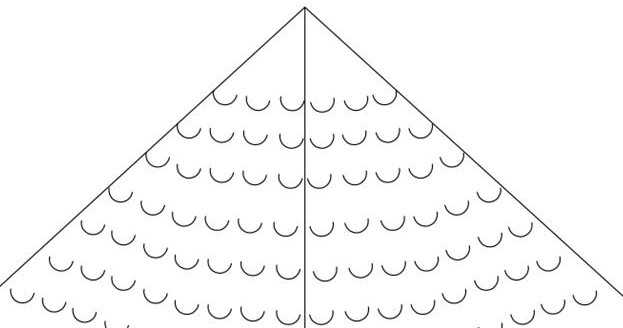

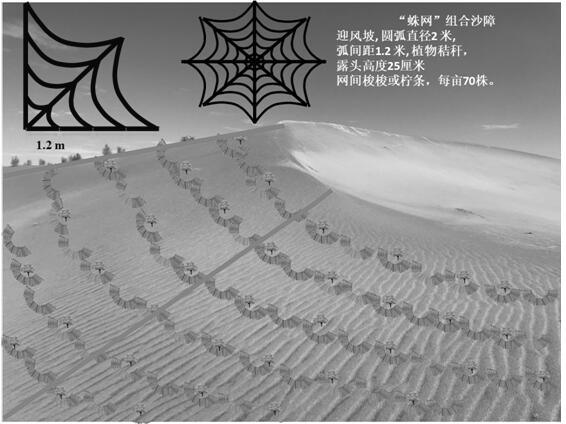

[0021] In low (dune height less than 5 m) and relatively flat quicksand areas (slope ≤ 30°), use straw (wheat straw, rice straw, sunflower stalks, sorghum stalks, corn stalks or branches) as raw materials to roll "spider web"-shaped combinations Sand barriers, combined sand barriers are composed of arc net sand barriers and linear sand barriers, arc net sand barriers are composed of multi-layer arc nets, and each layer of arc nets is composed of several elliptical arc sand barrier connections. According to the topography and quicksand area, roll the elliptical arc sand barrier. When the rolling is completed, the column spacing of the elliptical arc sand barriers arranged in parallel outwards along the top of the dune is 2 m, the row spacing of each layer of elliptical arc sand barriers is 1 m, and the distance between two adjacent linear sand barriers on the windward slope includes 3 ~4 elliptical arc sand barriers, including 2~3 elliptical arc sand barriers between two adjace...

Embodiment 2

[0024] The slope of the sand dunes is ≤30°, and the "spider web"-shaped combined sand barrier is rolled with wheat straw or straw as raw material. The "spider web" sand barrier is composed of arc net sand barriers and linear sand barriers. figure 1 . The arc radius of the semi-circular sand barrier is 1.5 m. When laying, the column spacing of the semi-circular sand barriers arranged in parallel outwards along the top of the dune is 2 m, and the row spacing of each semi-circular sand barrier connection is 1 m. Outcrop grass The height is 25 cm, the top of the semi-circular arc is facing the direction of the main sand flow, and the distance between the linear sand barriers is 1.5-2.5 m. Each layer of arc sand barriers between two adjacent linear sand barriers on the windward slope consists of 3 to 4 semicircular sand barriers, and each layer of arc sand barriers between two adjacent linear sand barriers on the upwind slope consists of 2 to 3 All of them are composed of semi-ci...

Embodiment 3

[0027] Sand dune slopes meet the requirements of 30°figure 1 . The arc radius of the semi-circular sand barrier is 1.2 m. When laying, the column spacing of the semi-circular sand barriers arranged parallel to the outside along the top of the dune is 1.5 m, and the row spacing of each layer of semi-circular sand barriers is 1 m. The height is 25 cm, the top of the arc is directly opposite to the direction of the main sand flow, and the distance between the linear sand barriers is 1.5-2.5 m. Each layer of arc network between two adjacent linear sand barriers on the windward slope is composed of 5 to 7 semicircular sand barriers, and each layer of arc network sand barriers between two adjacent linear sand barriers on the upwind slope is composed of 3 to 4 semicircular sand barriers. Composed of arc sand barriers.

[0028] When gravel, cobblestone, gravel or soil are used as raw materials, first pile sand to form a semicircular and linear sand barrier with a height of 25 cm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com