Multi-stage refrigeration control method of railway vehicle air conditioning unit

A technology for air conditioning units and refrigeration control, which is applied in the heating/cooling of railway vehicles, railway car body parts, transportation and packaging, etc. The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

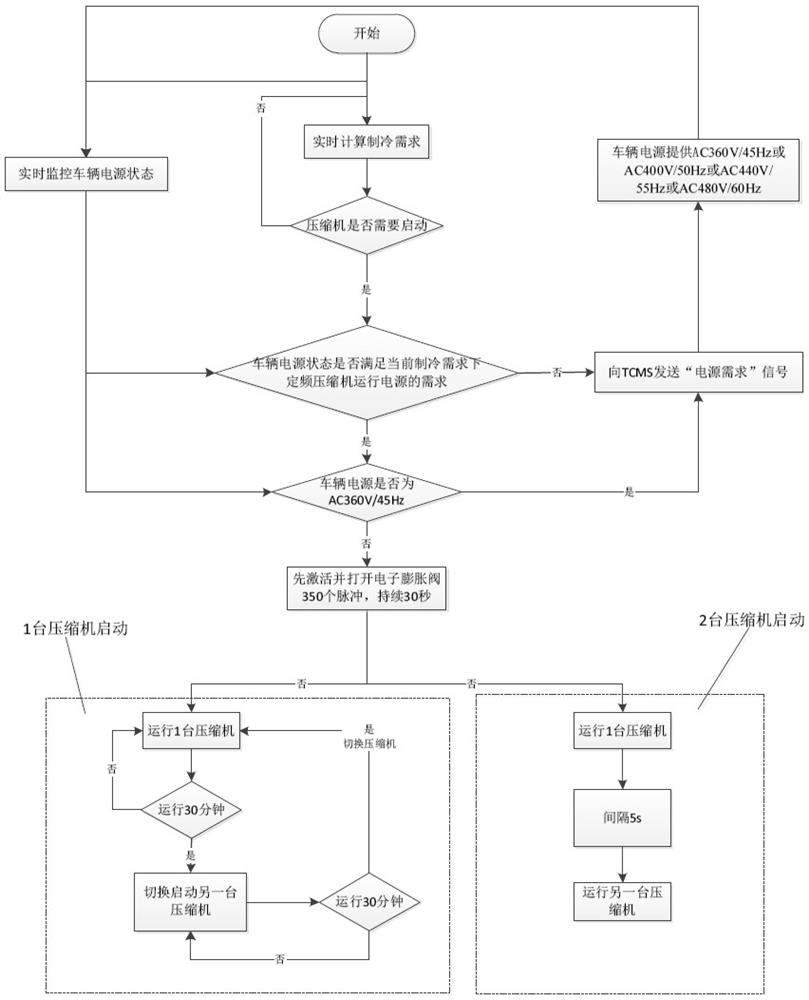

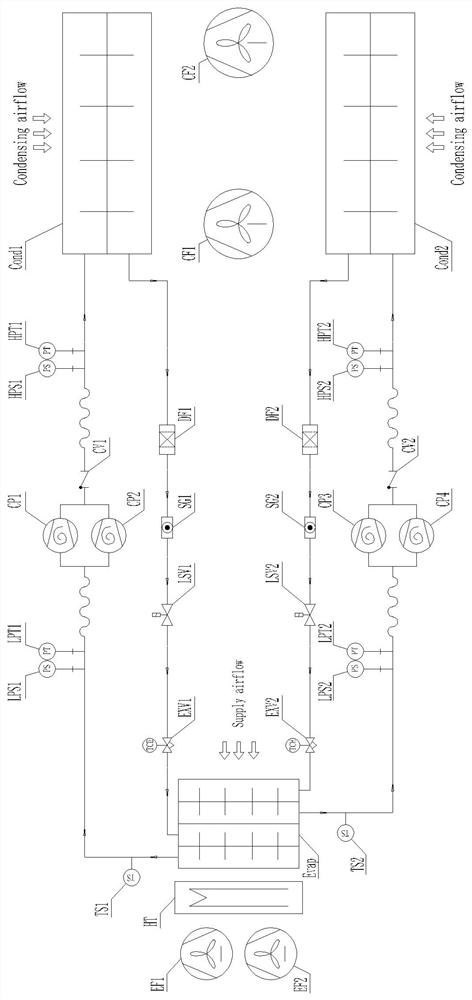

[0013] The present invention provides a multi-stage refrigeration control method for rail vehicle air-conditioning units, which is based on the air-conditioning units with two fixed-frequency compressors arranged in parallel in a refrigerant circulation loop, comprising the following steps.

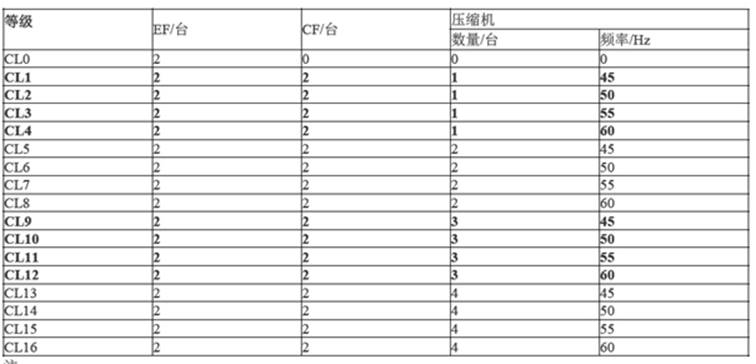

[0014] Step A, calculate the cooling demand in real time, perform step B when one fixed-frequency compressor needs to be operated, and perform step C when two fixed-frequency compressors need to be operated.

[0015] Step B. Detect whether the power supply status of the vehicle satisfies the power requirements for the operation of the fixed-frequency compressor under the current cooling demand. If not, send a power demand signal for changing the frequency conversion voltage to the vehicle control system. When it is detected that the power supply status meets the cooling demand, control a fixed frequency compressor. The frequency compressor is running under the current power state. The pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com