Efficient battery replacing station for electric commercial vehicle

A technology for commercial vehicles and battery swapping stations, which is applied in the field of high-efficiency swapping stations for electric commercial vehicles, and can solve the problems of complex battery swapping equipment, impossibility of promotion and popularization, and inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

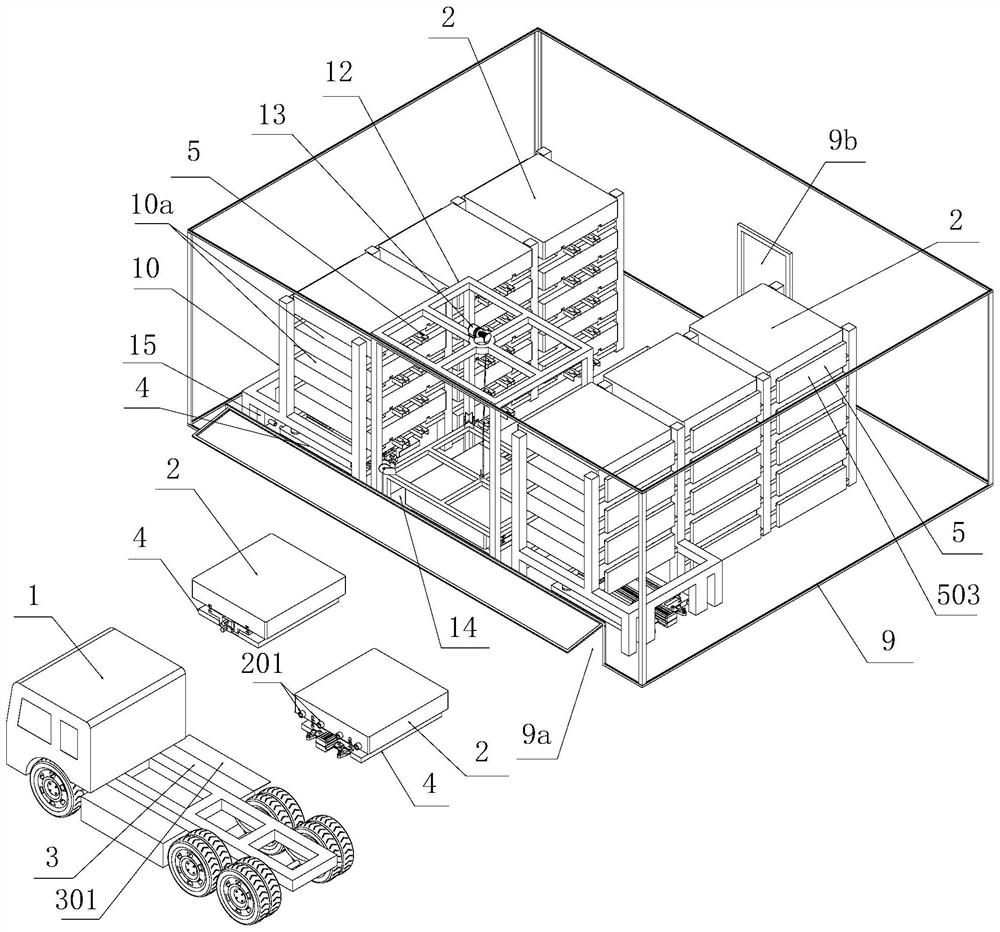

[0075]Example: Combine belowFigure 1~15 The detailed description of the high-efficiency switch station for electric commercial vehicles provided by the present invention is as follows:

[0076]First asfigure 1 As shown, from the overall point of view, the present invention is composed of the battery pack 2, the battery exchange trolley 4, and the charging house.

[0077]The power driving part of the electric commercial vehicle 1 mentioned in the present invention has not been improved, and the battery compartment 3 adopts a horizontal form to install the battery pack 2.

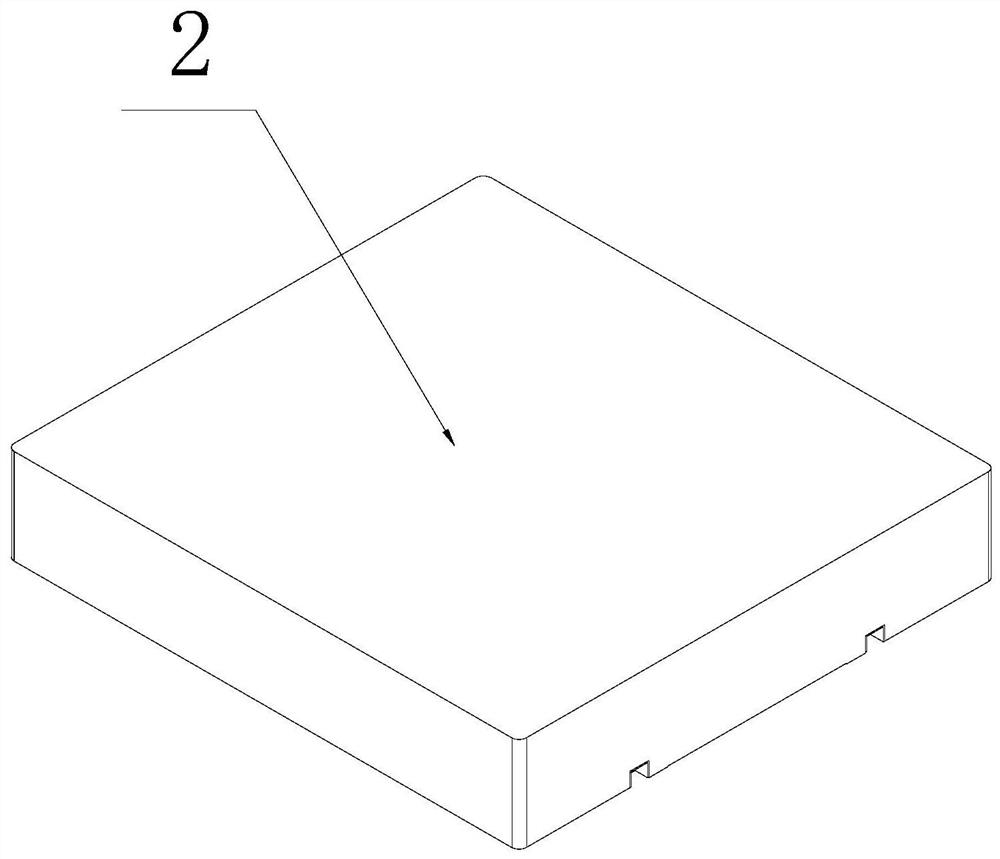

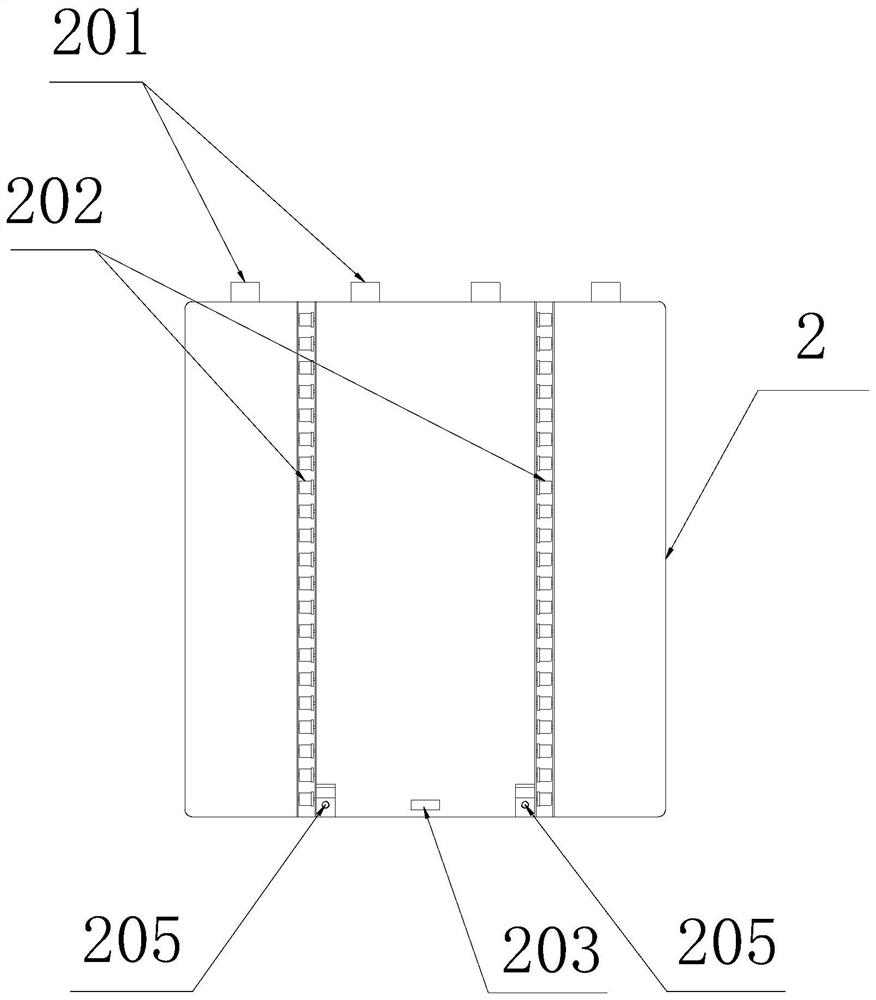

[0078]Combine firstFigure 2~4 To illustrate the battery pack 2, the battery pack 2 in the present invention is designed in a rectangular parallelepiped shape, and is made into multiple sizes according to the load of the electric commercial vehicle 1, and corresponds to the battery compartment 3 of different sizes. For example, the electric commercial vehicle 1 exemplified in this embodiment is a conventional electric contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com