Denitration SCR catalyst supporting and hoisting device based on economizer grading transformation

A technology of SCR catalyst and economizer, which is applied in separation methods, feed water heaters, and dispersed particle separation, etc., can solve the problems of difficult layout space requirements, complex support structures, and difficult construction, etc., to meet the layout space requirements, Good economy and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

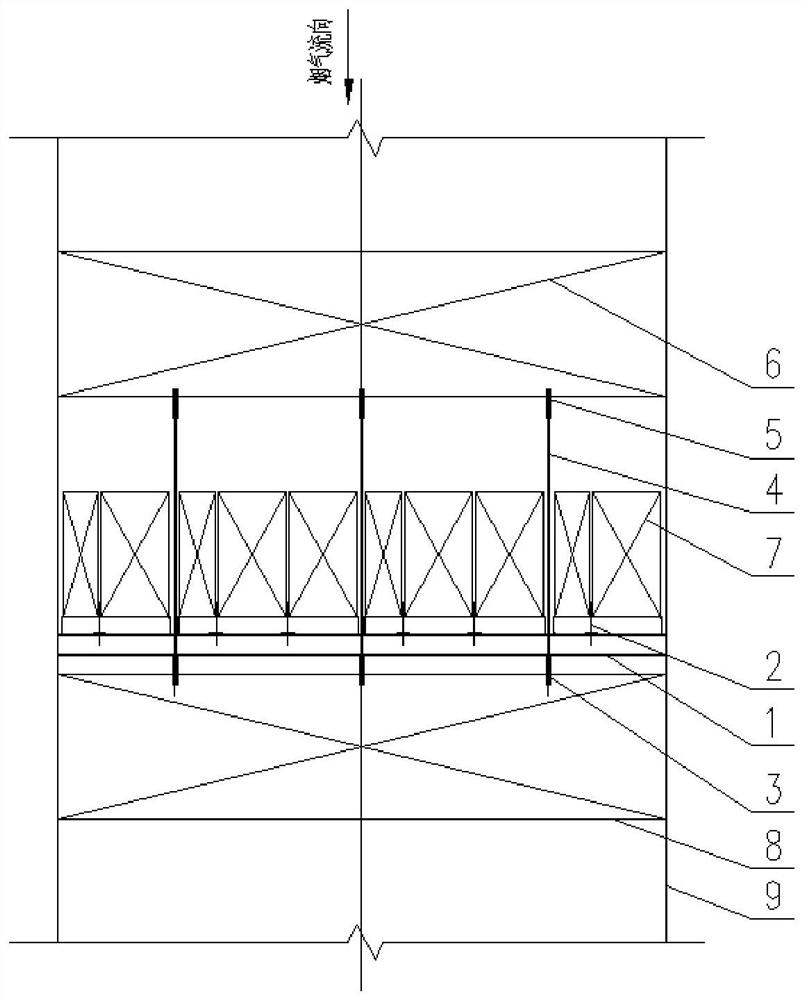

[0017] refer to figure 1 , the denitrification SCR catalyst supporting and hanging device based on economizer graded transformation according to the present invention includes economizer hanging plate 4, upper economizer 6, lower economizer 8, catalyst supporting main beam 1 and several catalyst supporting secondary beams 2. The upper end of the economizer hanging plate 4 is connected to the upper-level economizer 6, the lower end of the economizer hanging plate 4 is connected to the lower-level economizer 8, and the catalyst support main beam 1 is located between the upper-level economizer 6 and the lower-level economizer. Between the coal burner 8, and the catalyst support main beam 1 is connected with the middle part of the economizer hanging plate 4, each catalyst support sub-beam 2 is fixed on the catalyst support main beam 1, and the catalyst module 7 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com