Safety inspection method and inspection system

An inspection system and safe technology, applied in the field of inspection management, can solve the problems of false detection, recording, non-inspection, etc., to achieve the effect of improving reliability, reducing monitoring costs, and ensuring intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

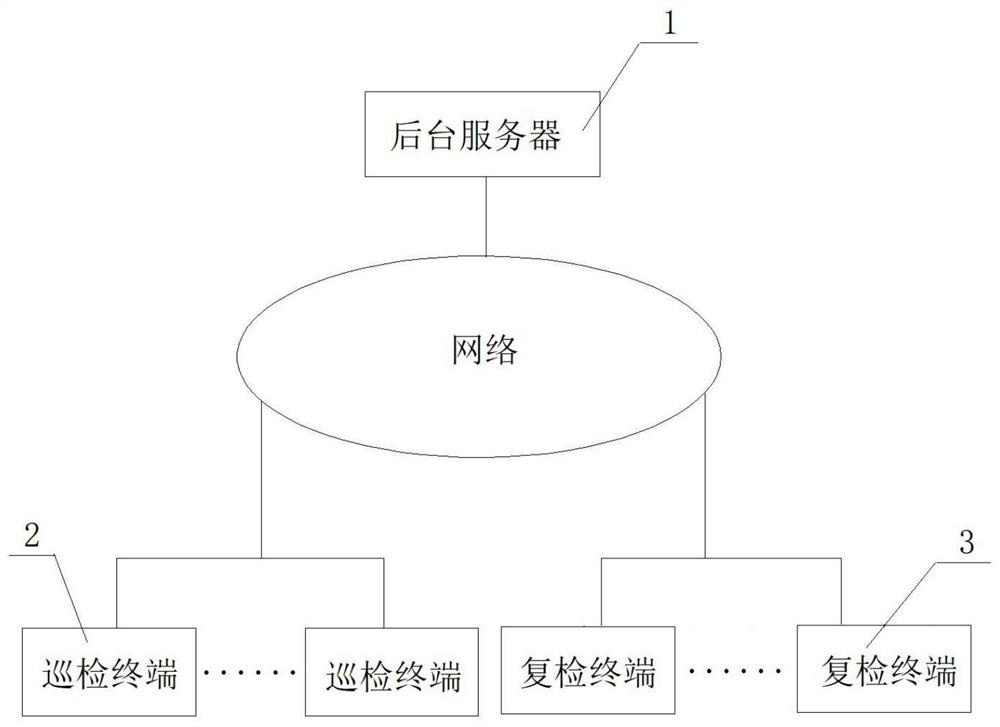

[0028]Such asfigure 1 As shown, as the schematic diagram of the interaction structure of the back-end server 1 and the inspection terminal 2 and the re-inspection terminal 3 in this embodiment, the back-end server 1 and multiple inspection terminals 2 are interactively connected through the network, and the back-end server 1 and multiple re-inspection terminals The terminal 3 is interactively connected through the network.

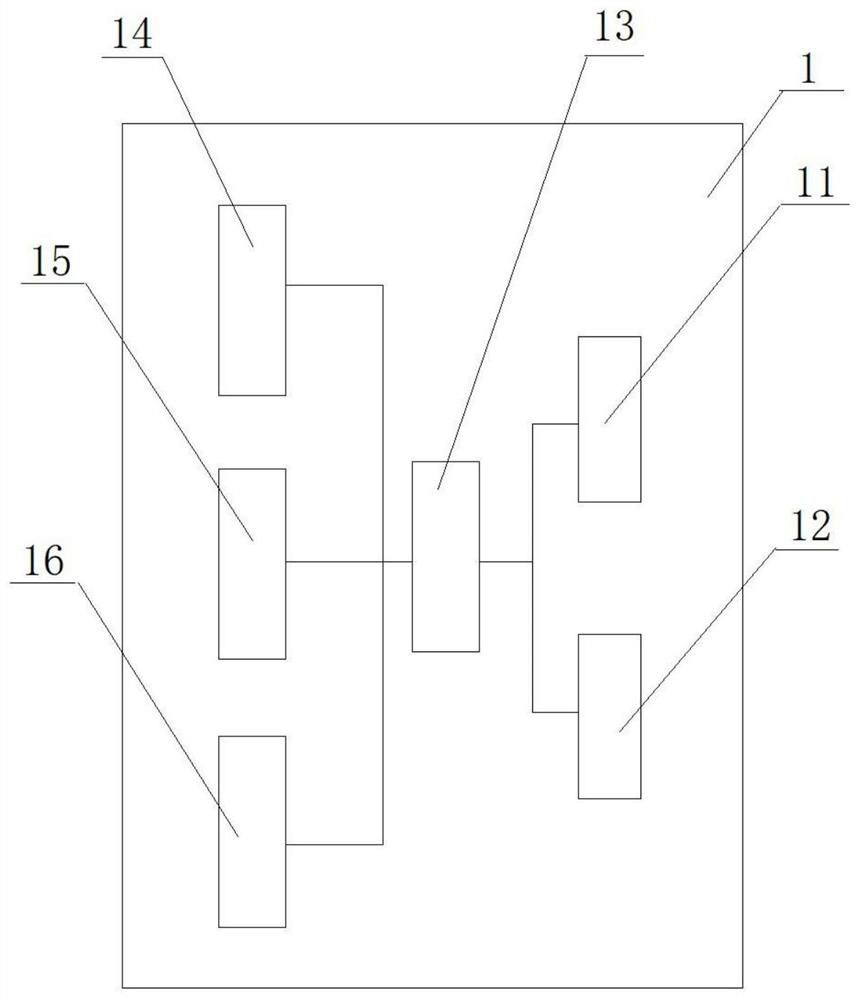

[0029]Such asfigure 2 As shown, it is a schematic structural diagram of the internal modules of the background server 1, including an instruction sending module 11 for sending inspection instructions to each inspection terminal 2, and a data receiving module 12 for receiving inspection data sent by each inspection terminal 2. , Data storage module 16 for storing pre-stored data information, data processing module 13 for processing and comparing inspection data, route generation module 15 for generating inspection routes, and location coordinates corresponding to ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com