Carpet beater for treating dust with airflow

A flapper and carpet technology, applied in textiles and papermaking, mechanical cleaning, high-pressure cleaning, etc., can solve the problems of low efficiency, longer consumption, unfavorable people's living and life, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

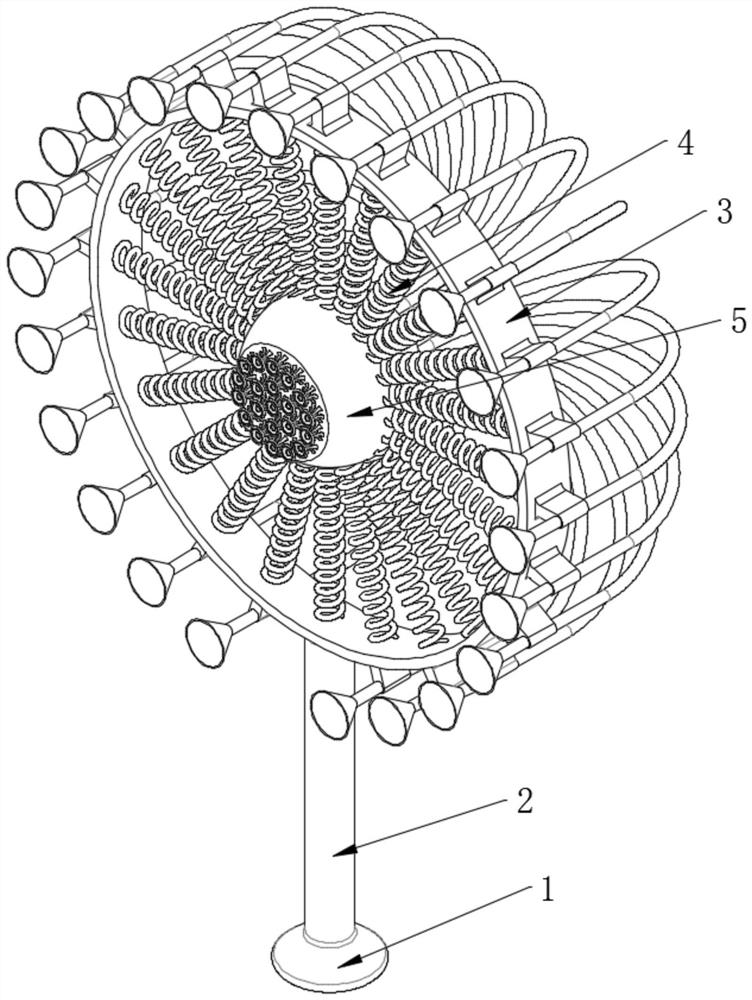

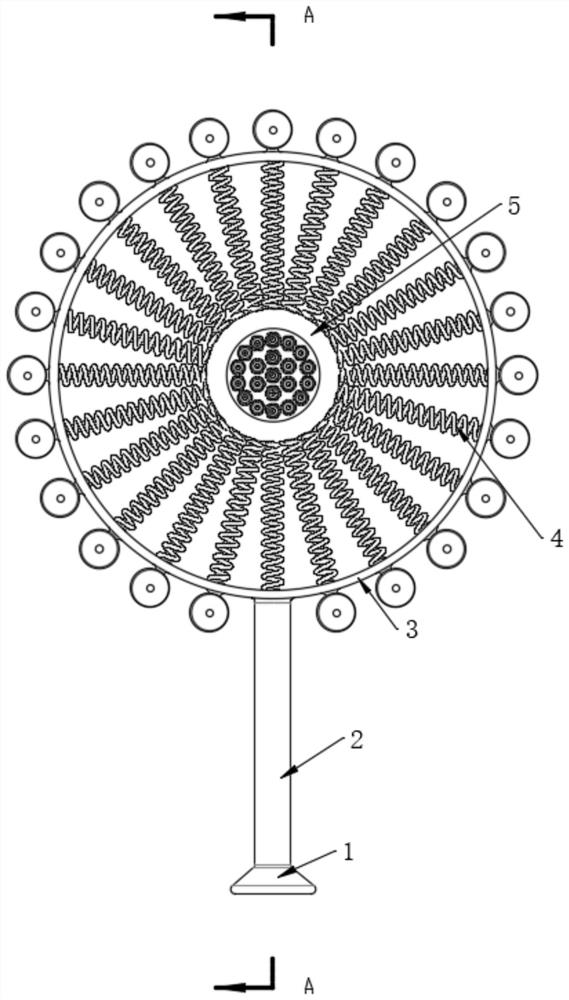

[0037] like Figure 1-6 As shown, a carpet beater for processing dust through airflow includes a base 1, a support 2 and an annular support 3, the top of the base 1 is fixedly connected to the support 2, and the top of the support 2 is fixedly connected to the annular support 3 , the inner wall of the annular support 3 is fixedly connected with multiple sets of telescopic springs 4, and a beating mechanism 5 is arranged between the multiple telescopic springs 4;

[0038]The beating mechanism 5 includes a waist drum beating block 51 fixedly connected with a plurality of telescopic springs 4, the waist drum beating block 51 is hollow, and the front of the waist drum beating block 51 is provided with multiple groups of equidistantly arranged cushioning carpet beating mechanisms 52, the waist drum beating The back side of the block 51 is provided with a circle of airflow holes 53, and the surface of the airflow holes 53 is provided with a carpet airflow blowing mechanism 54. By se...

Embodiment 2

[0043] like Figure 1-6 As shown, on the basis of Embodiment 1, the cushioning carpet beating mechanism 52 includes six sets of elastic arc plates 521, the back of the elastic arc plates 521 are fixedly connected with the waist drum beating block 51, and the six sets of elastic arc plates 521 are fixedly connected with Rubber pressing block 522, the inner surface of rubber pressing block 522 is provided with two circles of ring-shaped protrusions 523, through the buffer type carpet slapping mechanism 52, through the waist drum slapping block 51 to knock the carpet, the elastic arc plate 521 at the front end can be made to pass through the elastic force. change, so that the rubber pressing block 522 is deformed by extrusion, and the contacted carpet surface can be pushed away, and the dust at the bottom of the carpet can be quickly removed under the action of beating, by setting a ring The bump 523 increases the frictional force, which can increase the frictional force on the s...

Embodiment 3

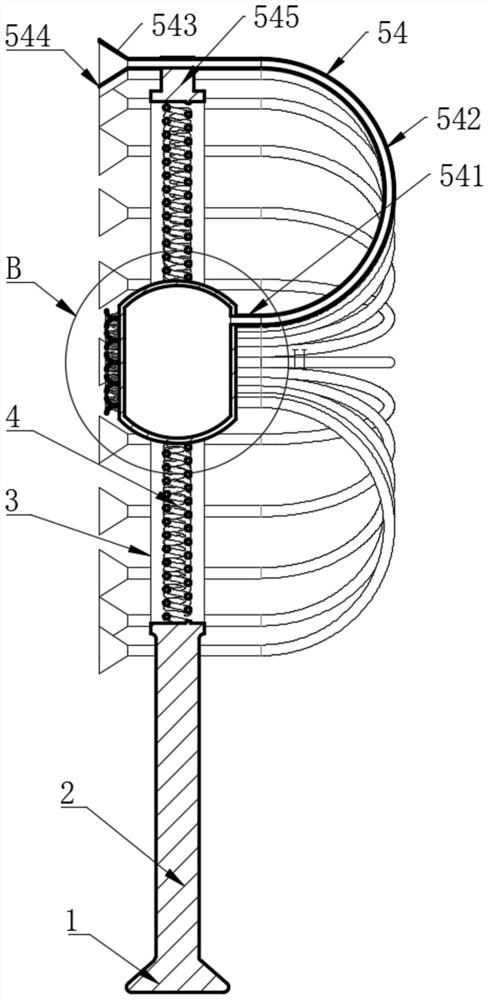

[0046] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the carpet airflow blowing mechanism 54 includes a straight nozzle 541 fixedly connected to the airflow hole 53, and the other end of the straight nozzle 541 is threadedly connected with an elbow passage 542, and The other end of the pipe passage 542 is threadedly connected with an air outlet trumpet pipe 543, and a support seat 545 is sleeved on the surface of the elbow passage 542. , after pressing, the flow of air flows into the elbow channel 542 through the straight pipe port 541 to change the channel direction, and the air outlet operation is performed through the air outlet horn tube 543, so that the air outlet horn tube 543 can clean the dust on the carpet, and the air outlet The setting of trumpet pipe 543 can enlarge blowing range, can allow the dust on the carpet in a larger range to be cleaned.

[0047] Further, the surface of the air outlet horn pipe 543 is provided with a viscose glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com