Bottle pushing mechanism, bottle packaging device and bottle pushing method

A bottle and bottle push rod technology, which is applied in the direction of packaging bottles, packaging, transportation and packaging, etc., can solve the problems of bottle misalignment, increase compactness and stability, increase anti-extrusion, facilitate transportation and The effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It can be seen from the background art that the bottle pushing rods used in the current bottle packaging devices cannot realize the misalignment of the bottles.

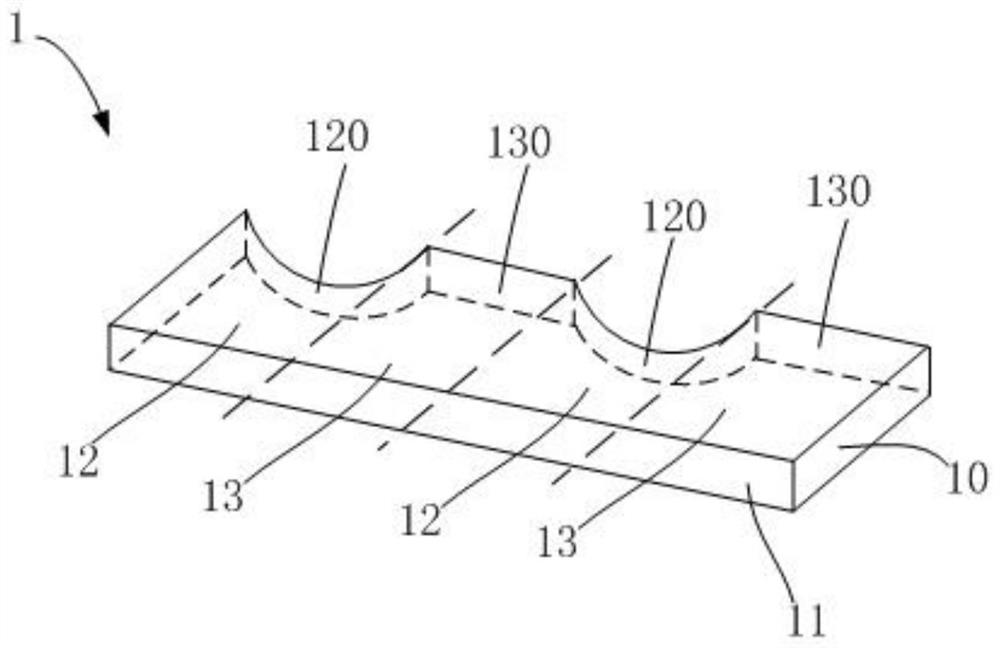

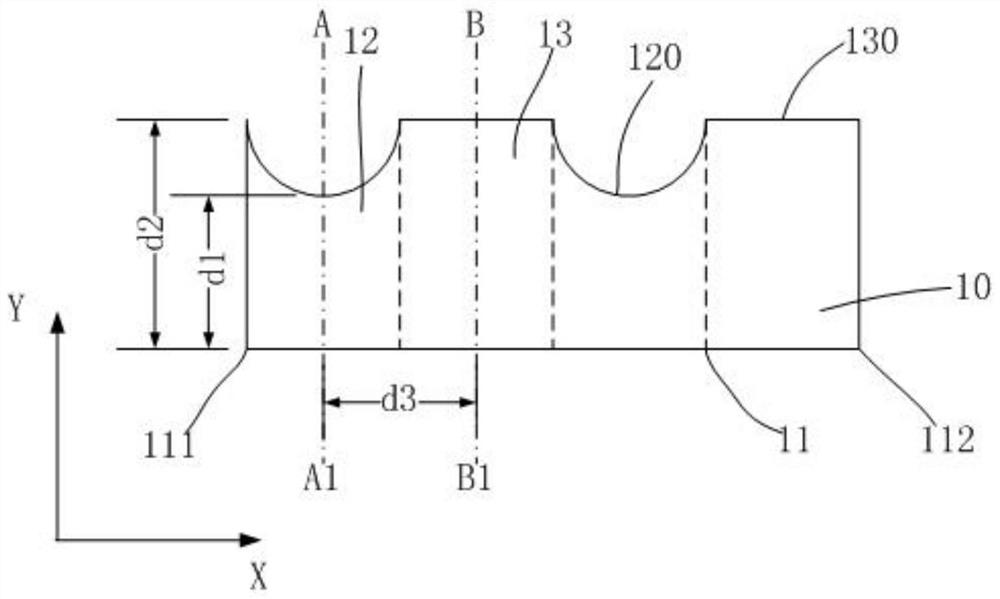

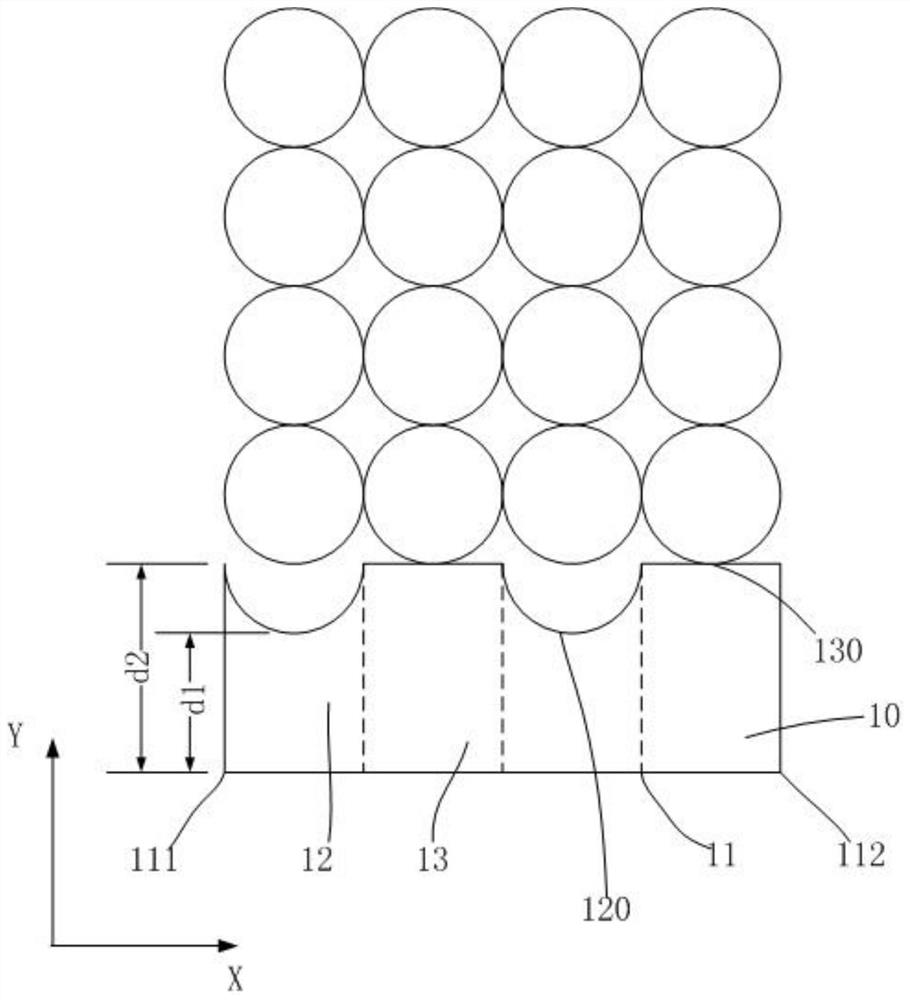

[0029] In order to solve the above-mentioned technical problems, an embodiment of the present invention provides a bottle pushing mechanism and a bottle packaging device, wherein the bottle pushing mechanism includes a bottle pushing part, and the bottle pushing part includes: a second bottle parallel to the length direction of the bottle pushing part An end face; and a first push area and a second push area arranged at intervals along the length direction of the push bottle part, the first push area includes a first push surface opposite to the first end face, and the second push The zone includes a second thrust surface opposite the first end surface, the second thrust surface having a maximum distance from the first end surface that is greater than a minimum distance from the first thrust surface to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com