Induction type rotor and switched reluctance motor

A switched reluctance motor, inductive technology, applied in the direction of magnetic circuit, electric components, electrical components, etc., can solve the problems of reduced magnetic energy utilization, reverse torque generation, output torque reduction, etc., to achieve excellent motor performance, The effect of strong starting ability, increasing output torque and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

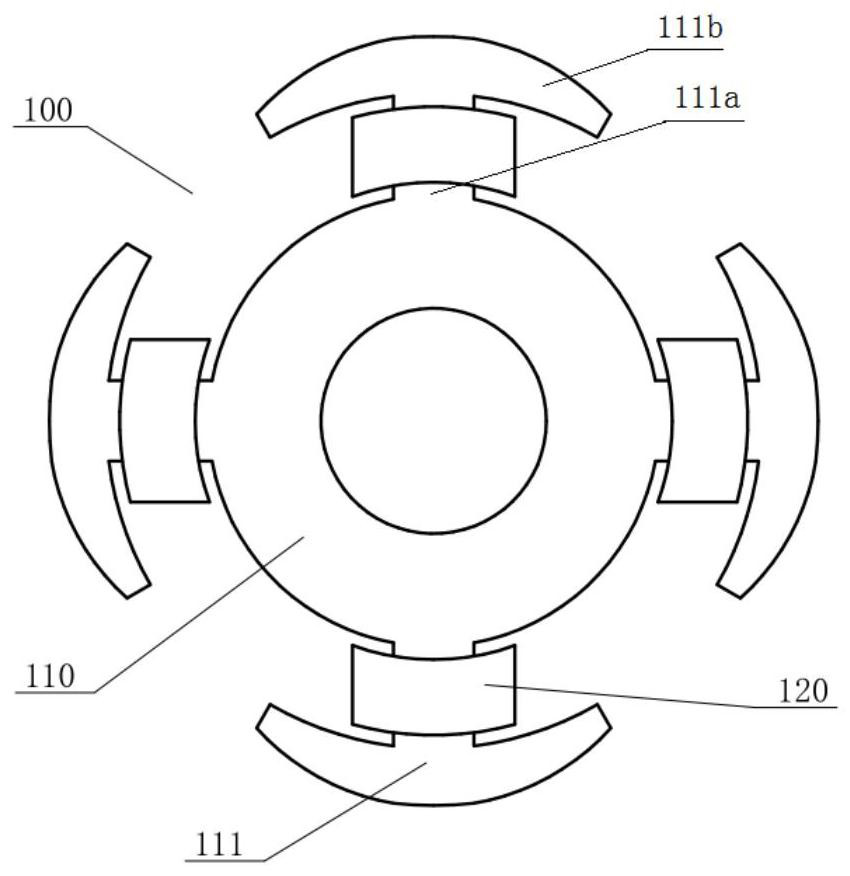

[0029] Figure 1-2What is shown is a structural schematic diagram of the induction rotor of the present invention. The induction rotor 100 includes a rotor core 110 and a conductive ring 120, the rotor core 110 is provided with a salient pole 111, the salient pole 111 is provided with a pole body 111a, and the conductive ring 120 is provided on the rotor 100 by surrounding the pole body 111a of the salient pole 111 superior. The salient poles 111 of the rotor core 110 are also provided with pole wings 111b, which are respectively connected to the left and right sides of the radially outer end of the pole body 111a. The pole wings 111b extend to the outside away from the pole body 111a, and The distance between the radially outer surface of the pole wing 111b and the center of the rotor core 110 in the extending direction changes gradually.

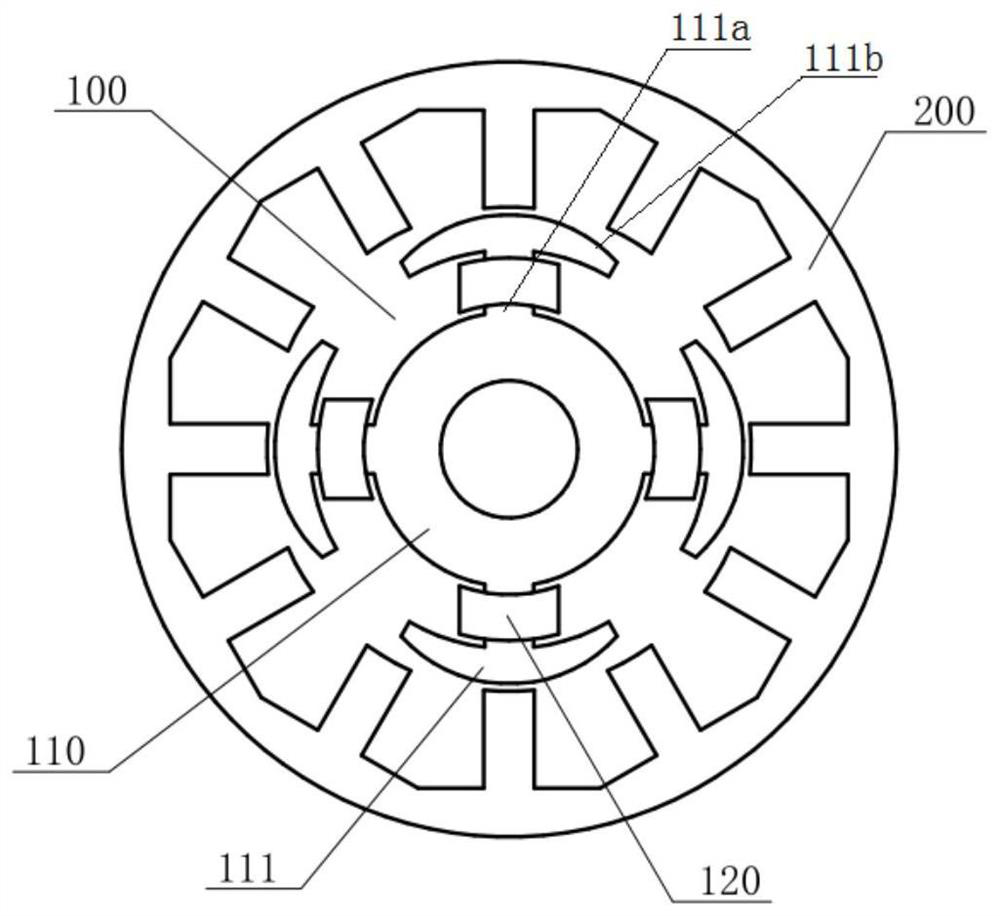

[0030] image 3 The shown switched reluctance motor applies the induction rotor 100 of this embodiment. The number of poles of the sta...

Embodiment 2

[0032] Figure 4 What is shown is another structural schematic diagram of the induction rotor of the present invention. The induction rotor 100 includes a rotor core 110 and a conductive ring 120, the rotor core 110 is provided with a salient pole 111, the salient pole 111 is provided with a pole body 111a, and the conductive ring 120 is provided on the rotor 100 by surrounding the pole body 111a of the salient pole 111 superior. The salient pole 111 of the rotor core 110 is also provided with a pole wing 111b, and the left and right sides of the radially outer end of the pole body 111a are respectively connected to the pole wing 111b, and the pole wing 111b and the pole body 111a form a pole body 111a high pole. The wing 111b is low and stepped, and the pole wing 111b extends to the outside away from the pole body 111a. The distance between the center of the rotor core 110 decreases in steps; the number of steps on the left and right sides of the pole body 111a is four resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com