Separated cable bridge for building installation

A cable tray, separate technology, applied in the direction of electrical components, etc., can solve the problems of difficult cable, take out, maintenance, etc., and achieve the effect of simple use, good maintenance effect, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

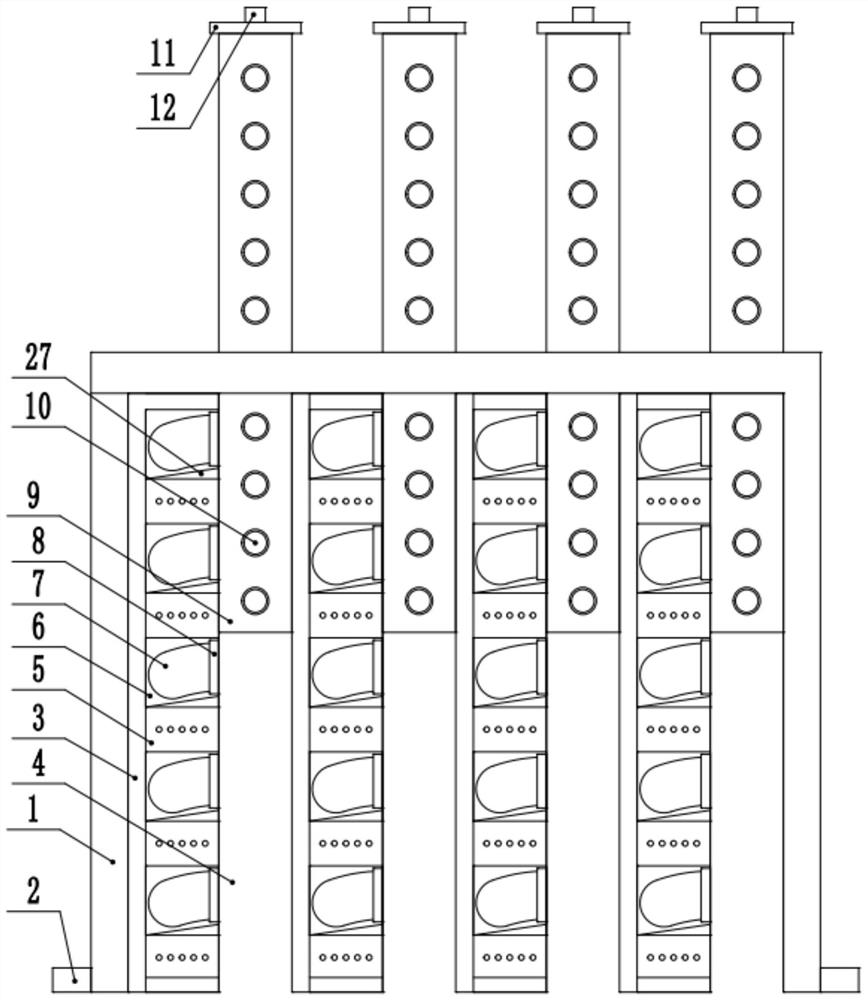

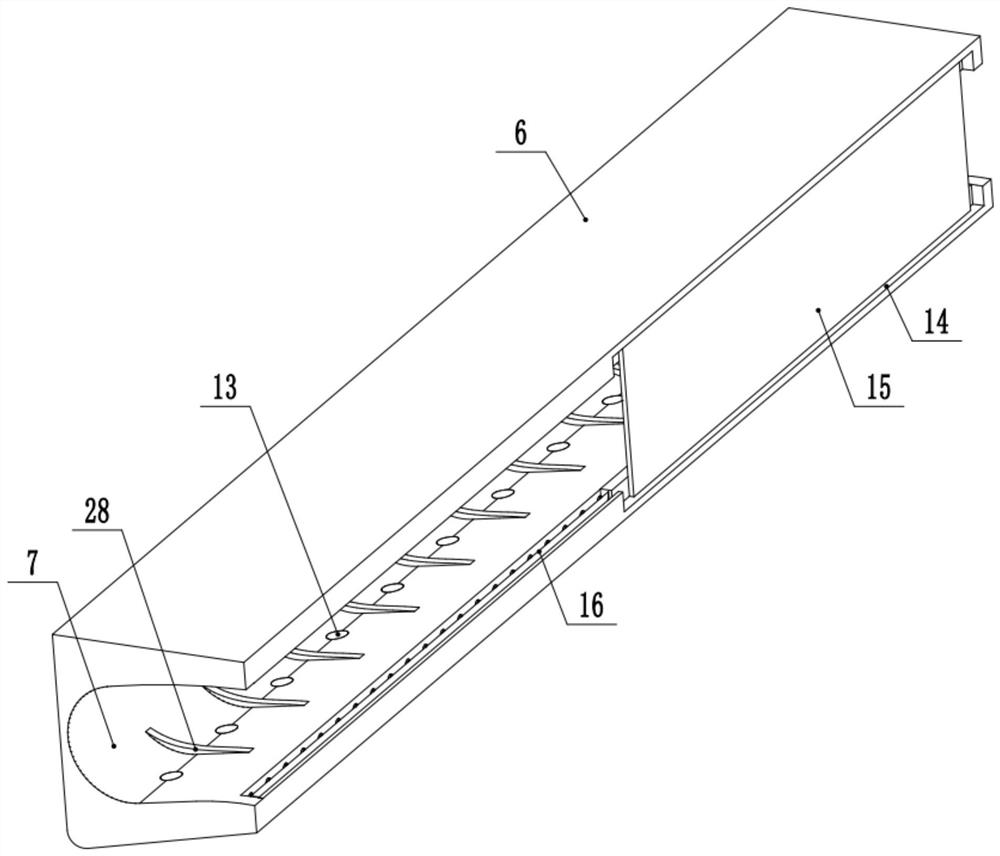

[0025] see Figure 1-5 , a detached cable bridge for building installation, comprising a bridge body 1, both sides of the bottom of the bridge body 1 are fixedly connected with legs 2, the bottom of the bridge body 1 is open, and the interior of the bridge body 1 is fixedly connected to a plurality of inner The mounting frame 3 is provided with a vertical channel 4 between every two adjacent internal mounting frames 3, and a plurality of fixed covers 5 are fixedly connected in the internal mounting frame 3, and a cable placement seat is placed on the top of each fixed cover 5 6. There is a cable placement groove 7 in the cable placement seat 6, and a limit blocking device 8 is provided on the side of the cable placement seat 6 close to the vertical passage 4. The cable placement groove 7 communicates with the vertical passage 4, and the vertical passage 4 A discharge cover 9 is provided, the discharge cover 9 penetrates the top end of the bridge body 1, and the end of the disc...

Embodiment 2

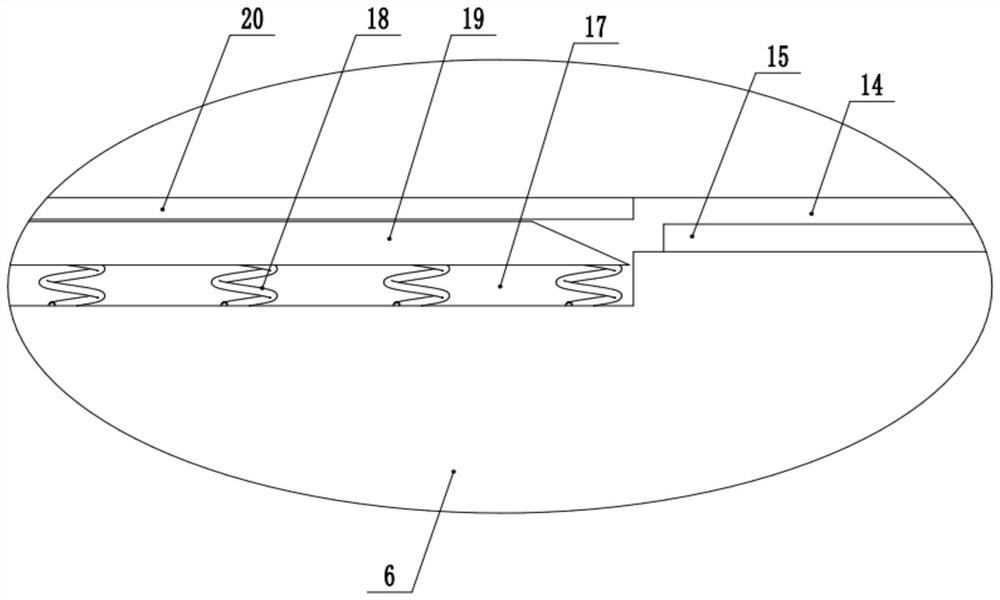

[0031] see Figure 1-5 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the bottom end of the cable placement seat 6 is provided with a plurality of first bottom grooves 13, and the top end of the fixed cover 5 is provided with a plurality of first bottom grooves 13. The first through hole 21 corresponding to the groove 13, the two ends of the fixed cover 5 are provided with a plurality of second through holes 22, and the lower part of the side of the fixed cover 5 close to the vertical channel 4 is provided with a side groove 23, the first through hole 21 , the second through hole 22 and the side groove 23 are all in communication with the inside of the fixed cover 5 .

[0032] The bottom of the cable placement groove 7 is fixed with a plurality of protruding ribs 28 , and the plurality of protruding ribs 28 are spaced apart from the plurality of first bottom grooves 13 . The protruding ribs 28 are used to separate the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com