Reliability analysis method for hydraulic multi-way valve

An analysis method and multi-way valve technology, applied in the field of hydraulic multi-way valve reliability analysis, can solve the problems of high cost, long time consumption, inaccurate analysis and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

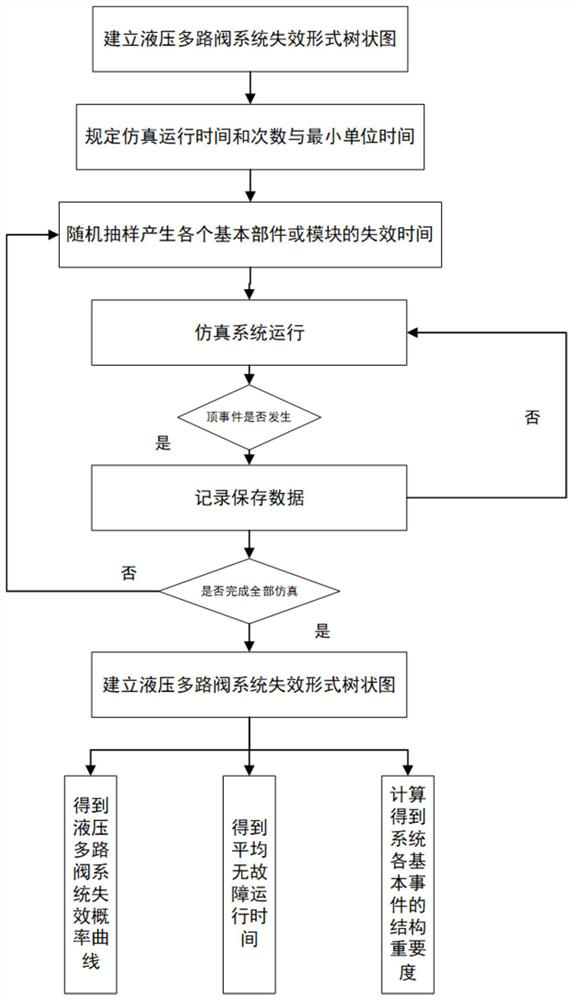

[0075] The reliability analysis method of the hydraulic multi-way valve should include the following steps:

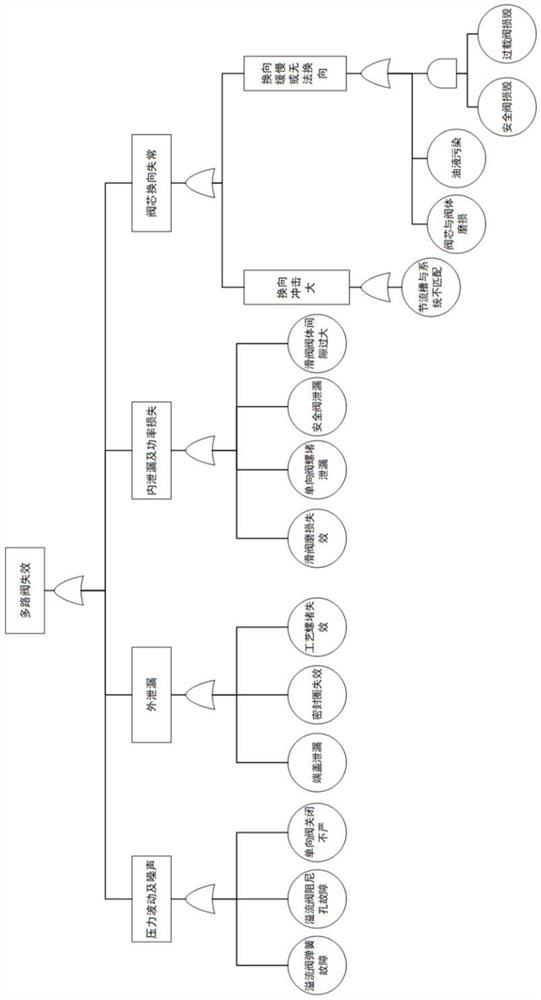

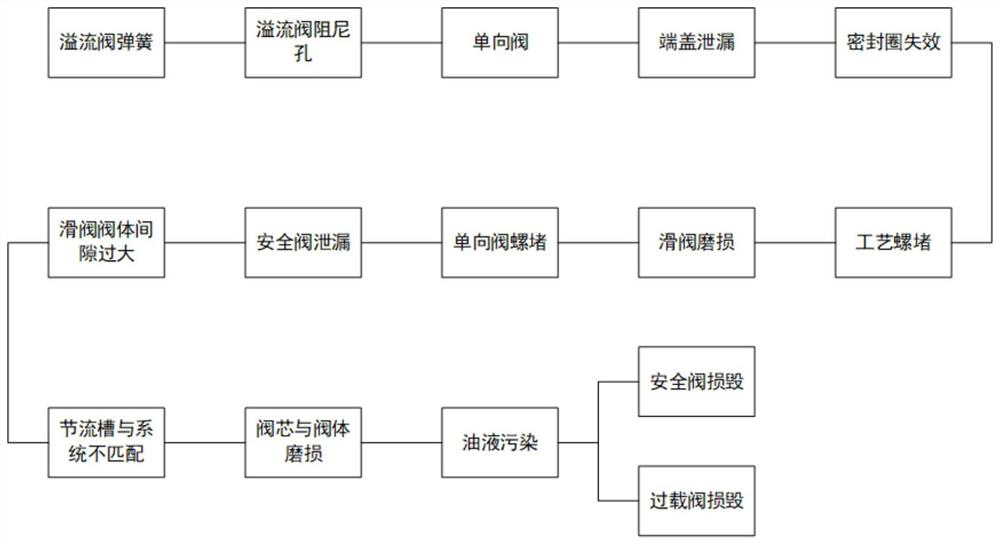

[0076] In step S1, a dendrogram is established for typical failure modes of the hydraulic multi-way valve. Such as figure 1 shown. The top event is T: the multi-way valve fails. The intermediate events are: Y1, Y2, Y3, Y4, Y5, Y6. The basic events are: X1, X2, X3, X4, X5, X6, X7, X8, X9, X10, X11, X12, X13, X14, X15. The failure mode tree diagram of the hydraulic multi-way valve described in the present invention covers typical multi-way valve failure modes, and from the four failure modes that directly lead to the failure of the multi-way valve, the causes are traced down layer by layer, and fifteen failure modes are obtained. Basic events for multiway valve failure. The basic event of the failure mode describes a certain failure form of one or some components, which is convenient for searching the failure rate corresponding to the basic event later. Considering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com