A road construction method for in-situ cold regeneration of asphalt pavement

A technology for asphalt pavement and road construction, which is applied to roads, roads, and on-site coagulation pavements, etc., can solve the problems of unfavorable regeneration structure layer durability, unstable regeneration layer quality, mixture deviation from design, etc. The effect of construction period, fast construction, and less loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

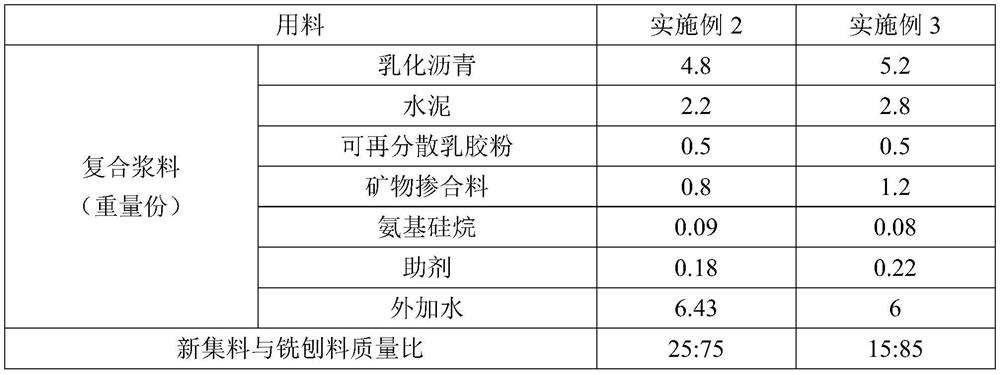

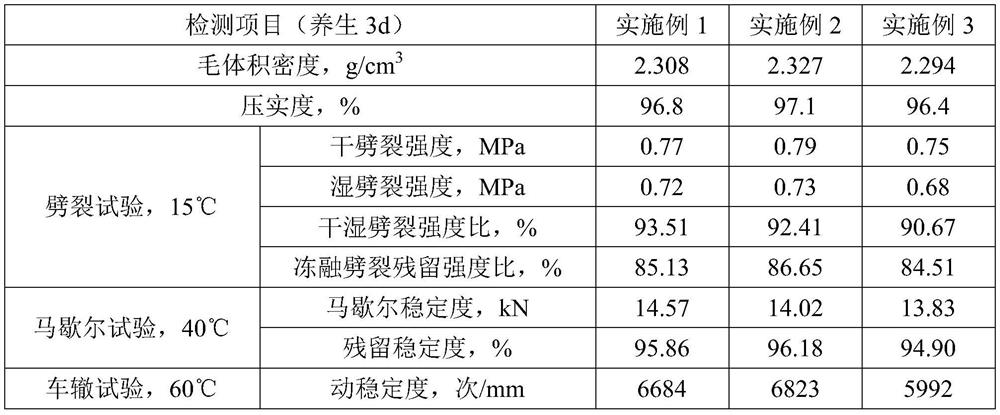

[0033] Taking a certain asphalt pavement renovation project as an example, the road construction method for in-situ cold regeneration of asphalt pavement according to the present invention will be further described. The structural layer of the old asphalt pavement is: 10cm asphalt surface layer + 20cm cement stabilized macadam base + 20cm graded macadam subbase; the pavement regeneration plan is: 10cm asphalt surface + 14cm emulsified asphalt cold recycled upper base + 20cm cement stabilized macadam Base + 20cm graded crushed stone subbase; design milling depth 10cm, that is, the old asphalt surface layer will be regenerated as the upper base layer, and then the asphalt surface layer will be paved again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com