A welding process platform with its own scribing device

A scribing device and welding process technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of high labor intensity of operators, poor splicing accuracy, and finished product calibration, so as to achieve firm and reliable splicing and ensure welding. The effect of precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

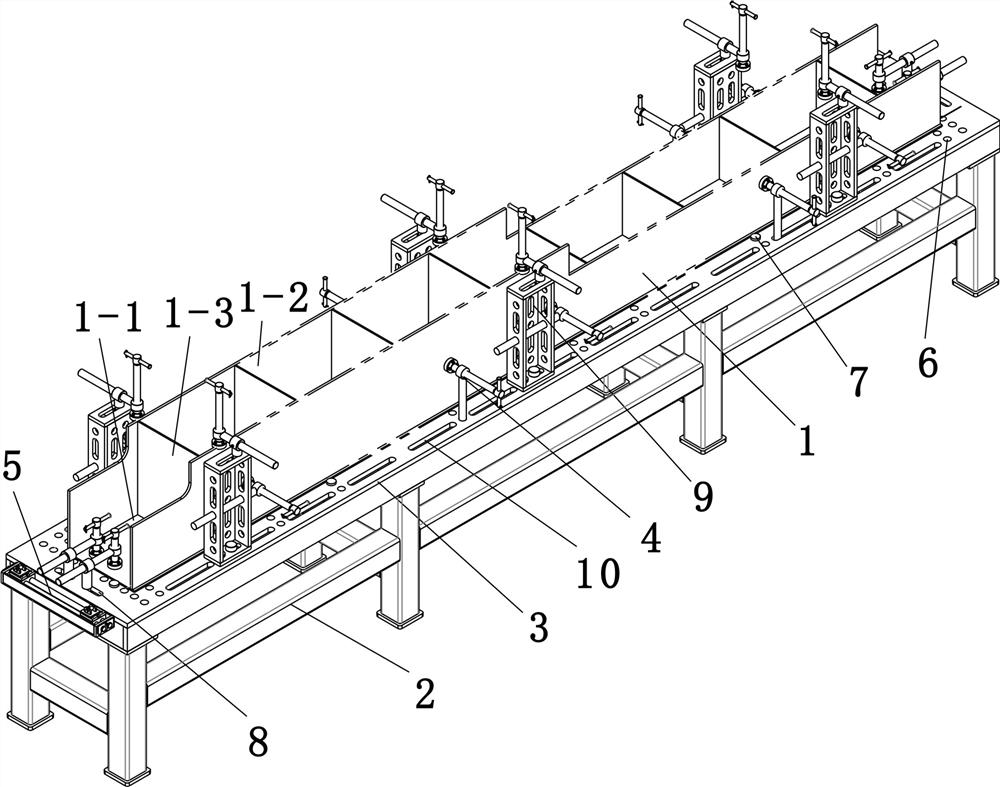

[0030] combined with Figures 1 to 4 , a welding process platform with its own scribing device, including a box girder 1 formed by correspondingly splicing a cover plate 1-1, a web plate 1-2 and a rib plate 1-3, and also includes a frame body 2 and a platform plate 3 , a pressing device 4 and a laser-assisted positioning device 5; the cover plate 1-1 is provided with a plurality of vertical rib plates 1-3 corresponding to the cover plate 1-1 at intervals along the length direction of the cover plate 1-1. Both sides of the plate surface of the plate 1-1 are provided with a vertical web 1-2 corresponding to the cover plate 1-1, and the rib 1-3 is in vertical contact with the web 1-2; the top of the frame body 2 is provided with There is a platform plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com