Ore particle screening device

A screening device and particle technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of the operator inhaling into the lungs, blocking the screening mesh, and shaking up large dust, so as to improve the efficiency , to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

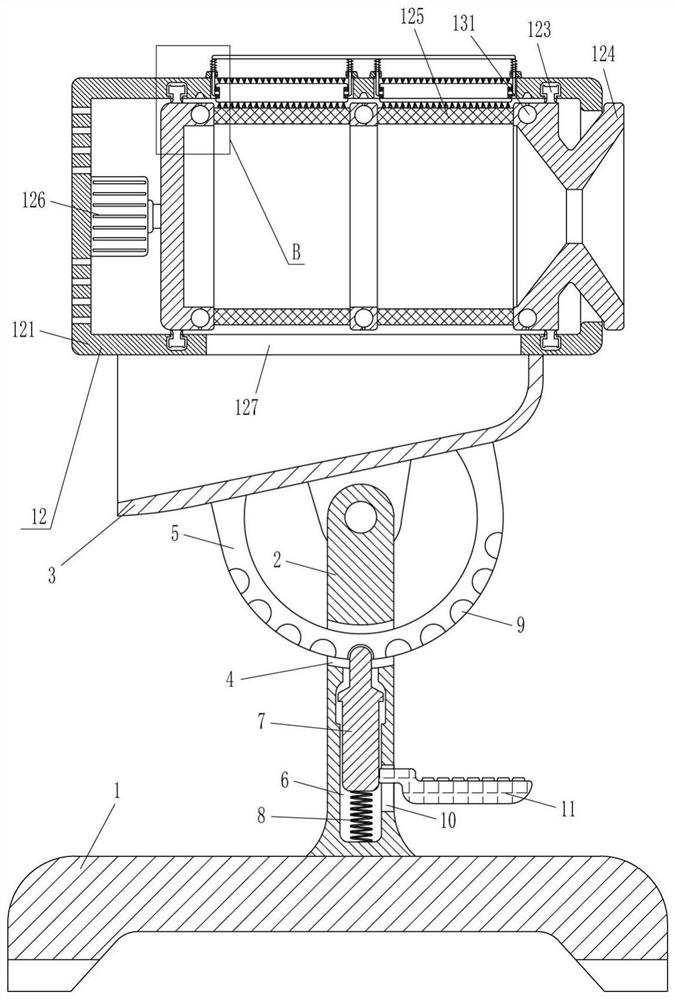

[0020] A screening device for ore particles, such as figure 1 As shown, it includes a base 1, a support rod 2, a discharge hopper 3, an arc rod 5, a clamp rod 7, a first spring 8, a pedal 11 and a screening device 12, and a support rod 2 is installed in the middle of the top of the base 1, and the base 1 It is connected with the support pole 2 by welding, the top of the support pole 2 is hingedly connected with a discharge hopper 3, the middle part of the support pole 2 has a first sliding hole 4, and the middle of the outer bottom of the discharge hopper 3 is equipped with an arc-shaped rod 5 , the arc rod 5 passes through the first slide hole 4, and the bottom of the pole 2 is vertically provided with a second slide hole 6, the second slide hole 6 intersects with the first slide hole 4, and the second slide hole 6 is provided with a slide type There is a clamping rod 7, a first spring 8 is connected between the bottom end of the clamping rod 7 and the second sliding hole 6, ...

Embodiment 2

[0022] A screening device for ore particles, such as figure 1 As shown, it includes a base 1, a support rod 2, a discharge hopper 3, an arc rod 5, a clamp rod 7, a first spring 8, a pedal 11 and a screening device 12, and a support rod 2 is installed in the middle of the top of the base 1, and the support rod 2. A discharge hopper 3 is installed on the top through a hinged connection. A first slide hole 4 is opened in the middle of the support rod 2. An arc rod 5 is installed in the middle of the outer bottom of the discharge hopper 3. The arc rod 5 passes through the first slide hole 4. The bottom of the pole 2 is vertically provided with a second sliding hole 6, the second sliding hole 6 intersects with the first sliding hole 4, and the sliding type in the second sliding hole 6 is provided with a clamping rod 7, and the bottom end of the clamping rod 7 is connected to the second sliding hole. A first spring 8 is connected between the sliding holes 6, and a plurality of groov...

Embodiment 3

[0025] A screening device for ore particles, such as Figure 1-3As shown, it includes a base 1, a support rod 2, a discharge hopper 3, an arc rod 5, a clamp rod 7, a first spring 8, a pedal 11 and a screening device 12, and a support rod 2 is installed in the middle of the top of the base 1, and the support rod 2. A discharge hopper 3 is installed on the top through a hinged connection. A first slide hole 4 is opened in the middle of the support rod 2. An arc rod 5 is installed in the middle of the outer bottom of the discharge hopper 3. The arc rod 5 passes through the first slide hole 4. The bottom of the pole 2 is vertically provided with a second sliding hole 6, the second sliding hole 6 intersects with the first sliding hole 4, and the sliding type in the second sliding hole 6 is provided with a clamping rod 7, and the bottom end of the clamping rod 7 is connected to the second sliding hole. A first spring 8 is connected between the sliding holes 6, and a plurality of gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com