Extrusion system for flow battery bipolar plate production and extrusion method thereof

A technology of flow battery and bipolar plate, which is applied in the parts of fuel cell, liquid injection device, injection device, etc., can solve the problems of poor use effect, affecting the internal resistance of the stack, contact internal resistance, etc., to improve the use of effect, improve sealing effect, ensure continuity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

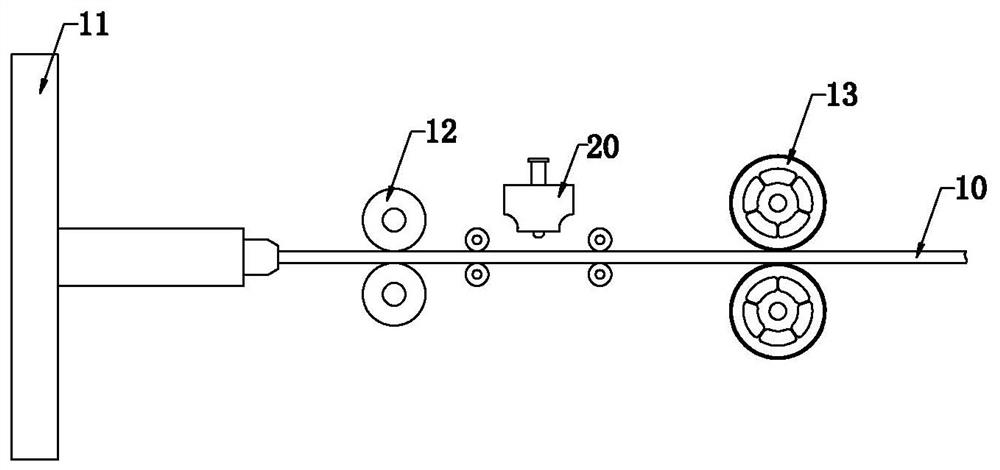

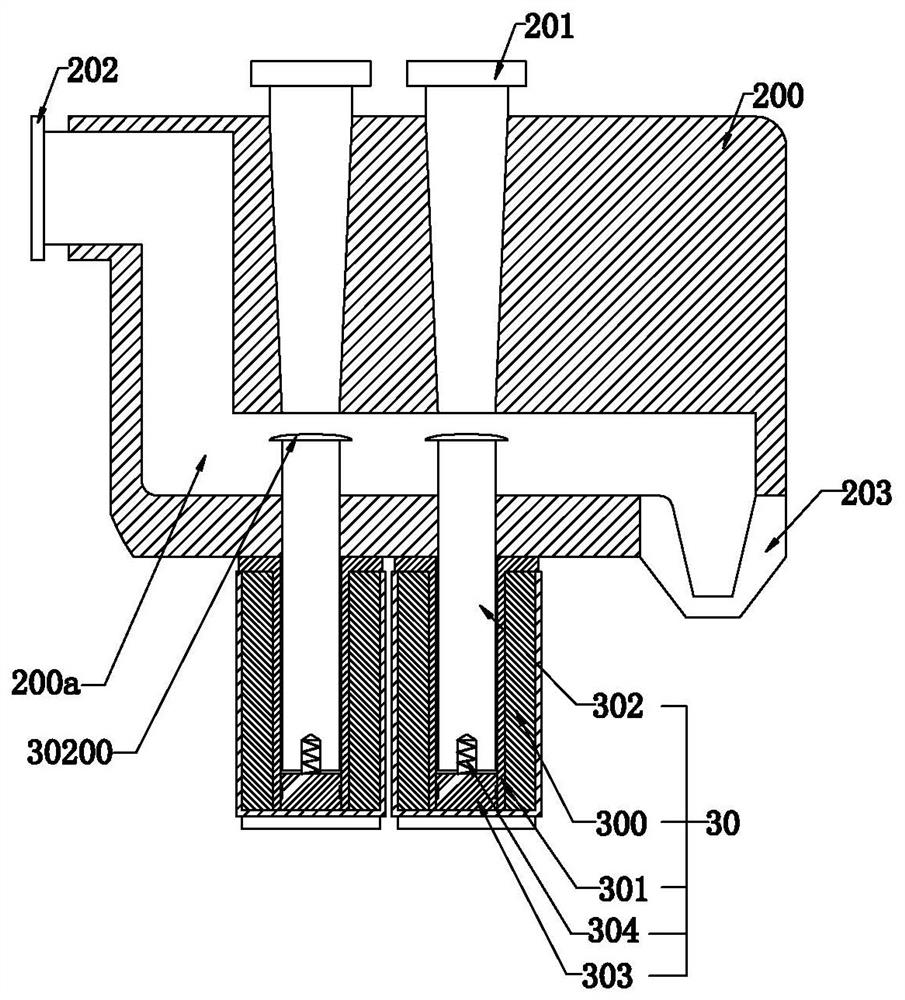

[0045] Such as Figure 1-Figure 3 As shown, the present invention discloses an extrusion system for the production of flow battery bipolar plates, including an extrusion die 11 arranged in sequence and used to pull a bipolar plate 10, a thermal insulation conveying roller 12, and a shaping roller 13. In the present invention In a specific embodiment, it includes a spraying module 20 that is arranged between the heat-retaining conveying roller 12 and the shaping roller 13 and is used for spraying additives on the bipolar plate 10; wherein, the spraying module 20 includes at least one with a gas input When spraying, the gas inlet enters the air and sprays out to the spraying end to form a conveying air flow, and each additive is added to each auxiliary input end, and is controlled by electromagnetic The module 30 controls the opening or closing of each auxiliary agent output port to carry out the proportioning of the auxiliary agent and add it into the spray body 200, and mix an...

Embodiment 2

[0066] Embodiment 2 is different from Embodiment 1 in that (it should be noted that in this embodiment, Q means intake air, and P means air outlet / or exhaust):

[0067] like Figure 4-Figure 6 As shown, in the specific embodiment of the present invention, each sprinkler body is provided with an anti-blocking opening 50 communicating with the conveying chamber 200a; it also includes several anti-blocking openings 50 that can be inserted into and used to clean the conveying chamber 200a. The anti-blocking module 60 of the cavity 200a; the anti-blocking module 60 includes a plurality of dredging rods 600 corresponding to each anti-blocking port 50 and moving through the cylinder control and a cleaning part 601 installed on the free end of the dredging rod 600; The cleaning part 601 includes a first cleaning part 6011 installed on one end of the dredging rod 600 and having a diameter of L1, and a second cleaning part 6012 installed on the side of the first cleaning part 6011 away ...

Embodiment 3

[0082] Embodiment 3 is different from Embodiment 1 in that it is worth noting that this embodiment is a modification of Embodiment 1, which cannot be shared with Embodiment 2, as follows:

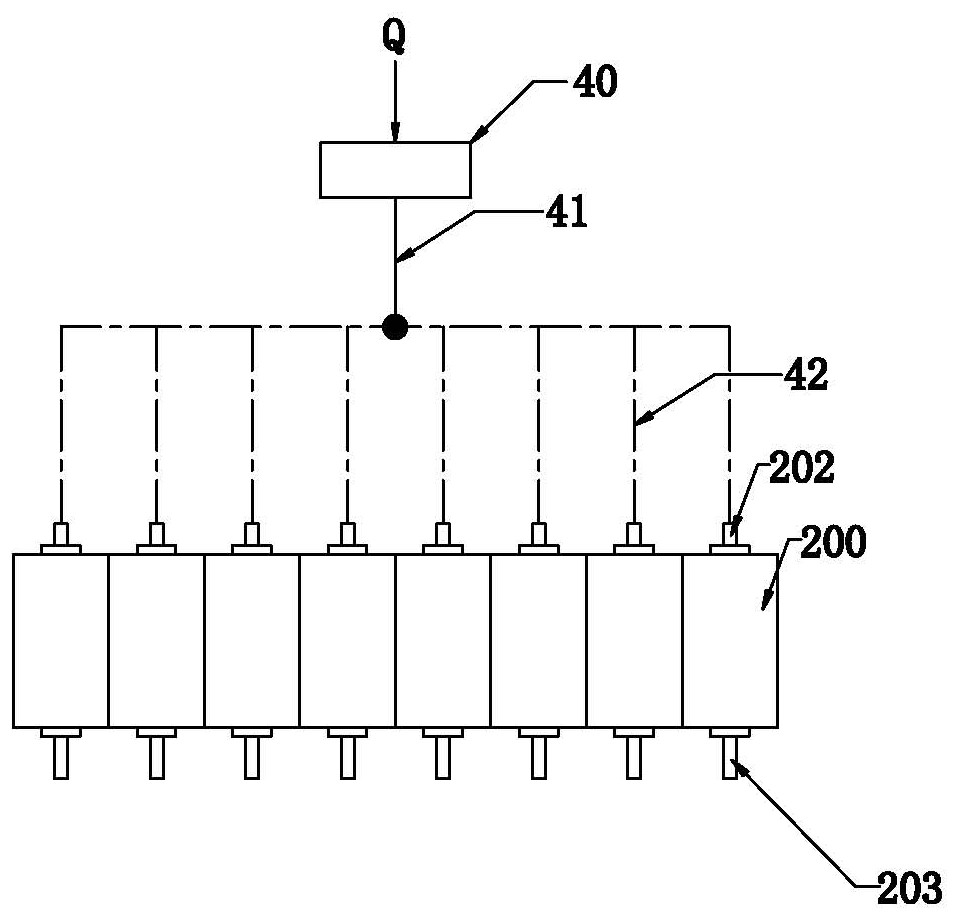

[0083] like Figure 7-Figure 9As shown, this embodiment discloses an extrusion system for the production of bipolar plates of a liquid flow battery, including an extrusion die 11 arranged in sequence and used to pull a bipolar plate 10, a thermal insulation conveying roller 12, and a shaping roller 13. In the present invention In a specific embodiment, it includes a spraying module 20 that is arranged between the heat-retaining conveying roller 12 and the shaping roller 13 and is used for spraying additives on the bipolar plate 10; wherein, the spraying module 20 includes at least one with a gas input One end, two auxiliary agent input ends, and one spraying body at the spraying end; when spraying, the gas input end enters the air and sprays out to the spraying end to form a conveying air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com