Electronic equipment digital production management system based on MBOM baseline

A technology of production management system and electronic equipment, which is applied in the field of digital manufacturing, can solve problems such as shortage, achieve the effects of easy management, realize product modular management, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

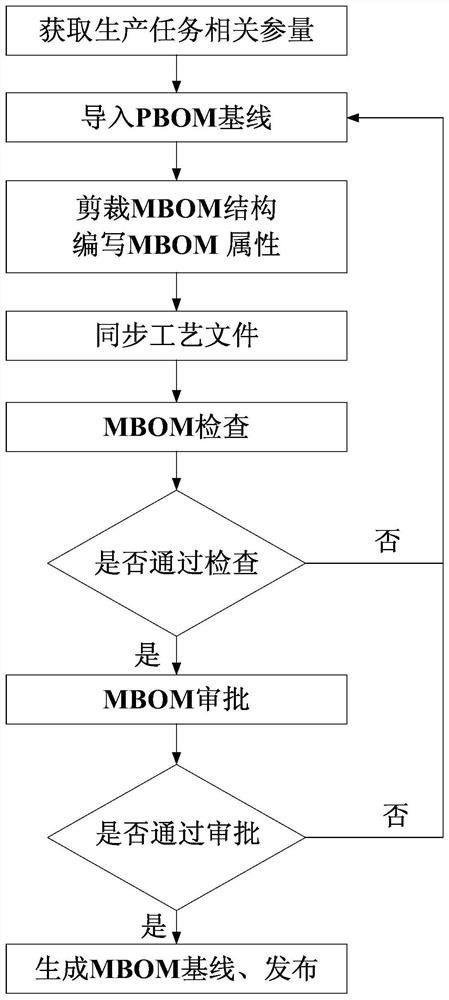

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] A digital production management system for electronic equipment based on MBOM baseline, including:

[0029] A receiving task module, used to receive the issued product production task instructions, and at the same time query and obtain the official production task of the product in the dynamic database;

[0030] A Bill of Materials (BOM) conversion module, used to convert PBOM (Process Bill of Materials) into MBOM (Manufacturing Bill of Materials);

[0031] An MBOM editing module, used for tailoring the MBOM structure and editing the MBOM attributes according to the production task;

[0032] A synchronous process document module, which is used to synchronize the process documents in the PBOM baseline, and perform flip calculations based on actual production quantities and established rules;

[0033] An MBOM baseline generation modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com