On-line nondestructive thickness measuring device for advanced-generation substrate glass

A thickness measurement and glass technology, applied in the field of high-generation substrate glass online non-destructive thickness measurement device, can solve the problems of reducing product yield, proportional increase, affecting the cleanliness of glass surface, etc., to reduce measurement difficulty, high accuracy, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

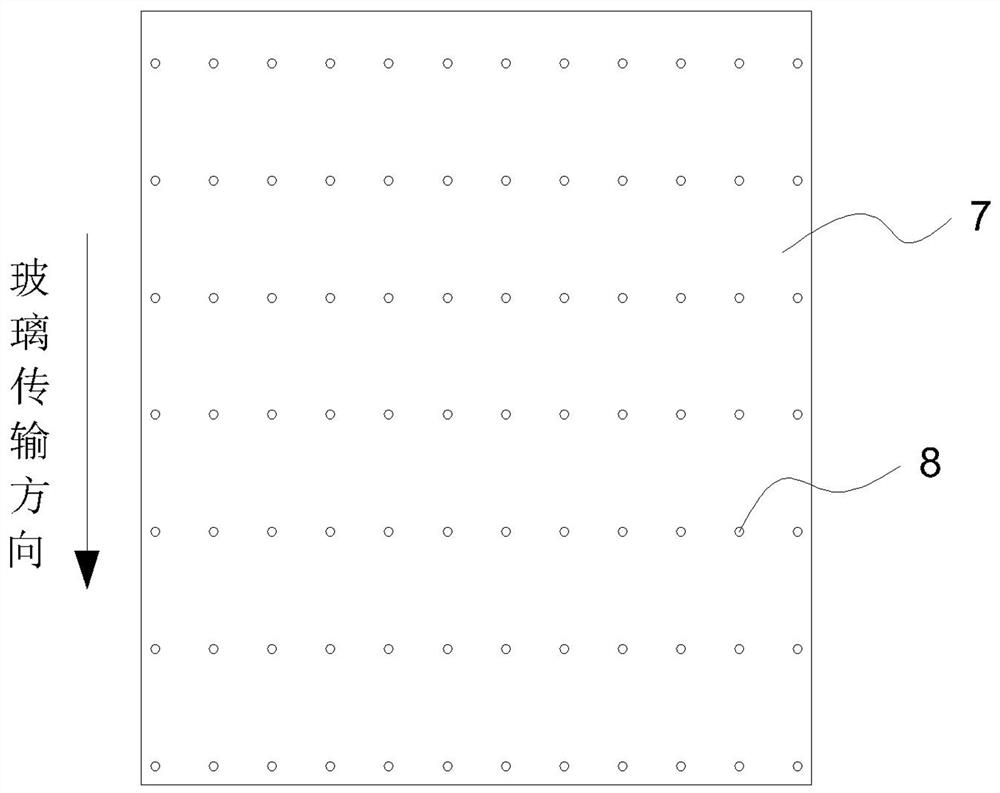

[0015] Such as figure 1 As shown, the present invention provides an online non-destructive thickness measurement device for high-generation substrate glass, which includes a mounting bracket 2 arranged above the glass transmission roller 1, the mounting bracket 2 is perpendicular to the transmission direction of the glass plate 7, and is arranged at intervals along the mounting bracket. There is a group of laser thickness gauges 3, and the probes 4 of the laser thickness gauges are arranged vertically downward; a total of twelve laser thickness gauges are used in this embodiment.

[0016] The measuring device also includes a laser thickness measurement control unit 5 and a host computer 6 connected by mutual communication, and each laser thickness measurement instrument is connected with the laser thickness measurement control unit 5 respectively.

[0017] combine figure 2 As shown, when the glass plate 7 is transported by the glass transport roller 1, the laser thickness me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com