Calcining device for ceramic structural part

A technology for calcination devices and structural parts, which is applied in the direction of furnace components, electric furnace heating, furnace types, etc., which can solve the problems of low calcination efficiency and achieve the effect of avoiding slow temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

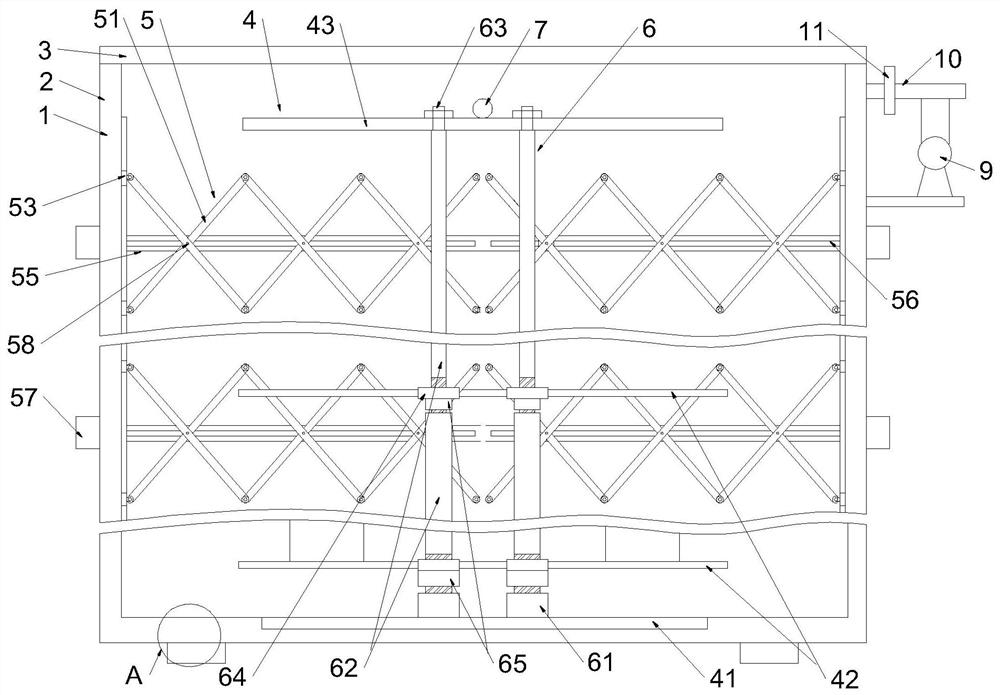

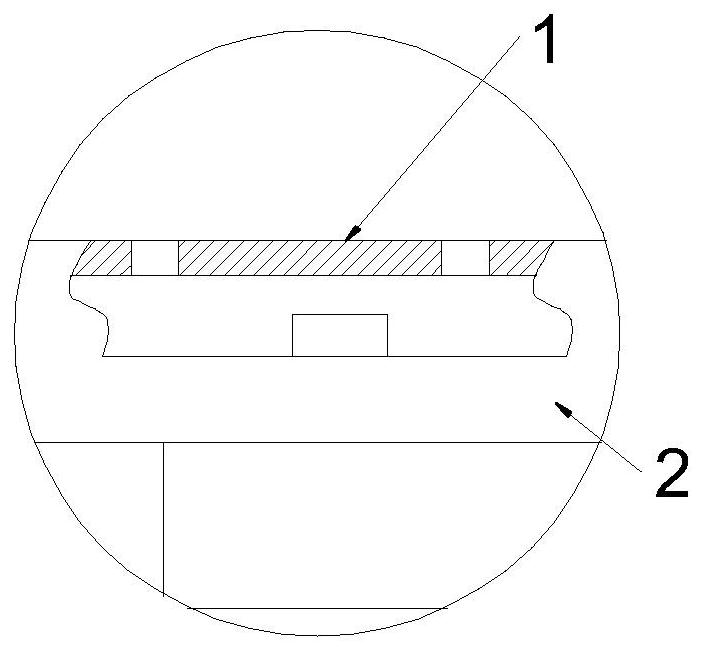

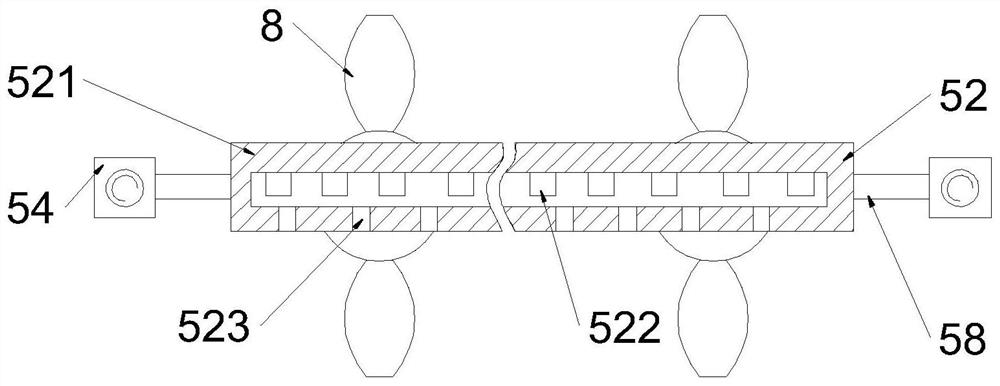

[0021] combine Figure 1 to Figure 4 The calcination device of a ceramic structural part shown in this embodiment includes a calcination furnace body 2 with a calcination layer 1 laid on the inner wall and a cover 3 sealed and closed on the top of the calcination furnace body 2, and also includes a shelf 4 and the level heating group 5, the shelf 4 includes positioning plates 41 distributed sequentially from bottom to top, at least two sets of shelf bodies 42 and hanging plate frames 43, the bottom of the calciner body 2 is provided with positioning plates 41 for positioning The positioning groove, and the positioning plate 41, the storage plate body 42 and the hanging plate frame 43 are fixedly connected by two sets of connecting column groups 6, and at least one group of lifting rings 7 is fixed on the top of the hanging plate frame 43; Between the two groups of storage board bodies 42 and between the storage board body 42 and the hanging plate frame 43, two sets of relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com