Test cable control device

A control device and testing cable technology, which can be used in measurement, wellbore/well components, earthwork drilling and production, etc., and can solve the problems of high labor intensity for testers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

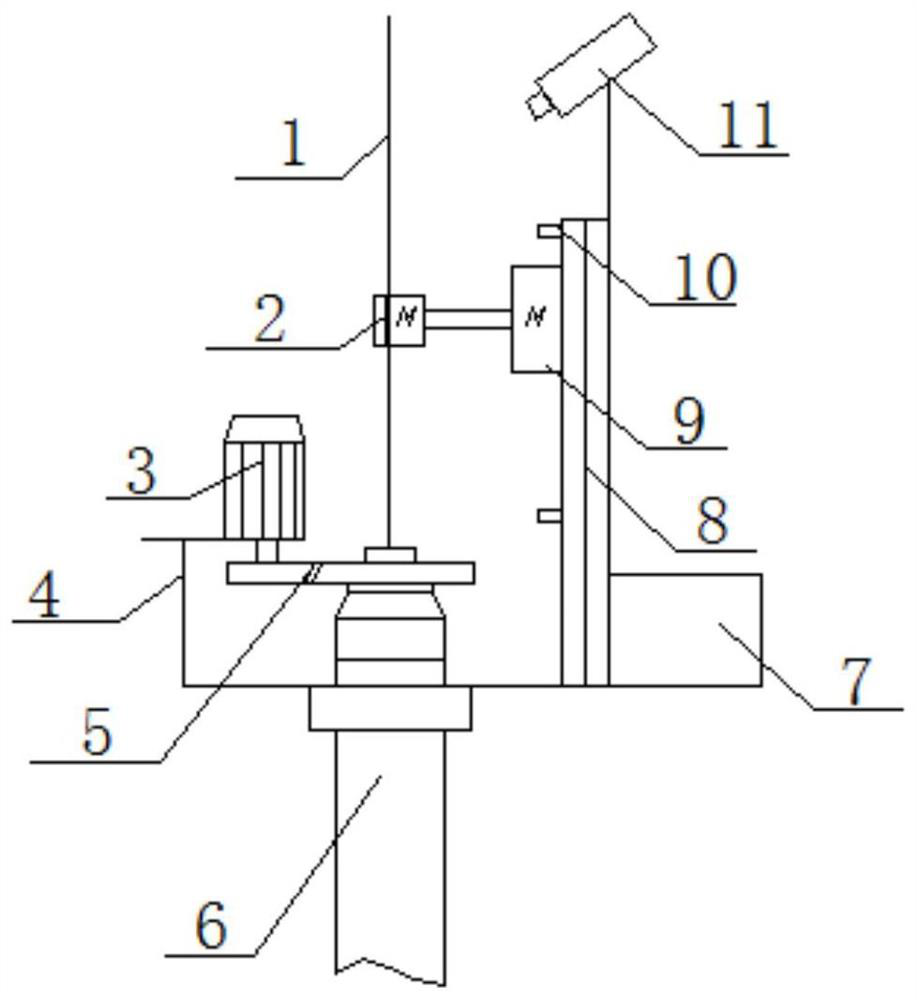

[0018] Such as Figure 1-2 As shown, a test cable control device includes a blowout preventer 6 installed on the base, and a pressure cap adjustment device is installed on the upper end of the blowout preventer 6 . The pressure cap adjustment device includes a pressure cap adjustment gear 5 connected to the blowout preventer 6, the pressure cap adjustment gear 5 is keyed to a second motor 3, and the second motor 3 is used to adjust and control precise torque, so The second motor 3 is installed on the base through an adjustable bracket 4 . The adjustable support 4 is a movable support, which ensures the ease of installation of the whole device.

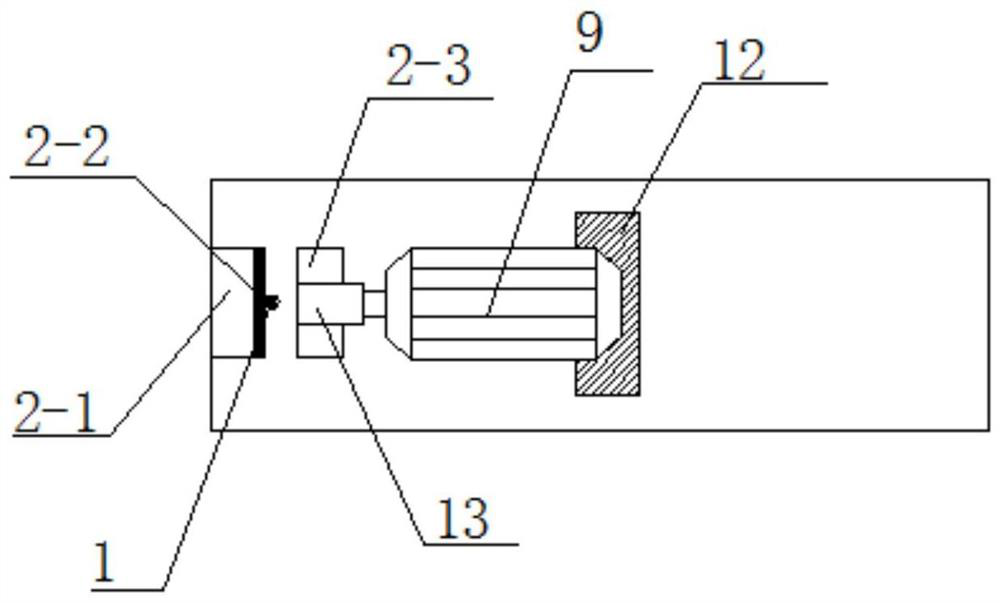

[0019] A cable 1 is installed on the upper end of the pressure cap adjustment device, and a cable clamping device 2 is installed on the cable 1, and the cable clamping device 2 is located above the pressure cap adjustment device. The cable clamping device 2 includes a clamping block 2-1 installed on one side of the cable 1, and a cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com