Roadbed construction method of highway reinforced concrete pavement

A reinforced concrete and construction method technology, applied in the direction of roads, roads, climate sustainability, etc., can solve problems such as road surface fracture, inconvenient road surface repair, and short service life of the roadbed, so as to reduce repair projects and facilitate maintenance and repair , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

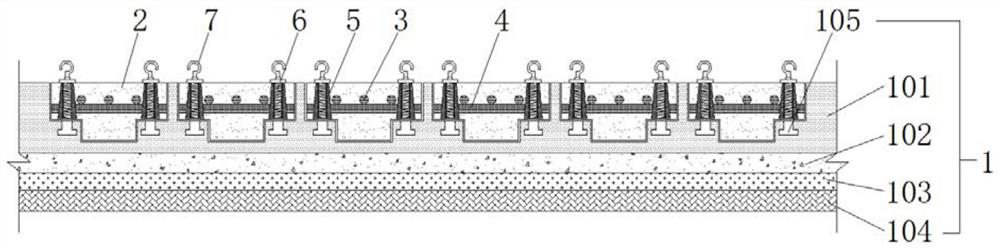

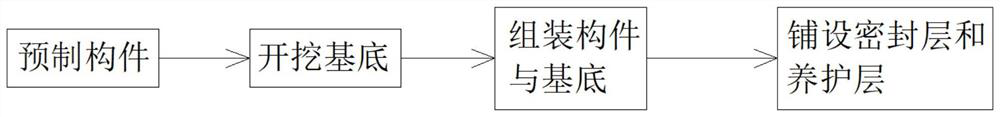

[0073] First arrange the longitudinal steel bars 3 and the horizontal steel bars 4 vertically and tie them securely, then put the whole of the longitudinal steel bars 3 and the horizontal steel bars 4 into the mold, and fix the fixing parts 5 at the designated positions, then pour concrete and wait for cooling to form Concrete block 2, and then install the stopper 6 in the interior of the fixture 5 by means of threaded connection, and lift up the mold by hooking the hook 7 above the stopper 6; it is made by formwork pouring cement concrete layer 101, and make the upper surface of the cement concrete layer 101 have a concave-convex structure, place the concrete block 2 on the inside of the cement concrete layer 101, then remove the stopper 6, and fix it by pouring concrete. The inside of part 5 and the notch 105 are filled, and the reliability of the connection between the concrete block 2 and the base 1 is enhanced. Finally, the sealing layer 8 is laid on the upper surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com