A coating device with reciprocating movement and synchronous horizontal rotation

A technology of horizontal rotation and reciprocating movement, which is applied to cells, electrolytic components, electrolytic processes, etc., and can solve problems such as excessive motor consumption, motor corrosion, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

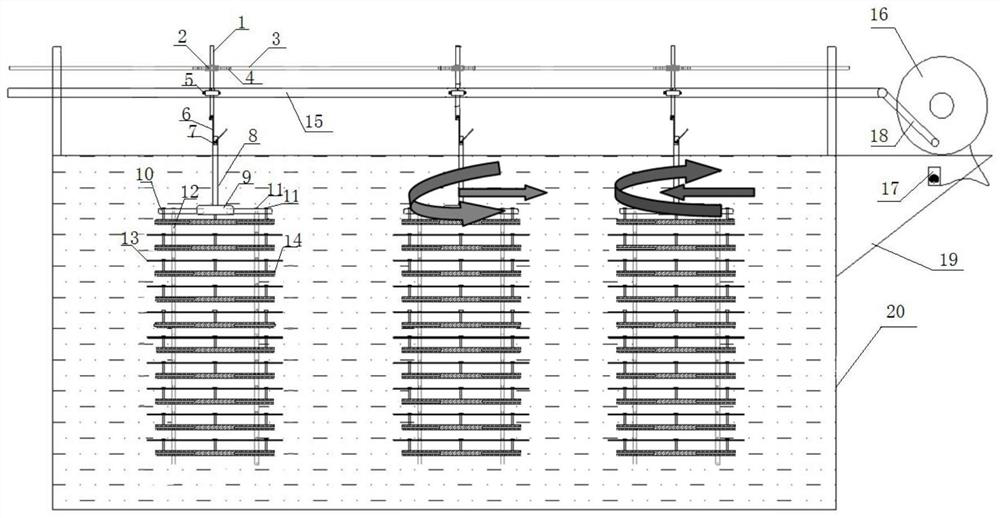

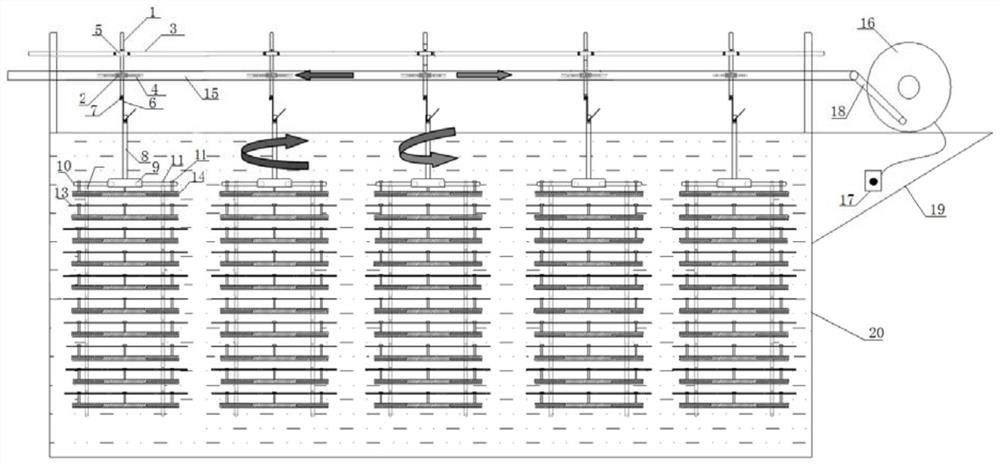

[0029] Such as figure 1 As shown, the present invention is a coating device that horizontally reciprocates while horizontally rotating, a mounting frame assembly, a horizontal rotating assembly and a horizontal reciprocating assembly;

[0030] The horizontal rotation assembly includes upper shaft 1, synchronous wheel 2, synchronous belt fixed rod 3 and synchronous belt 4; Mesh transmission connection; the lower end of the upper shaft 1 is suspended and connected to the installation frame assembly;

[0031] The horizontal reciprocating movement assembly includes a moving pole 15, a cathode moving motor 16 and a rocking bar 18; the upper shaft 1 is connected to the moving pole 15 through a bearing 5, and the motor support 19 is provided with a cathode moving motor 16, and the cathode moving motor 16 passes through the rocker. The rod 18 is connected to the cathode rod 15 for reciprocating drive, and the cathode moving motor 16 is provided with a frequency regulator 17;

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com