A timing control material receiving system and method

A timing control and time setting technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of poor control accuracy, achieve uniform load, easy flow control, and reduce weighing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

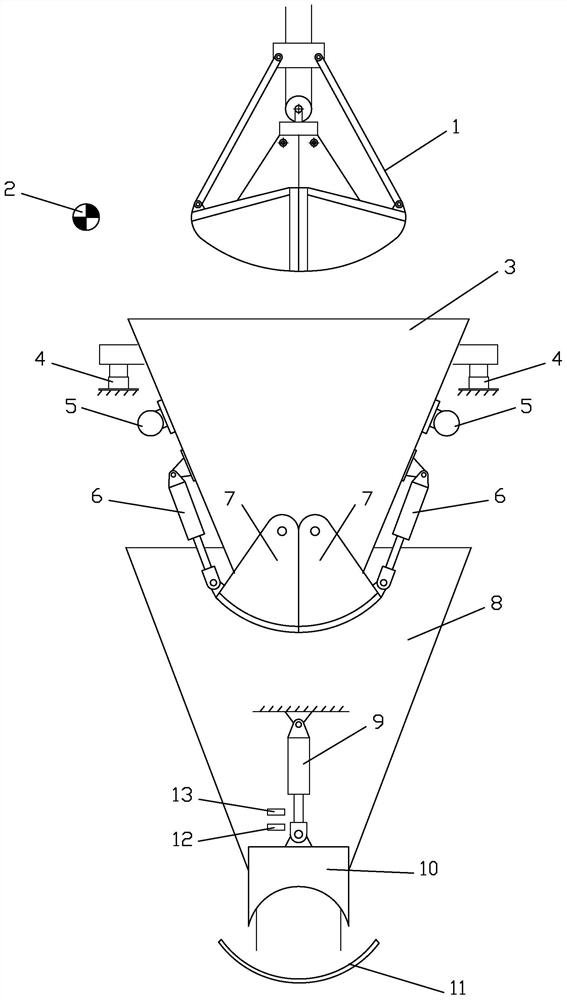

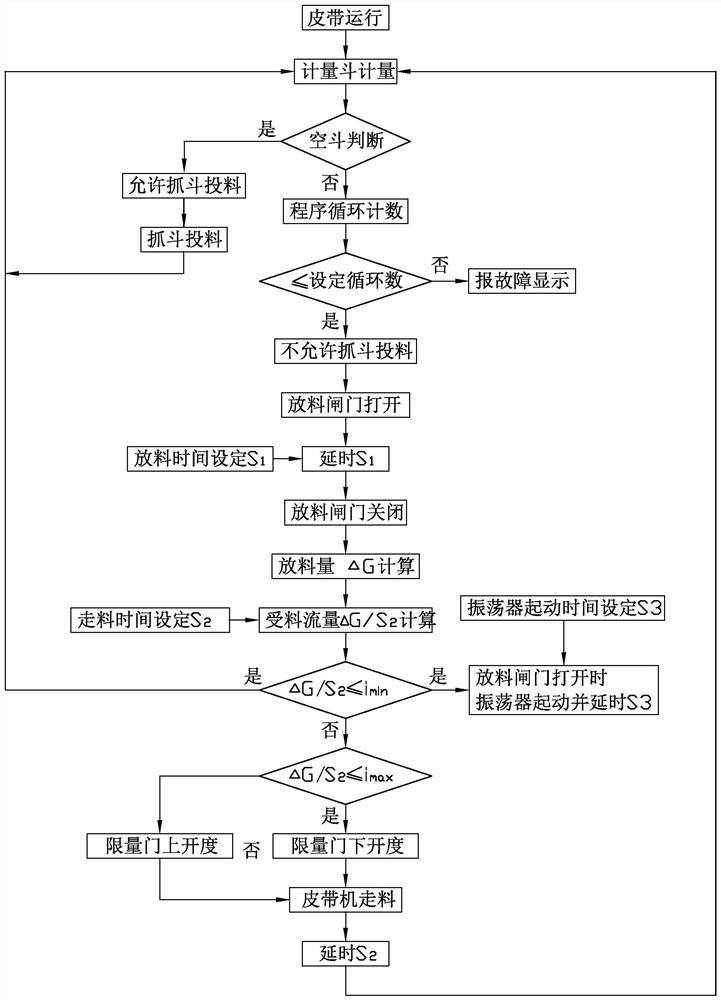

[0030] The first embodiment provides a figure 1 The timing-controlled material receiving system shown includes a grab bucket 1 and a weighing bucket 3 located below the outlet of the grab bucket 1. A buffer bin 8 is provided under the outlet of the weighing bin 3, and a belt is provided under the outlet of the buffer bin 8. machine 11; at least one weight sensor 4 is provided on the outside of the warehouse wall of the weighing bucket 3, and a gate 7 of a timing switch is provided at the outlet of the weighing bucket 3, and the gate 7 is arranged on the outside of the warehouse wall of the weighing bucket 3 The driving cylinder one 6 is driven; the bottom of the buffer bin 8 is provided with an upper limit switch 13 and a lower limit switch 12, and the outlet of the buffer bin 8 is provided with a limit door 10 driven by the driving cylinder two 9; the material receiving system It also includes a signal lamp 2 ; at least one oscillator 5 is provided outside the bin wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com