A parallel passive compliance device

A passive and flexible technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of complex branch structure, high economic cost, complicated structure, etc., and achieve the effect of simple branch structure, high economic benefit and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

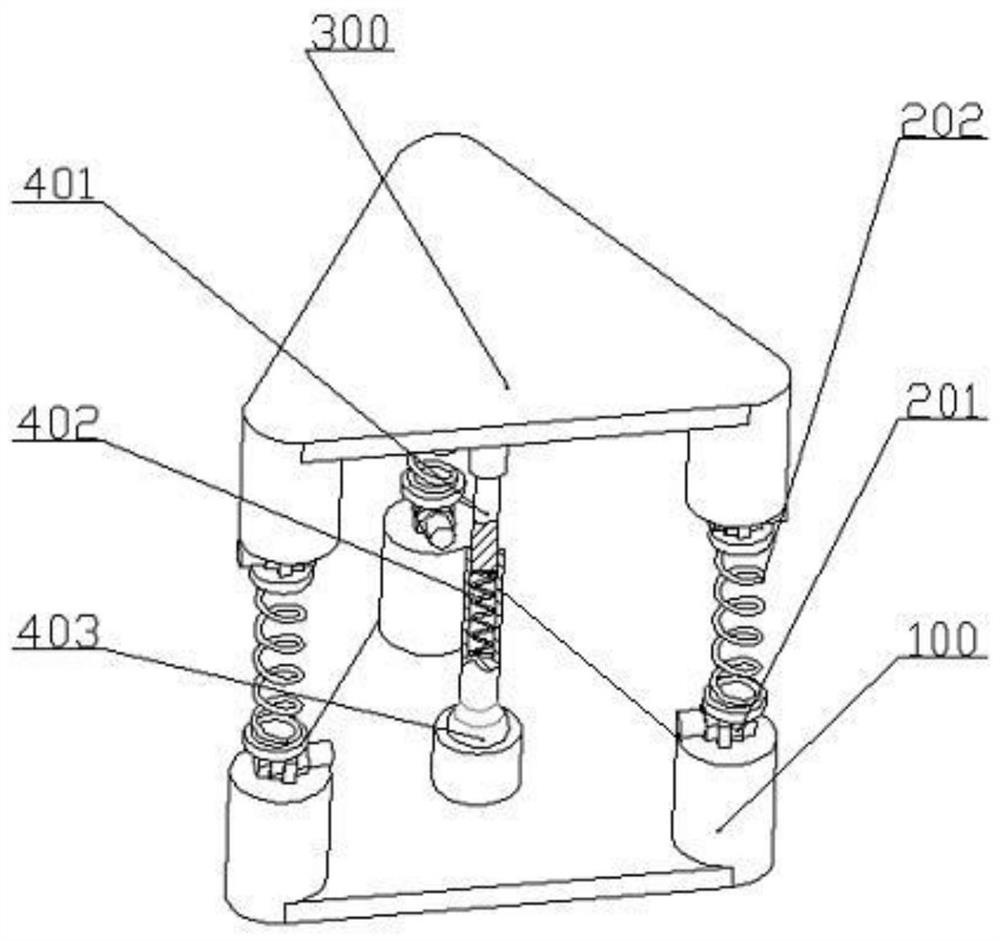

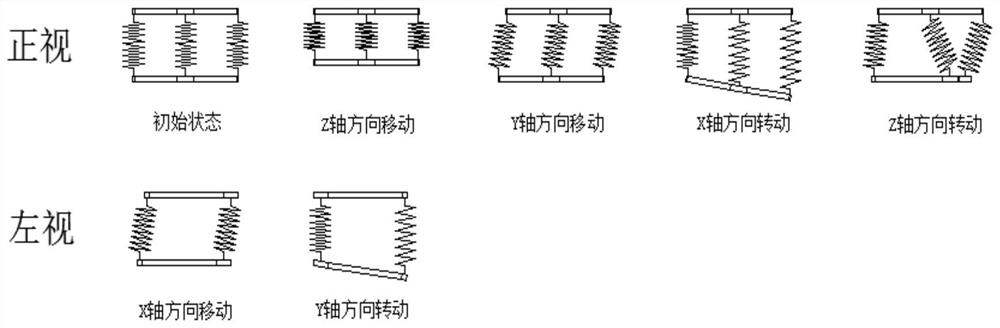

[0018] Please combine Figure 1 As shown, one embodiment of a parallel passive supple device provided for the present invention. The parallel passive supplexing apparatus comprises an upper platform 300, a lower platform 100, a plurality of peripheral branches connected to the upper platform 300 and the lower platform 100, an intermediate branch between the upper platform and the lower platform, the several peripheral branches are set around the intermediate branch. Wherein the lower platform 100 as a dynamic platform. In the present embodiment, the upper platform 300 and the lower platform 100 are equilateral triangle shapes. The upper platform 300 and the lower platform 100 are of the same shape and symmetrical up and down structure. There are three peripheral branches, evenly distributed around the periphery of the upper and lower platforms, that is, connected to the various corners of the platform, the intermediate branches are connected to the geometric center of the upper and...

Embodiment 2

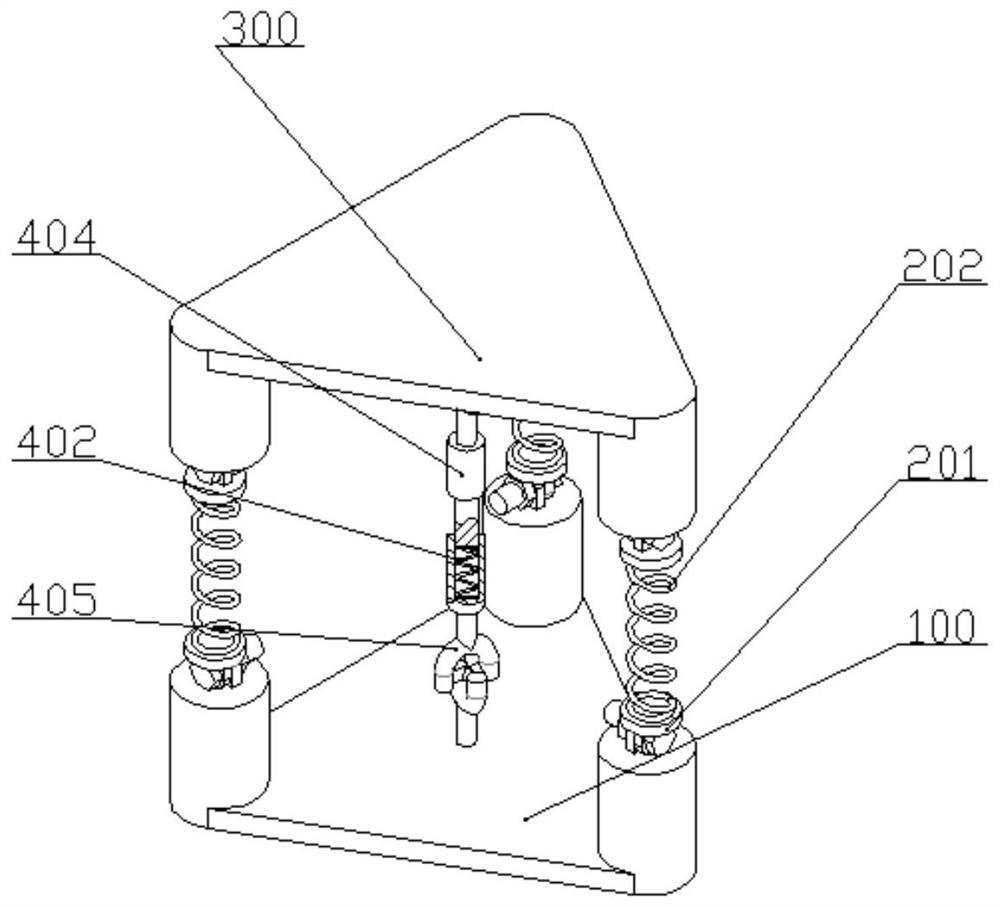

[0020] Please combine Figure 2As shown, one embodiment of a parallel passive supple device provided for the present invention. The parallel passive supplexing apparatus comprises an upper platform 300, a lower platform 100, a plurality of peripheral branches connected to the upper platform 300 and the lower platform 100, an intermediate branch between the upper platform and the lower platform, the several peripheral branches are set around the intermediate branch. In the present embodiment, the upper platform 300 and the lower platform 100 are equilateral triangle shapes. The upper platform 300 and the lower platform 100 are of the same shape and symmetrical up and down structure. There are three peripheral branches, evenly distributed around the periphery of the upper and lower platforms, that is, connected to the various corners of the platform, the intermediate branches are connected to the geometric center of the upper and lower platforms, and each branch is in a vertical stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com