Control system and control method for double-high-speed-wire single-double wire rolling tension adjusting system

A technology for adjusting the system and rolling tension, which is applied in tension/pressure control, metal rolling, metal rolling, etc., and can solve the problems of abnormal double-line looper height, affecting the quality of finished disc shape, and narrowing of pass shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

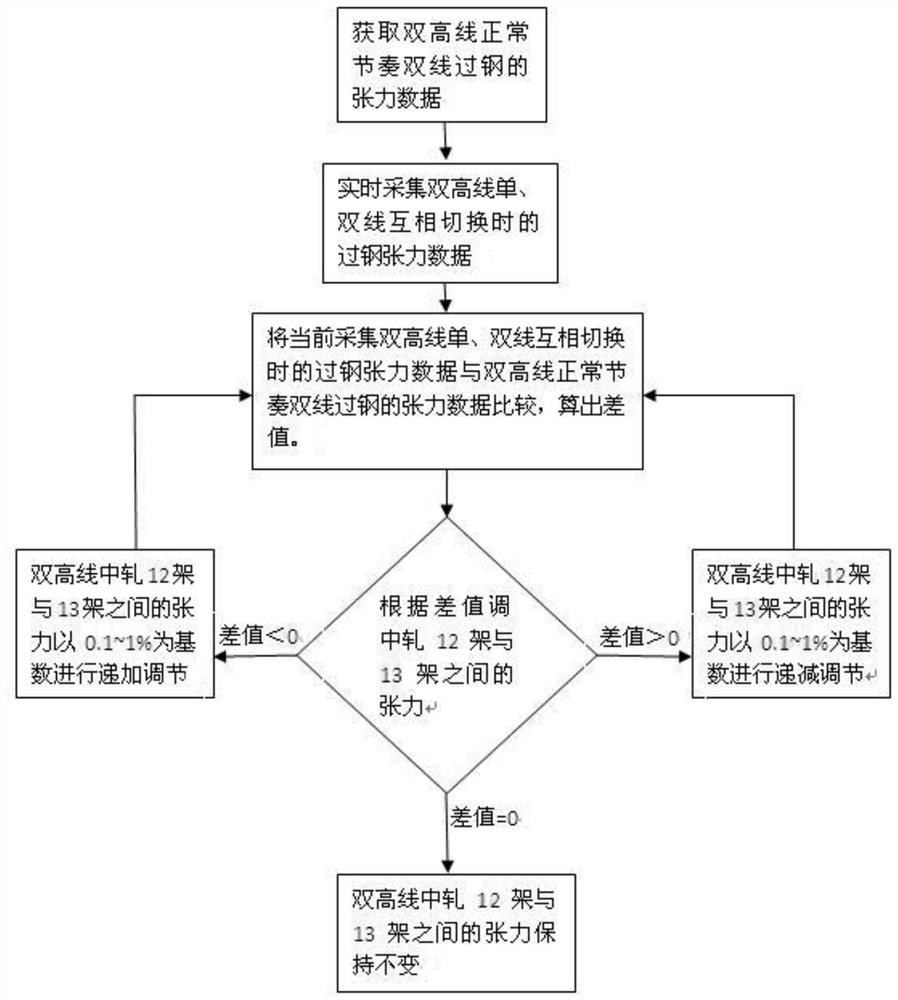

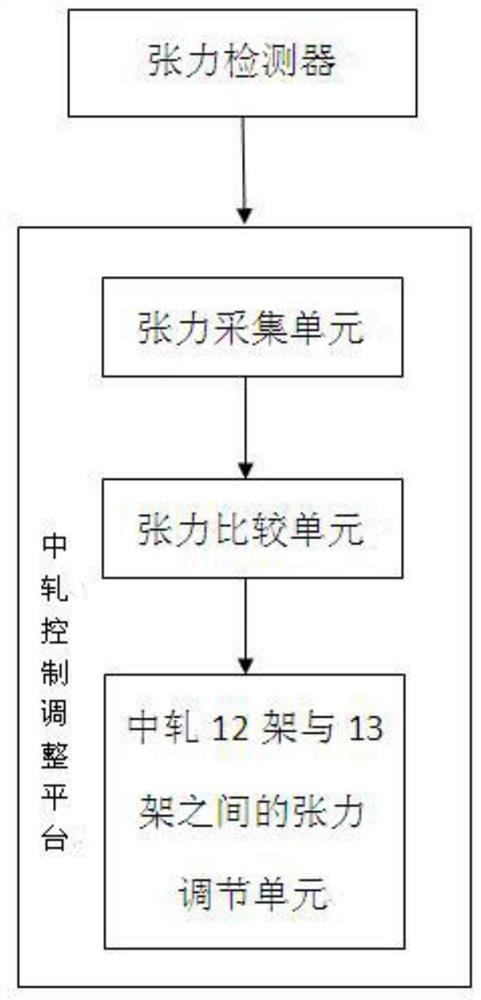

[0028]The present invention provides a method for controlling a tension adjustment system for double-high-line single- and double-line rolling, which includes the following steps:

[0029]S1. Obtain the tension data of the double-high line normal rhythm double-line steel crossing; the time interval for obtaining the tension data of the double-high line normal rhythm double-line steel crossing is t1. In step S2, the real-time acquisition of the double-high line single and double line switching The time interval of steel tension data is t2, t1=t2, t1=50 milliseconds;

[0030]S2, real-time collection of steel tension data when the double-high line single-double line is switched;

[0031]S3. When real-time collection of the steel-passing tension data of the double-high-line single- and double-line switching is compared with the tension data of the double-high-line normal rhythm double-line steel-passing, the steel-passing tension data and The difference between the tension data of the double-hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com