Telescopic cloth arrangement type long net dried bean curd machine

A swing-type, tofu machine technology, applied in cheese substitutes, dairy products, food science, etc., can solve problems such as large reciprocating inertia, achieve the effect of reducing reciprocating structure, ensuring product quality, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

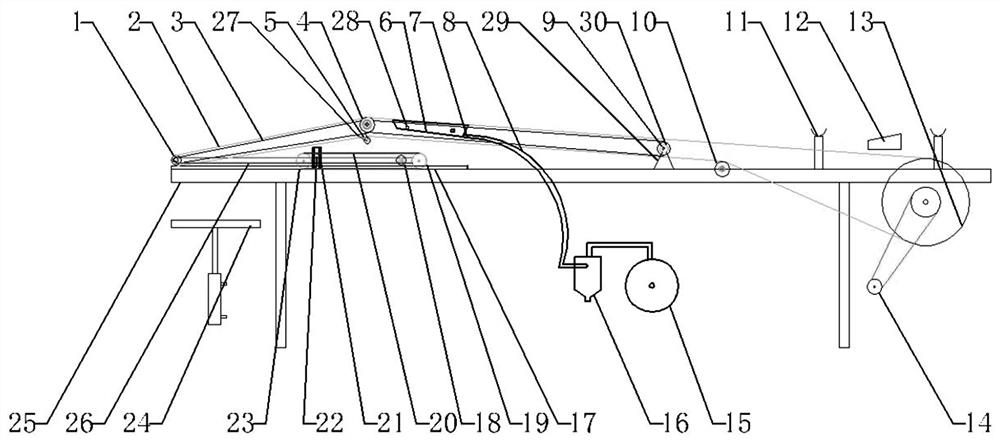

[0023] Such as Figures 1 to 2 As shown, the telescopic side-to-side long net dry tofu machine includes a main frame 25, a slide rail 17, a telescopic shaft reciprocating block 26, a conveyor belt 2, a telescopic shaft 1, a telescopic shaft crank arm 3, a conveyor belt drive shaft 13, and a reciprocating sprocket II19, reciprocating chain 20, reciprocating reduction motor 31, reciprocating sprocket I23, water suction tank 6, hose 8, vortex air pump 15, etc., one end of the main frame 25 is equipped with a conveyor belt drive shaft 13, and the other end of the main frame 25 One end is provided with slide rail 17, and telescopic shaft reciprocating block 26 is slidably installed on slide rail 17, and pulley 18 is arranged under telescopic shaft reciprocating block 26, and bearing is inlaid in pulley 18, and telescopic shaft reciprocating block 26 can pass through pulley 18 on slide rail 17. Slide up and down.

[0024] The telescopic shaft reciprocating pulley 26 is connected wi...

Embodiment 2

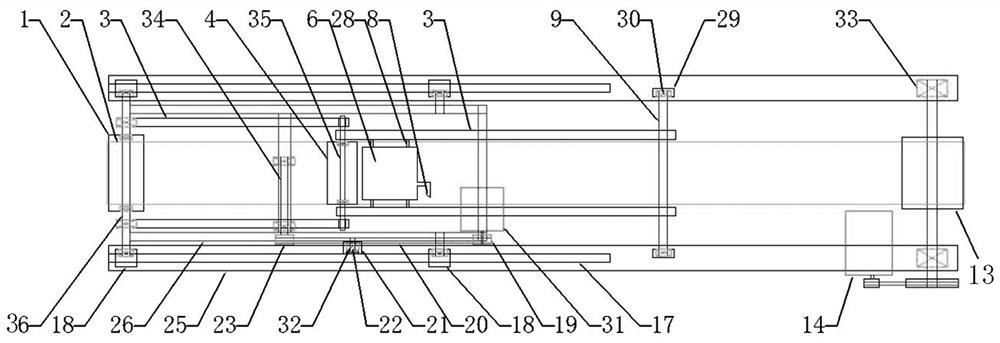

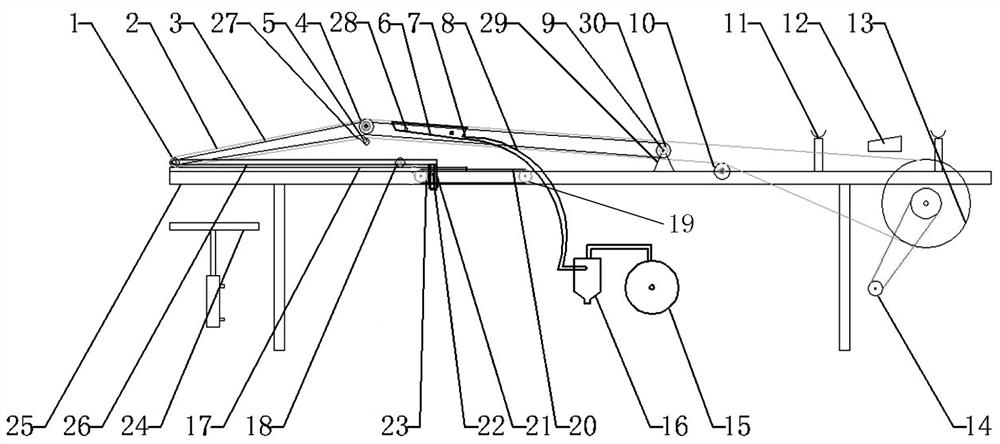

[0029] Such as image 3 , Figure 4 As shown, a reciprocating reduction motor and a reciprocating shaft are installed on the main frame 25, a reciprocating wheel II19 is installed on the reciprocating reduction motor shaft, a reciprocating sprocket I23 is installed on the reciprocating shaft 34, and a reciprocating chain is wound on the reciprocating sprocket II19 and the reciprocating sprocket I23 20. The value of the reciprocating slide rail 21 is fixed on the telescopic shaft reciprocating pulley 26, one end of the reciprocating bearing fixed shaft 32 is fixedly installed on the reciprocating chain 20, the other end of the reciprocating bearing fixed shaft 32 extends into between the reciprocating slide rails, and the reciprocating bearing is fixed Axle 32 stretches into the termination of reciprocating slide rail and reciprocating bearing 22 is installed, and reciprocating bearing 22 can only reciprocate up and down in the chute of reciprocating slide rail 21. Other struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com