Automatic dried beancurd stick deep-frying production line

An automated production line and technology for yuba, applied in oil/fat roasting, chemical instruments and methods, filtration and separation, etc., can solve the problems of brittleness, excessive peroxide value, low production efficiency of fried yuba, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

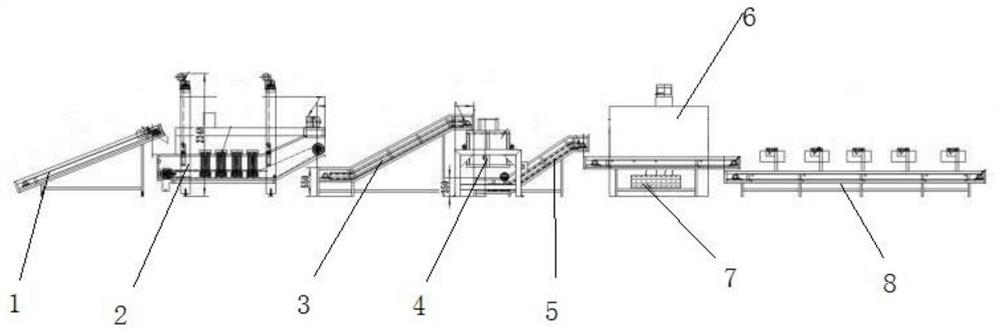

[0023] see figure 1 , the present invention provides an automatic production line for frying bean curd sticks, comprising a conveyor 1, a frying machine 2, an elevator I3, a drying machine 4, an elevator II5, a moisture regainer 6, a steam generating device 7 and a cooling machine 8. The end of the conveyor 1 is set at the feed port of the fryer 2, the lifter I3 is set at the discharge port of the fryer 2, the drying machine 4 is set at the end of the lifter I3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com