High-speed rail straight line segment multimode AI accurate measurement robot

A straight line segment and robot technology, applied in the direction of measuring instruments, radio wave measuring systems, instruments, etc., can solve the problems of affecting operation efficiency, short operation time of skylights in operation lines, and waste of operation time, so as to improve measurement efficiency and improve operation Efficiency and the effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

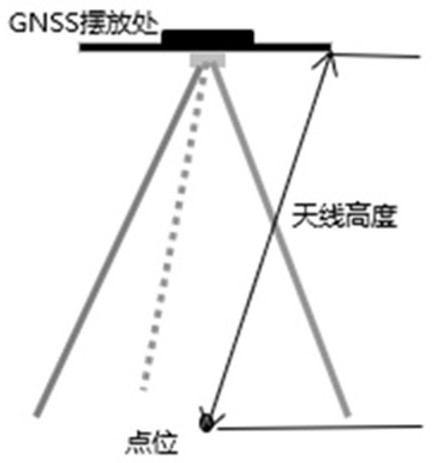

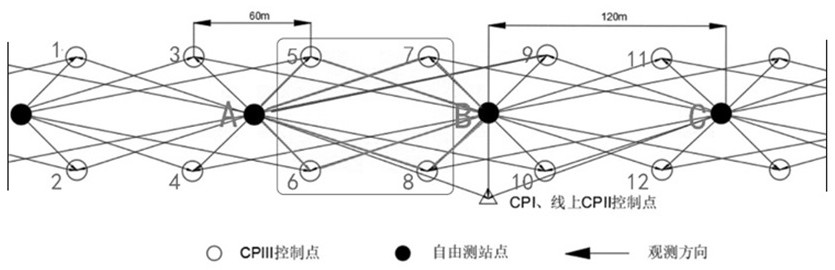

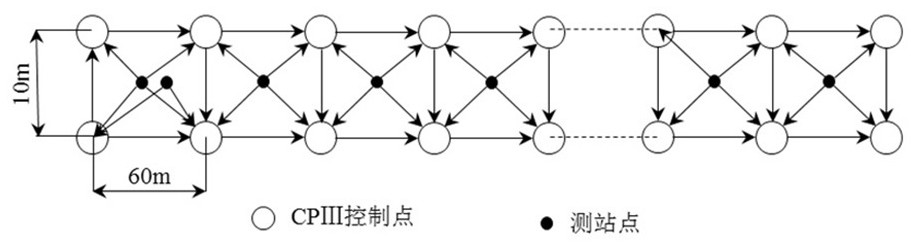

[0043]Embodiment: In this embodiment, the multi-mode AI precise measurement robot in the straight line section of the high-speed rail integrates the GNSS receiver, the level, and the total station, and is divided into three modules: the automation level of the line or track control network, and the track control network ( CPIII) plane measurement and basic or line control network (CPI, CPII) plane measurement module to get rid of the manual intervention of traditional surveying and mapping, and realize the automatic measurement without manual intervention in the high-speed rail precision measurement network project. Human operation only needs to select the corresponding measurement module. , the invention reduces operating tools, improves measurement efficiency, and reduces labor costs. The following describes the multi-mode AI precision measurement robot in this embodiment in combination with the measurement principle and corresponding operation method, as follows:

[0044] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com