Full-automatic concrete mixer

A concrete mixer, fully automatic technology, applied in the direction of selling raw material supply devices, etc., can solve the problems of inability to realize mixing, deformation of baffle plates, inability to meet angle adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

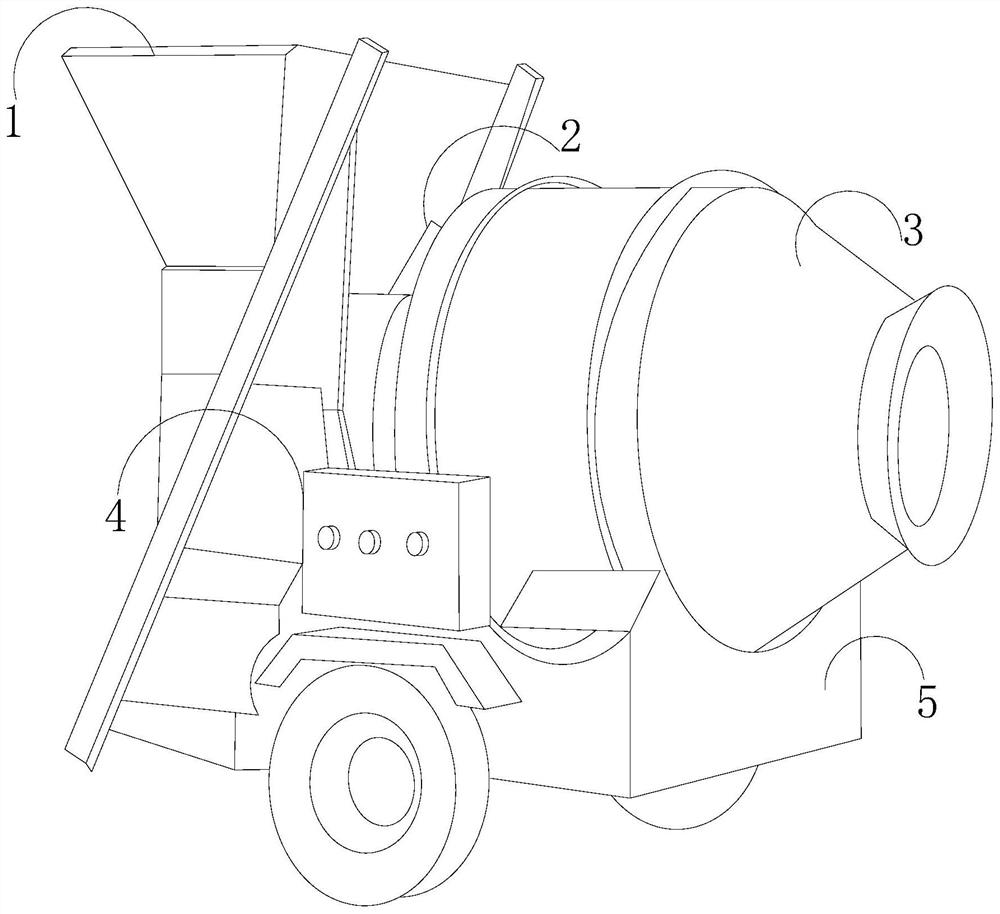

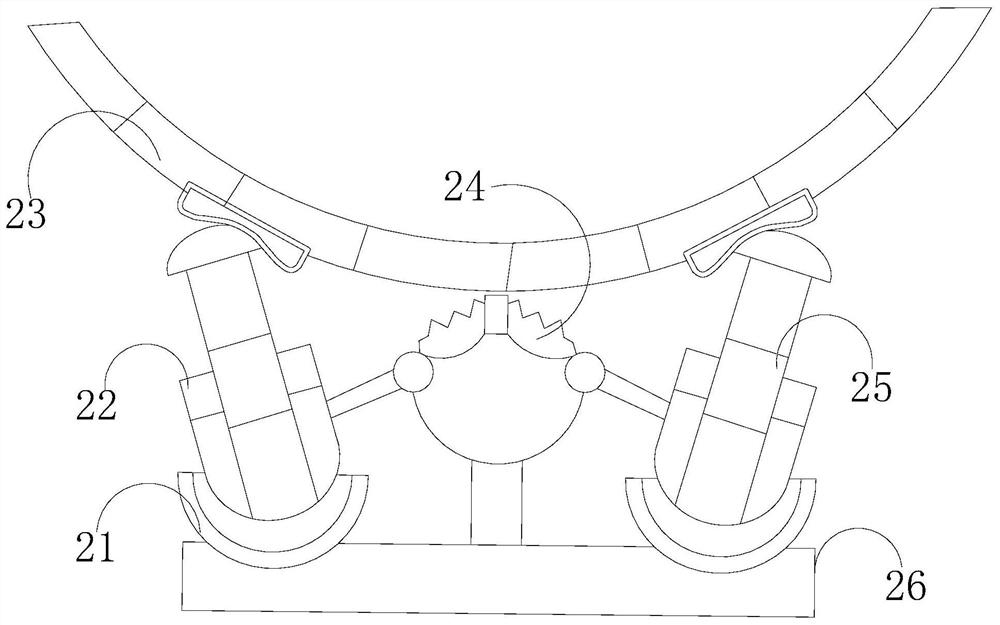

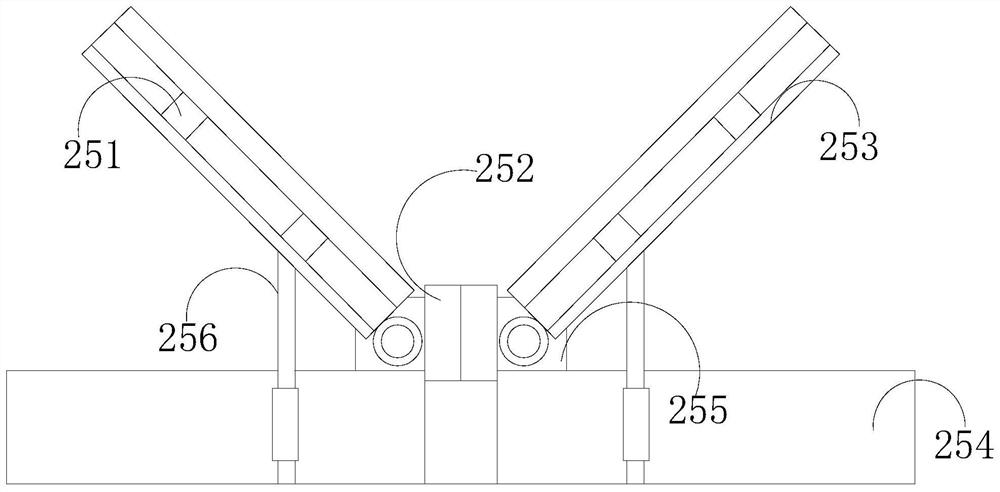

[0028]Such asFigure 1-Figure 6As shown, the present invention provides a fully automatic concrete mixer, the structure of which includes a discharging port 1, a material guide 2, a mixing tank 3, a control box 4, and a machine base 5. Between the discharging port 1 and the mixing tank 3 A guide device 2 is provided. The guide device 2 extends to the inside of the mixing tank 3. The mixing tank 3 and the control box 4 are electrically connected, and the bottom of the mixing tank 3 is installed in the recess of the machine base 5. The material device 2 includes a swinging recess 21, a support plate 22, a material baffle 23, a gathering member 24, an adjustment structure 25, and a balance control 26. The swinging recesses 21 are symmetrically distributed along the gathering member 24 at both ends of the balance control 26, The support plate 22 and an adjustment structure 25 are oscillatingly fitted inside. The support plate 22 is fixedly installed on both sides of the adjustment struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com