Equal-distance thread progressive type small bolt dismounting tool and using method

A technology of equidistant thread and bolt disassembly and assembly, which is applied in the direction of manufacturing tools, screwdrivers, wrenches, etc., can solve the problems of damaged bolt heads, difficult bolt installation, bolts cannot be disassembled normally, etc., and achieve the effect of effective transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the objectives, technical solutions and beneficial effects of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is only some embodiments of the present invention, but not all embodiments.

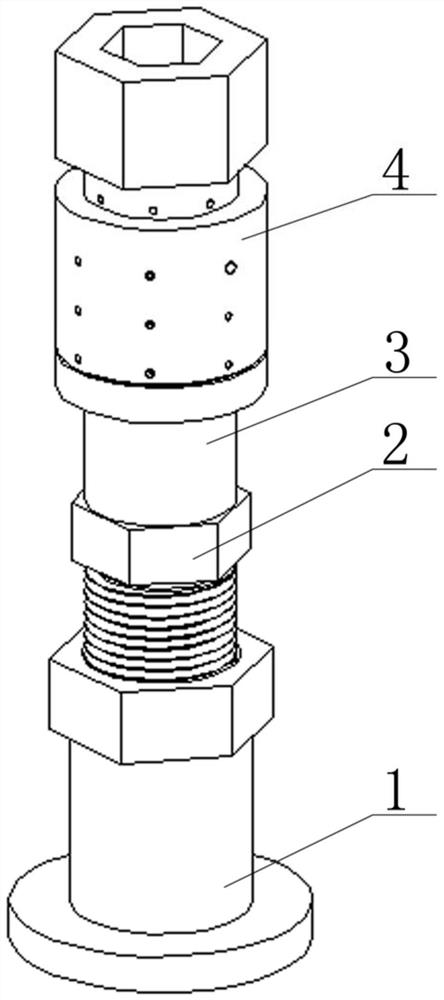

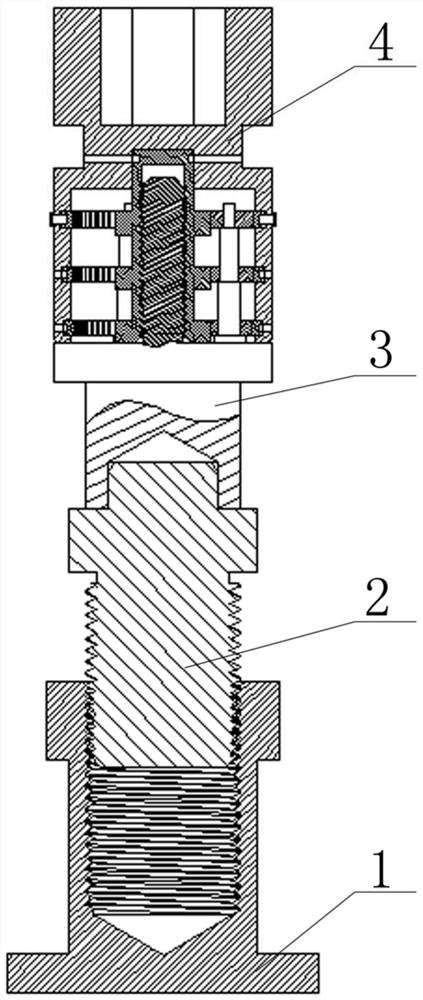

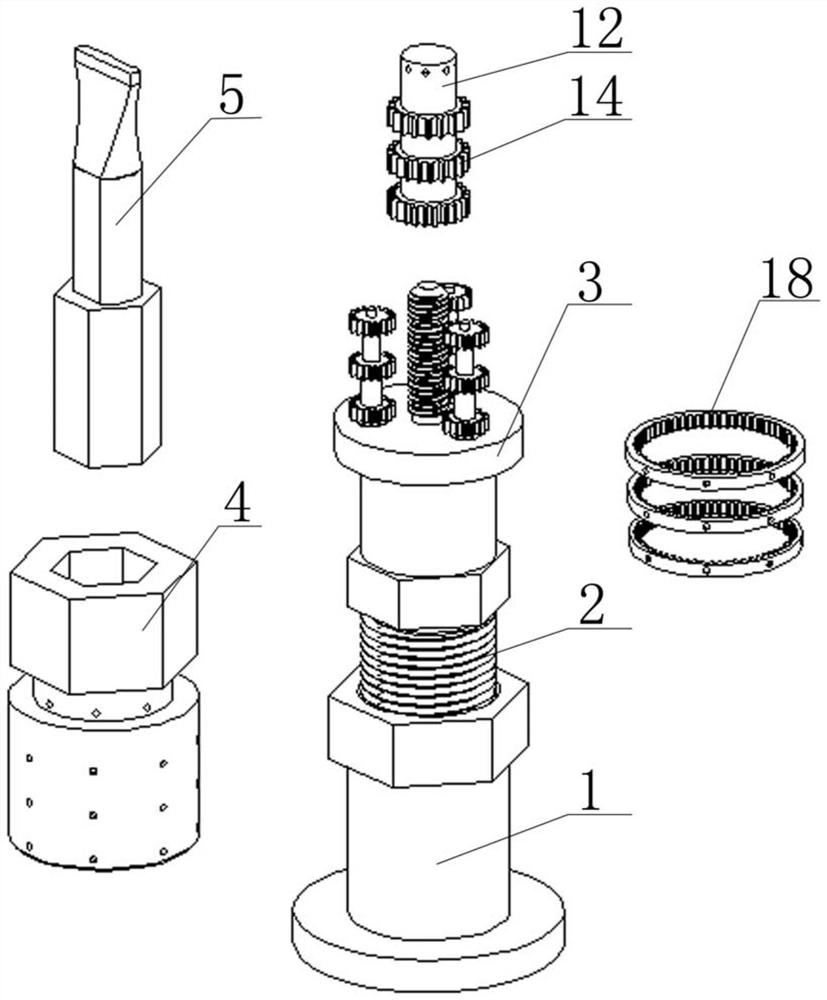

[0064] Such as Figure 1 to Figure 19 As shown in the figure, a progressive small-sized bolt removal tool with equidistant threads is used with a hexagonal open-end wrench, and includes a base 1, a lifting screw 2, a support seat 3, a drive sleeve 4 and an actuator head 5 connected sequentially from bottom to top;

[0065] The bottom of the base 1 and the lifting screw 2 is connected by the first screw thread 6, and the upper end of the lifting screw 2 is provided with a boss 7 and a rotating part 8, and the boss 7 is placed on the rotating par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com