Construction waste treatment device

A processing device and technology for construction waste, applied in grain processing, magnetic separation, solid separation, etc., can solve the problems of classified collection of construction waste and construction waste, affecting the recycling rate of construction waste, and the failure of construction waste to be recycled. Improve the surrounding environment, reduce dust flying, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with accompanying drawing:

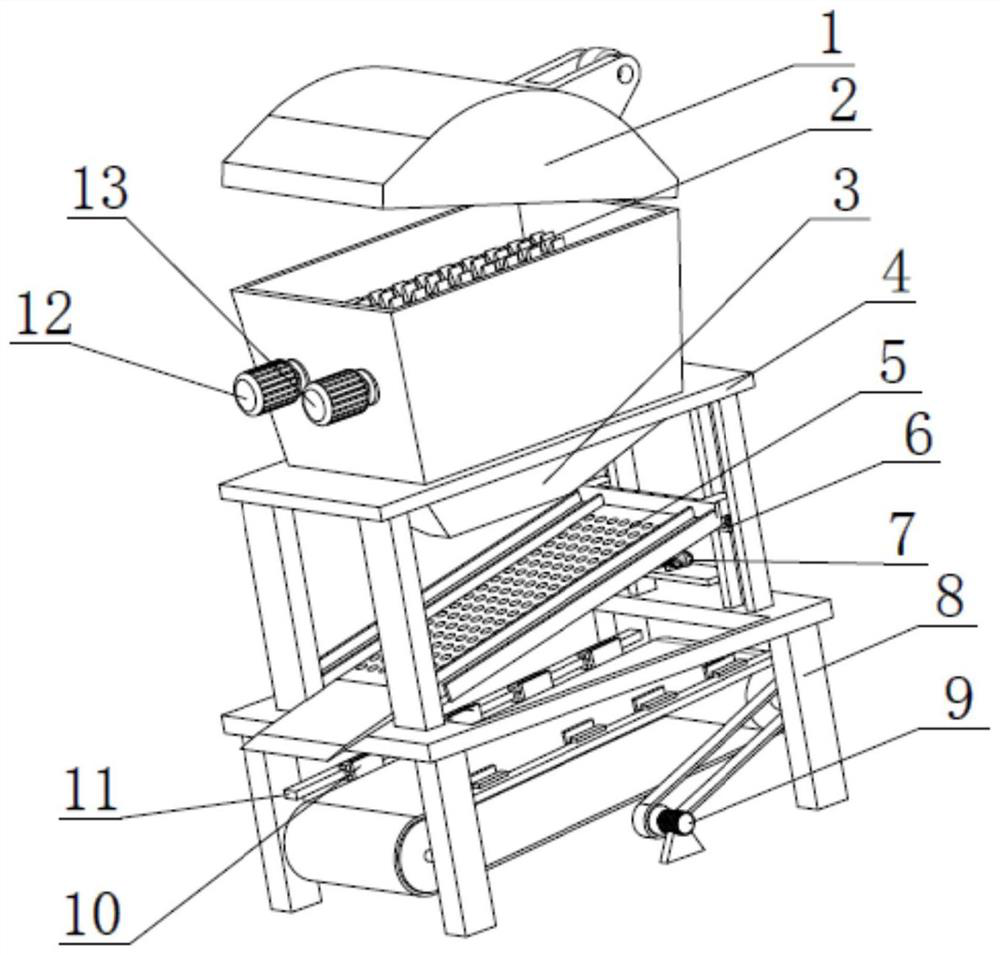

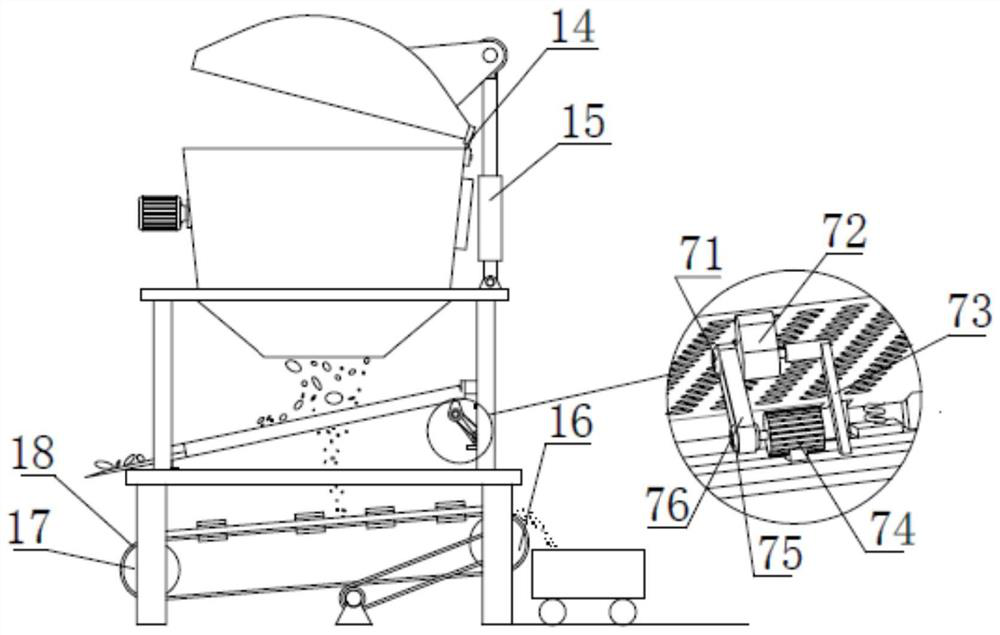

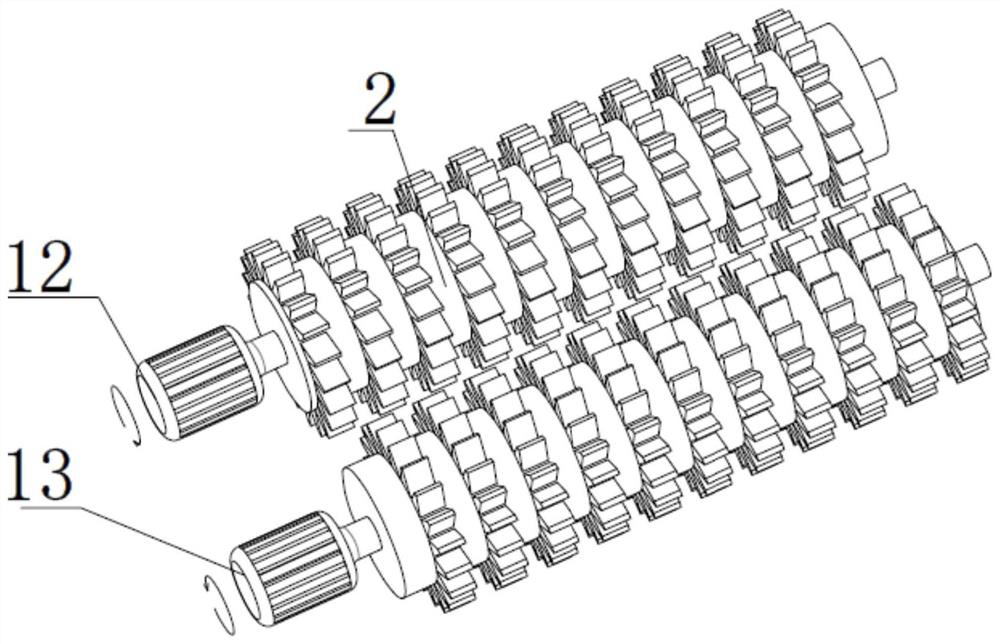

[0026] see Figure 1 to Figure 4 , a multi-functional construction waste treatment equipment, comprising a crushing device, a screening device, and a sorting device. The crushing device is supported by the first support frame, including a crushing mechanism, a feed box, a discharge port, and a spray mechanism; the feed box is located on the top of the equipment, including a box body and a box cover, and a box body and a box cover The opening and closing of the box cover is controlled by a hydraulic mechanism; the crushing mechanism is installed in the feed box, and the crushing teeth are driven by the first motor and the second motor to reversely rotate to realize the crushing of construction waste; The spraying mechanism is located inside the cover of the feed box and placed obliquely; the discharge port is located below the feed box.

[0027] Further, the screening device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com