A hobless hard rock tunneling machine using microwave and high-pressure water jet to break rock

A technology of high-pressure water jet and hard rock roadheader, which is applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of long construction period and high cost, and achieve the effect of reducing excavation cost, light weight and improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

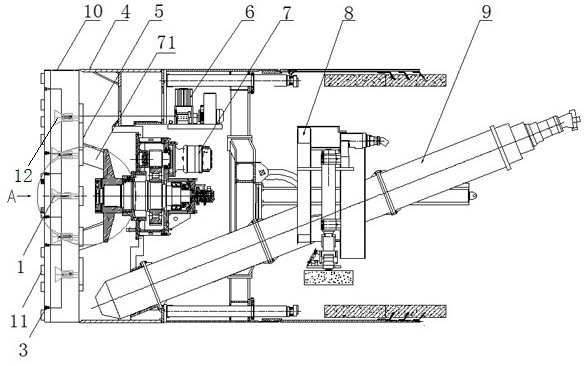

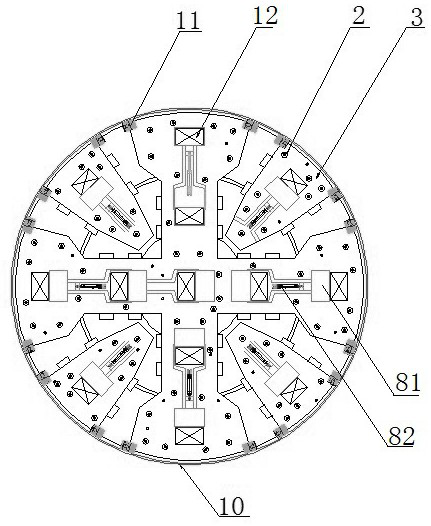

[0031] Embodiment 1, a kind of hard rock tunneling machine without hob that utilizes microwave and high-pressure water jet to break rock, such as figure 1 As shown, including the shield body 4, the center main drive system 7 is arranged in the shield body 4, and the center main drive system 7 is connected with or without the hob cutter head 3 through a connecting frame 71 with a span greater than one meter. The center main drive system 7 can be large The span connecting frame 71 drives the hobless cutter head 3 to rotate in the circumferential direction. A segment assembly machine 8 and a screw conveyor 9 are arranged inside the shield body 4 , and the feeding end of the screw conveyor 9 is located at the rear side adjacent to the hobless cutter head 3 .

[0032] The large-span connection frame 71 can construct enough installation space between the hobless cutterhead 3 and the central main drive system, and the rear side of the hobless cutterhead 3 is provided with a microwave...

Embodiment 2

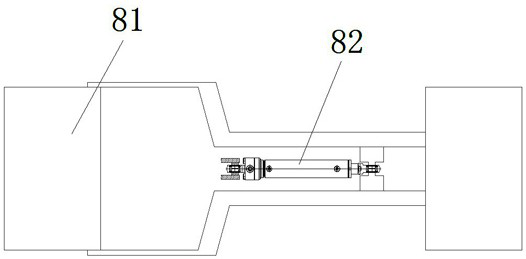

[0036] Embodiment 2, a kind of hard rock tunneling machine without hob that utilizes microwave and high-pressure water jet to break rock, such as Figure 5 As shown, the microwave radiation arm 1 is retractable, and the retractable microwave radiation arm 1 can be adjusted according to the distance between the hobless cutter head 3 and the rock, so that the microwave radiation arm 1 can always closely fit the rock section , to avoid excessive scattering or reflection of microwaves to reduce heat dissipation efficiency.

[0037] The microwave radiation arm 1 includes a microwave emission terminal 12 that is plugged and matched with the hobless cutterhead 3, the microwave emission terminal 12 is connected with a first telescopic cylinder 13, and one end of the first telescopic cylinder 13 is connected with the microwave emission terminal 12 , the other end links to each other with the hob-free cutter head 3, and the expansion and contraction of the first telescopic cylinder 13 c...

Embodiment 3

[0040] Embodiment 3, a hob-less hard rock tunneling machine that uses microwaves and high-pressure water jets to break rocks. The first pneumatic telescopic cylinder or the first hydraulic telescopic cylinder is provided with a pressure sensor connected to the controller, and the controller is connected to There is a first solenoid valve for controlling the on-off of the air inlet of the first pneumatic telescopic cylinder or the liquid inlet of the first hydraulic telescopic cylinder. The pressure sensor can monitor the pressure in real time, and the controller can control the on-off of the first electromagnetic valve in real time according to the monitored pressure, and then control the telescopic state of the first pneumatic telescopic cylinder or the first hydraulic telescopic cylinder.

[0041] A threshold is set in the controller to control the pressure in the first pneumatic telescopic cylinder or the first hydraulic telescopic cylinder to be constant, and the real-time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com