Construction process of retarded concrete wall body

A technology for concrete walls and construction techniques, applied in the field of construction engineering, can solve the problems of inability to meet the development needs of the construction engineering industry, limited natural gypsum mining capacity, and influence on the setting strength of concrete, achieving important environmental protection significance and economic significance, and saving natural resources. Gypsum resources, strong setting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

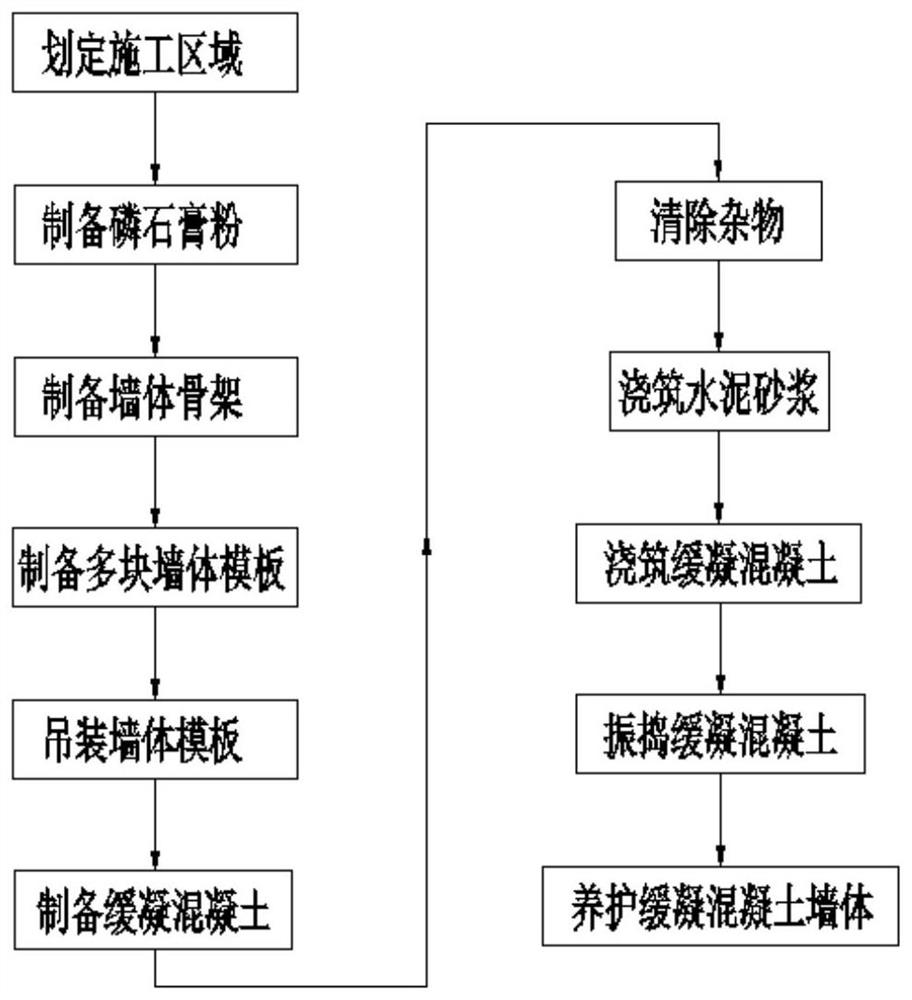

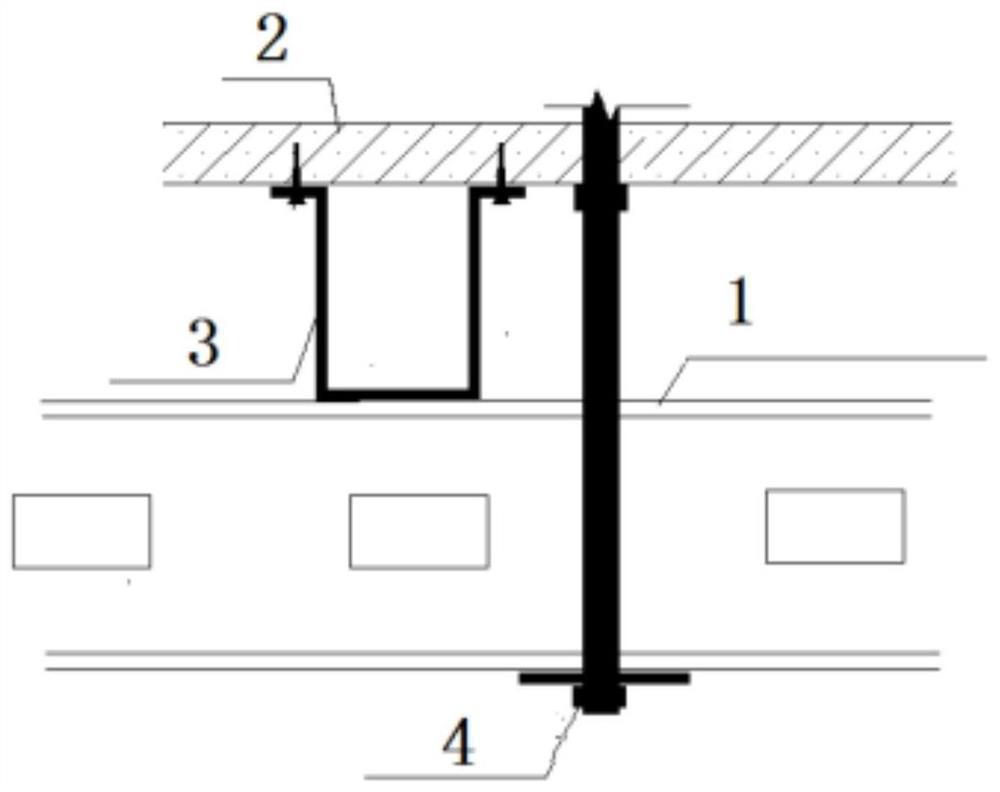

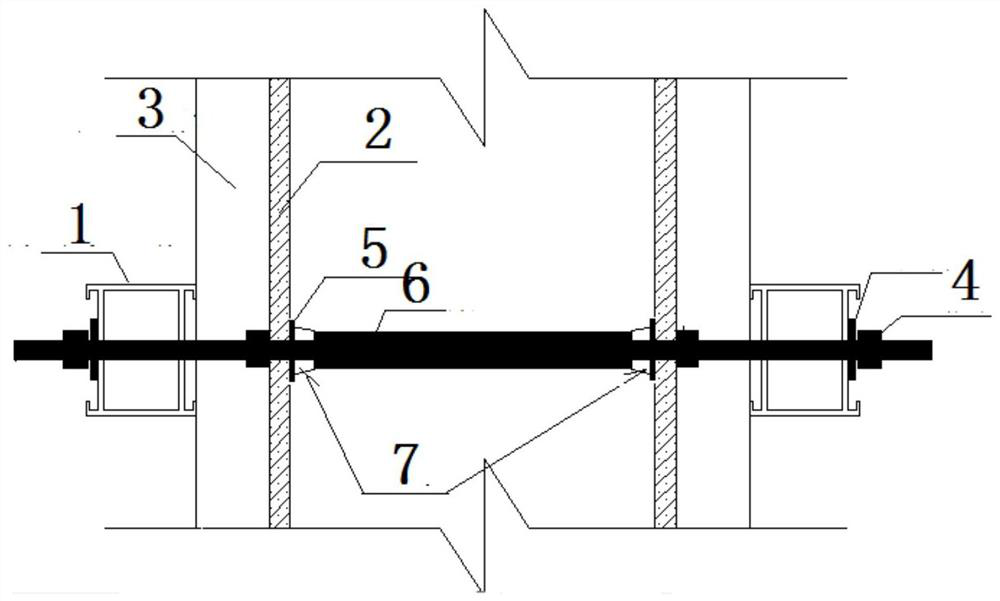

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the present invention provides a kind of retarded concrete wall construction technology, comprises the following steps:

[0054] Step 1: Delineate the construction area: According to the construction drawings, draw a closed circular outline on the ground as the construction area;

[0055] Step 2: Preparation of phosphogypsum powder: input phosphogypsum powder containing water into the airflow dryer for dehydration and drying to obtain phosphogypsum powder. The drying time is 1-4 hours, the drying temperature is controlled at 150-180°C, and the water content of phosphogypsum powder is ≤ 3%;

[0056]Step 3: Prepare the wall skeleton: lay out several vertical steel bars erected on the ground in the construction area mentioned in step 1, and then arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com