A kind of antiaging composition and bopp film

A composition and anti-aging technology, applied in the field of polymer additives, can solve problems such as redness of the end surface of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention has no special limitation on the preparation method of the film material of the BOPP film, which can be obtained by melting and blending the base material and the anti-aging composition, and then extruding and granulating. In the present invention, there is no special limitation on the preparation method of the BOPP film from the film material, and it can be carried out according to the conventional film making method well known to those skilled in the art.

[0075] The BOPP film provided by the invention is added with the anti-aging agent composition provided by the invention, so it exhibits excellent abnormal performance. The experimental results show that: compared with the BOPP film material added with traditional anti-aging agent, the BOPP film material provided by this application has no adverse effect on the haze, low friction coefficient and ash content, significantly improved long-term anti-aging effect, and effectively solved the phenomeno...

Embodiment 1

[0078] 1.1 Anti-aging composition formula:

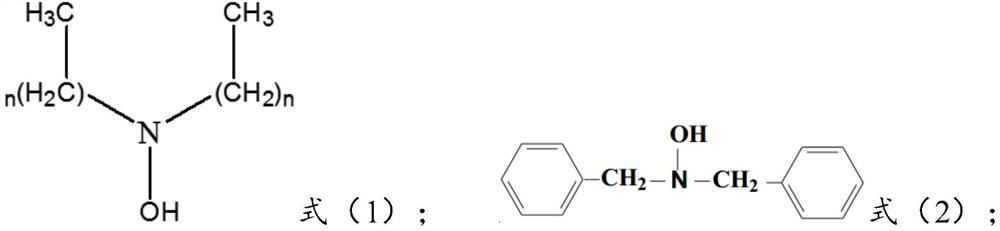

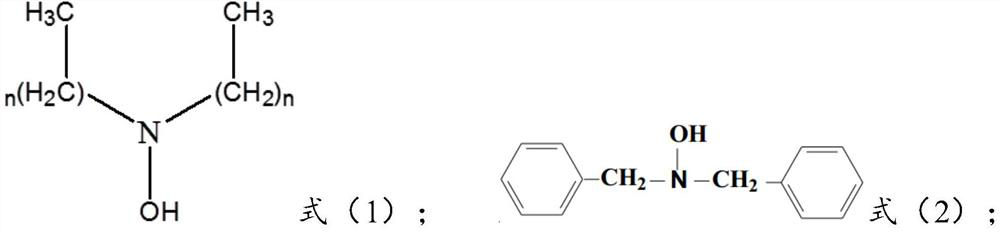

[0079] The mass ratio of formula (1) amine synergist (n=17) to base material is 0.04%;

[0080] The mass ratio of hindered phenolic antioxidant 1076 to amine synergist is 0.8:1;

[0081] Phosphite antioxidant: the mass ratio of 168+626 to amine synergist is 1:1;

[0082] (Antioxidant 168:626 mass ratio=1:2.5);

[0083] Acid absorbing agent: the mass ratio of CaSt+hydrotalcite-like 401A to amine synergist is 1:1;

[0084] (CaSt: hydrotalcite-like mass ratio = 3: 1);

[0085] The mass ratio of processing aid PPA to amine synergist is 0.5:1;

[0086] The mass ratio of antistatic agent GMS to amine synergist is 0.75:1.

[0087] The mass ratio of the base material: the above aging composition = 100:0.26.

[0088] 1.2 Preparation of BOPP film

[0089] S1, mix the anti-aging composition and 5000g base material evenly;

[0090] S2, the resulting mixture is extruded and granulated in a twin-screw extruder (length-to-diameter ratio is...

Embodiment 2

[0100] 1.1 Anti-aging composition formula:

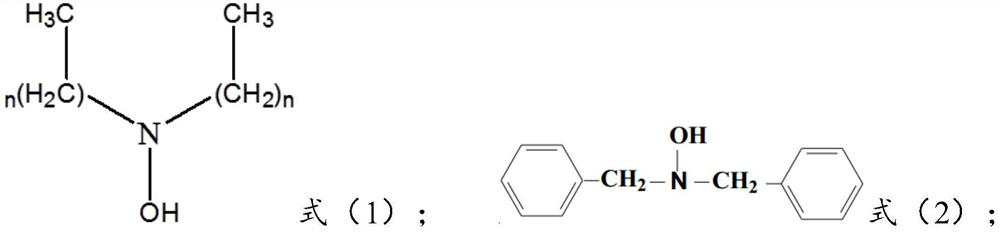

[0101] Formula (1) amine synergist (n=15) Formula (1)+Formula (2) together account for 0.04% of the mass ratio of the base material;

[0102] Formula (2) amine synergist Formula (1): formula (2) mass ratio=3:1;

[0103] Hindered phenolic antioxidant: the mass ratio of 1076+1425 to amine synergist is 1.25:1;

[0104] (Antioxidant 1076:1425 mass ratio=1.5:1);

[0105] Phosphite antioxidant: the mass ratio of 168+626 to amine synergist is 2.5:1;

[0106] (antioxidant 168:626 mass ratio=1:1);

[0107] Acid absorbing agent: the mass ratio of CaSt+hydrotalcite-like 401A to amine synergist is 1:1;

[0108] (CaSt: hydrotalcite-like mass ratio = 1: 1);

[0109] The mass ratio of processing aid PPA to amine synergist is 0.5:1;

[0110] The mass ratio of antistatic agent GMS to amine synergist is 0.75:1.

[0111] The mass ratio of base material: the above aging composition = 100:0.28.

[0112] 1.2 Preparation of BOPP film: Same as Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com