Oil discharge device and steamer

A technology of oil discharge device and steamer, which is applied in the field of steamer, can solve the problems of affecting the quality of fabrics, unable to disperse oil fume in time, and achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

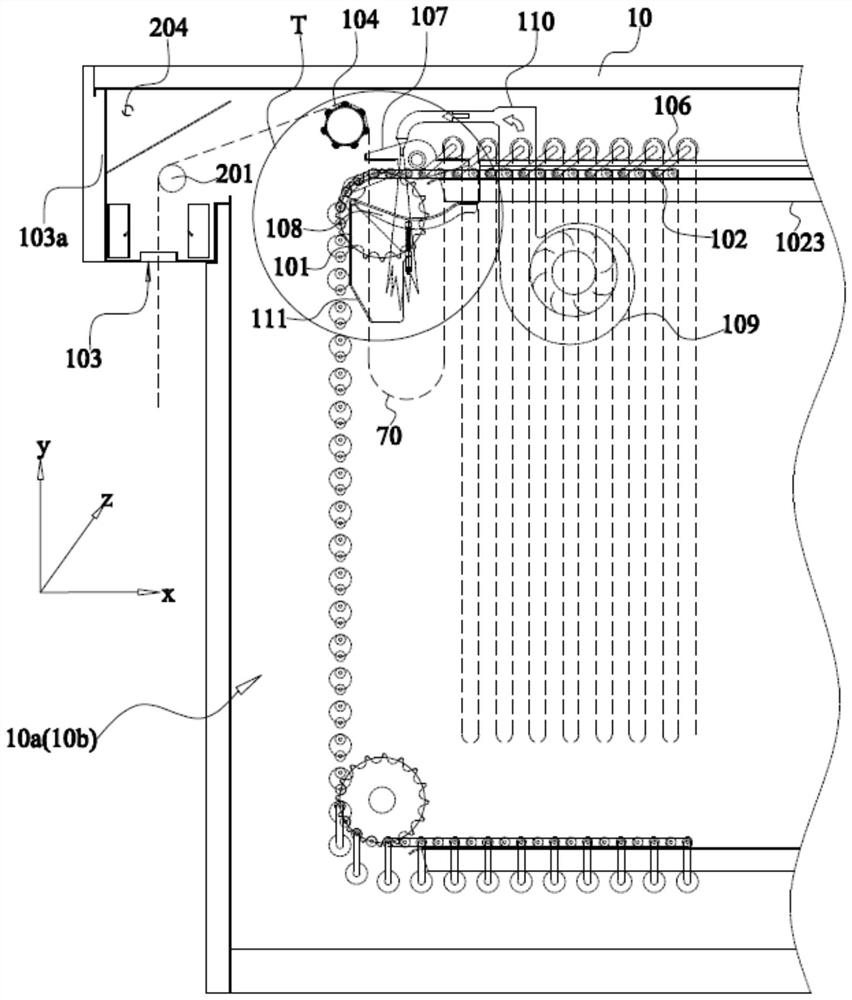

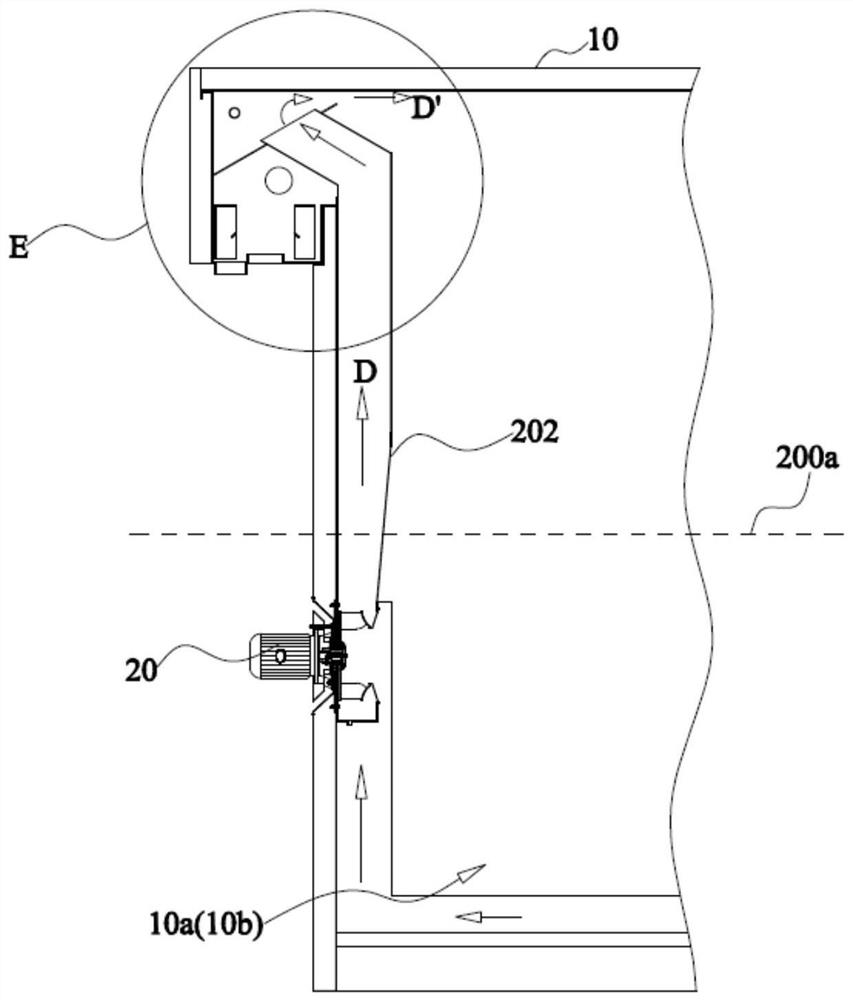

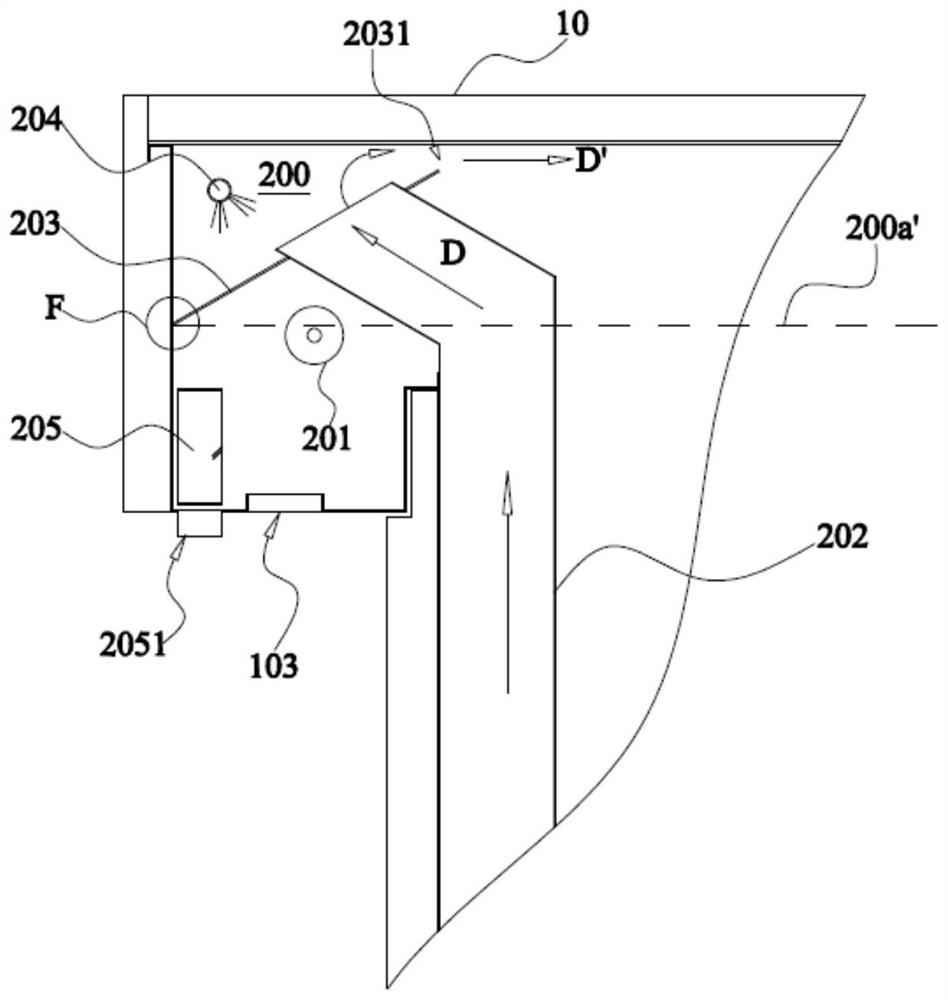

[0047] Please refer to a specific implementation of a steaming machine according to an embodiment of the present invention shown in FIG. 1 to FIG. 10 .

[0053] Wherein, the top of the anti-drip plate 203 is lower than the free end of the anti-drip plate 203, and the top of the anti-drip plate 203 is formed to drain oil

[0057] In this embodiment, the steamer makes the cloth rest roller 105 move through the crank assembly 106 connected to both sides of the cloth rest roller 105.

[0060] Continue to describe with reference to FIG. 1 and FIG. 6, in any of the above-mentioned embodiments, a support seat is arranged below the support plate 108

[0061] It should be noted that the horizontal section of the support plate 108 is configured as an arc shape, and the recessed portion of the support plate 108 is gradually oriented

[0064] The series of detailed descriptions listed above are only specific to the possible embodiments of the present invention.

[0065] Furthermore, it should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com