An energy-saving and environment-friendly treatment system for high-temperature flue gas

A technology of energy saving, environmental protection and treatment system, applied in the field of dust removal machinery and equipment, can solve the problems of waste of energy consumption, reduction of flue gas purification treatment efficiency, increase of flue gas volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

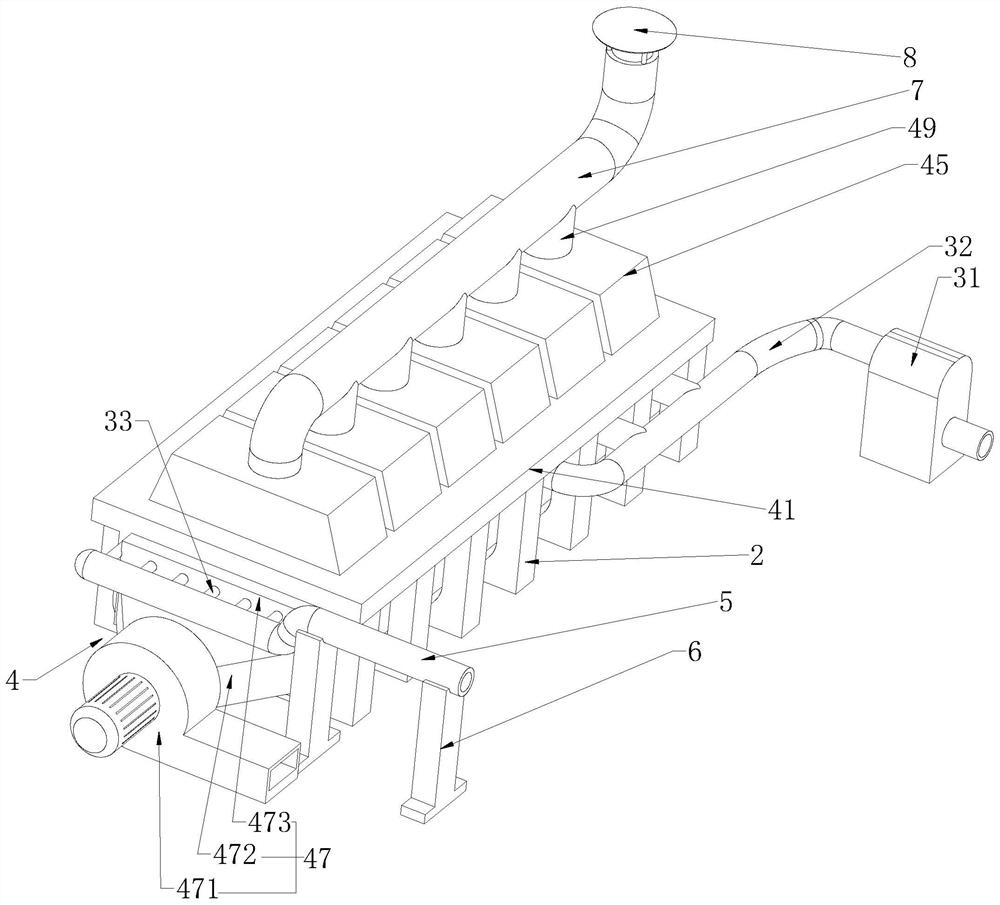

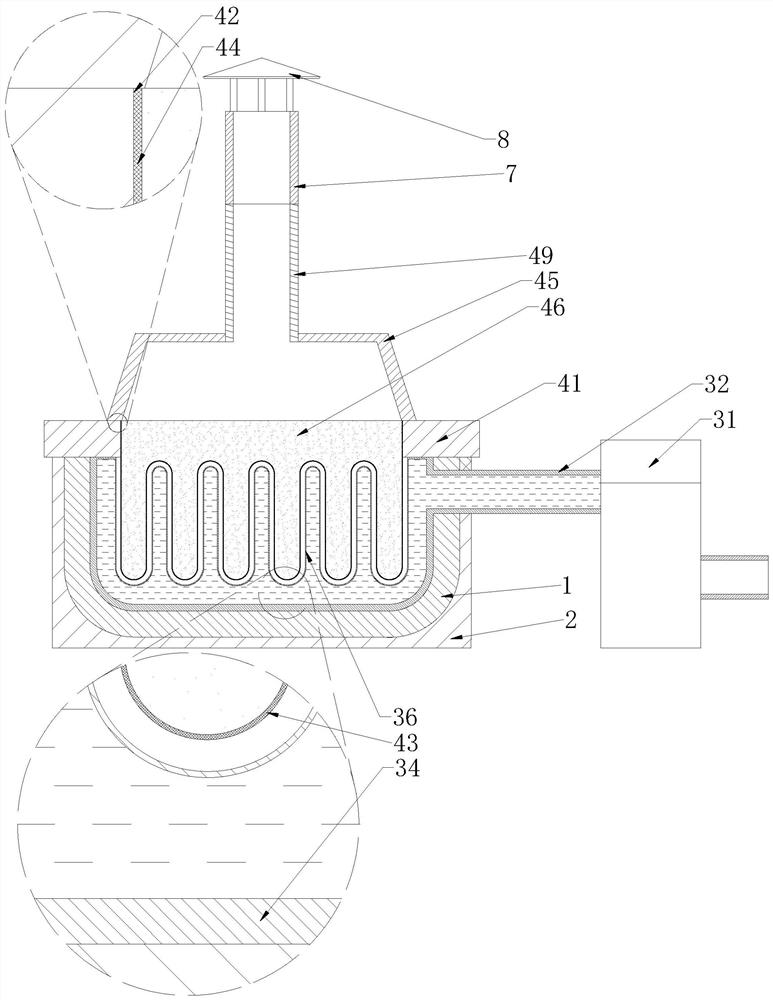

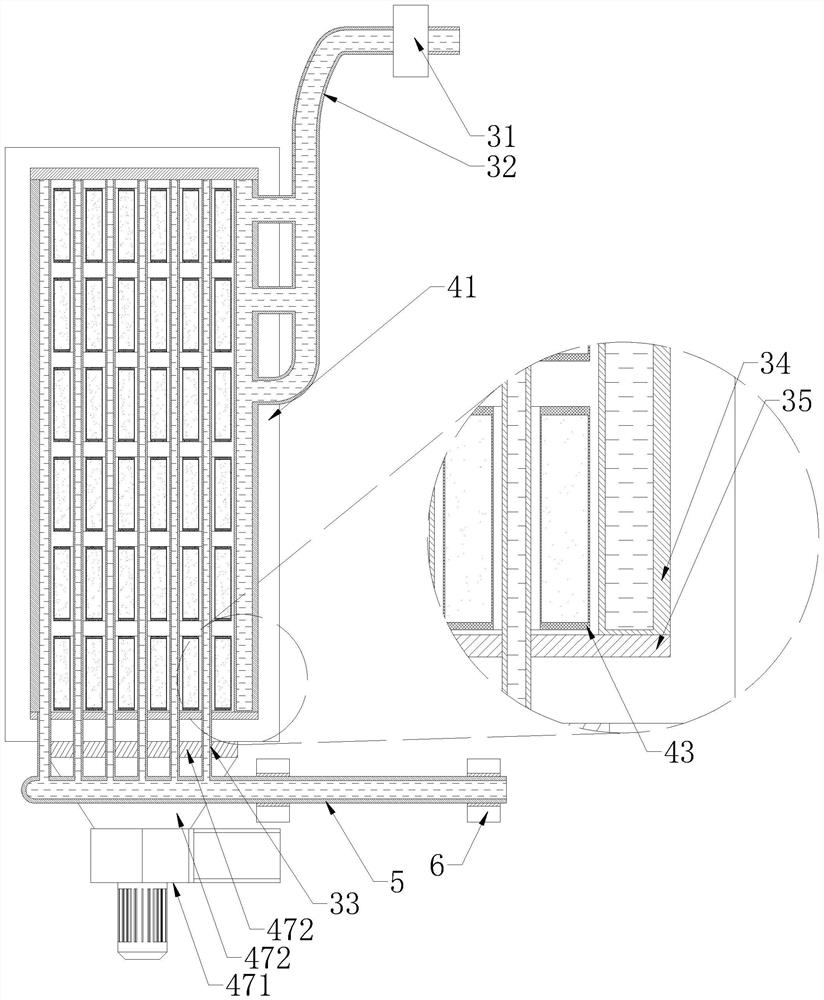

[0025] The following is attached Figure 1-6 The present invention is described in further detail.

[0026] It is an energy-saving and environment-friendly treatment system for high-temperature flue gas of the present invention, which includes a U-shaped installation platform 1, a support frame 2, a heat energy recovery device, and a purification device 4. Several support frames 2 are linearly distributed on the ground, and the U-shaped installation platform 1 It is installed on several supporting frames 2 with the opening facing upwards, and the heat energy recovery device and the purification device 4 are installed.

[0027] The heat energy recovery device includes a water pump 31, a water inlet pipe 32, a water outlet pipe 33, a U-shaped cylinder 34, a U-shaped plate 35 and a heat exchange cylinder 36. Both ends of the mouth of the cylinder are equipped with a 匚-shaped plate 35, and several heat exchange cylinders 36 are evenly arranged on the inner and outer walls of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com