A kind of demulsification separation device for vaccine processing

A separation device and demulsification technology, which is applied in the field of vaccine cultivation, can solve the problems of inability to emulsify vaccines, low demulsification efficiency, inability to demulsify vaccines, etc., and achieve the effect of improving demulsification efficiency and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

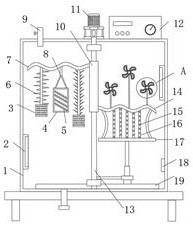

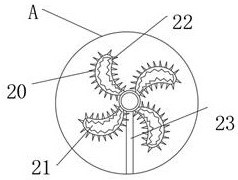

[0030] refer to Figure 1-4 , a demulsification and separation device for vaccine processing, comprising a demulsification and separation box 1, the top outer wall of the demulsification and separation box 1 is fixed with a motor 11 by screws, and the output shaft of the motor 11 is connected with a rotating rod 13 through a coupling. The bottom inner wall of the milk separation box 1 is fixed with a slide rail 19 by screws, and the inner wall of the slide rail 19 is slidably connected with a hydraulic rod 24 through a slider. The top outer wall of the hydraulic rod 24 is fixed with a cross bar 17 by screws, and the Both sides of the top outer wall are welded with arc rods 26, the outer wall of the rotating rod 13 is slidably connected with a sliding sleeve 10, and the top and bottom of both sides of the outer wall of the sliding sleeve 10 are respectively welded with a first wave rod 7 and a second wave rod 14. , both sides of the bottom outer wall of the second wave rod 14 a...

Embodiment 2

[0038] refer to Figure 5 , a demulsification and separation device for vaccine processing. Compared with Embodiment 1, this embodiment also includes a pressure gauge 29 fixed to the outer wall of the top of the demulsification and separation box 1 by screws. A pressure relief pipe 30 is connected, and an outer wall of one side of the pressure relief pipe 30 is connected with a pressure relief valve through a thread.

[0039] Connect the equipment to the power supply, add the vaccine and demulsifier into the demulsification separation box 1 through the feeding pipe 9, turn on the motor 11, the motor 11 drives the rotating rod 13 to rotate, and then the fixed rod drives the hydraulic rod 24 inside the slide rail 19 Rotate, connect the hydraulic rod 24 to the hydraulic system, and adjust the length of the hydraulic rod 24 to make the sliding sleeve 10 slide up and down on the outer wall of the rotating rod 13, and then the first wave rod 7 and the second wave rod 14 are rotated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com