Tool for aligning and assembling balance shaft

A technology of balance shaft and tooling, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., to achieve the effect of saving operating hours, firm clamping and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

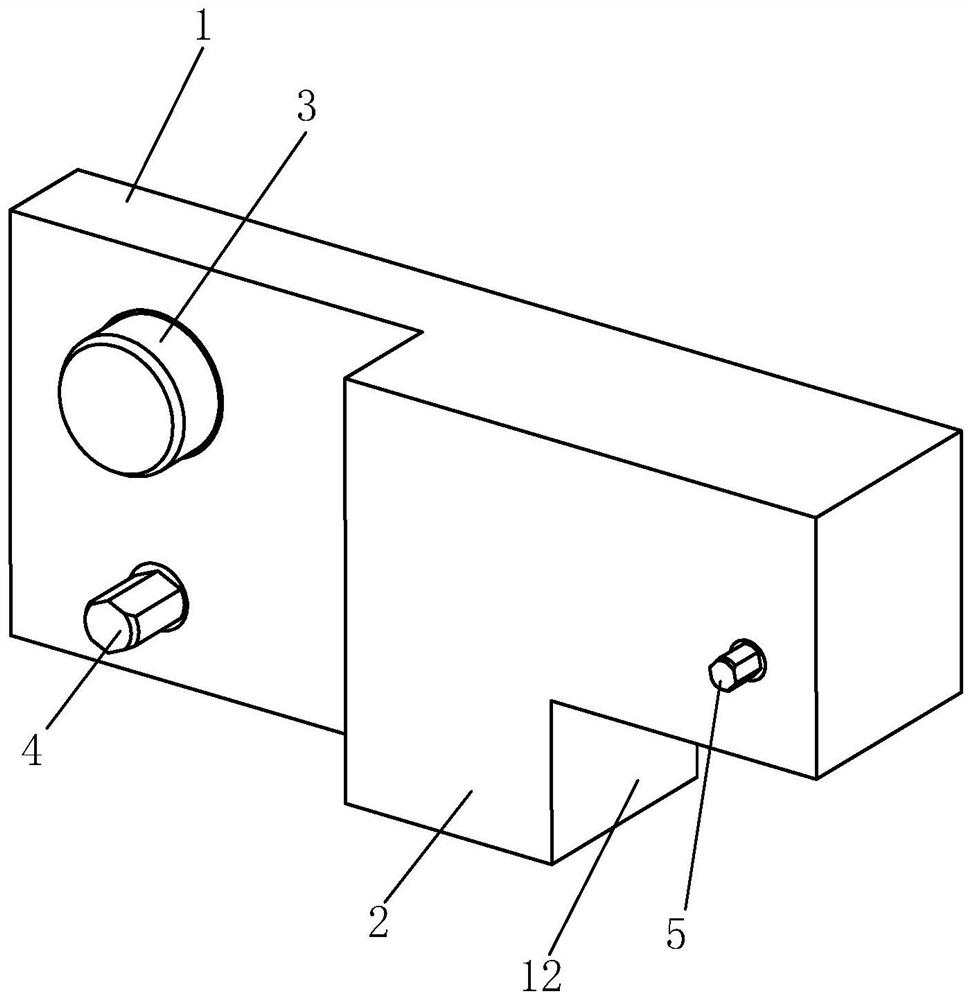

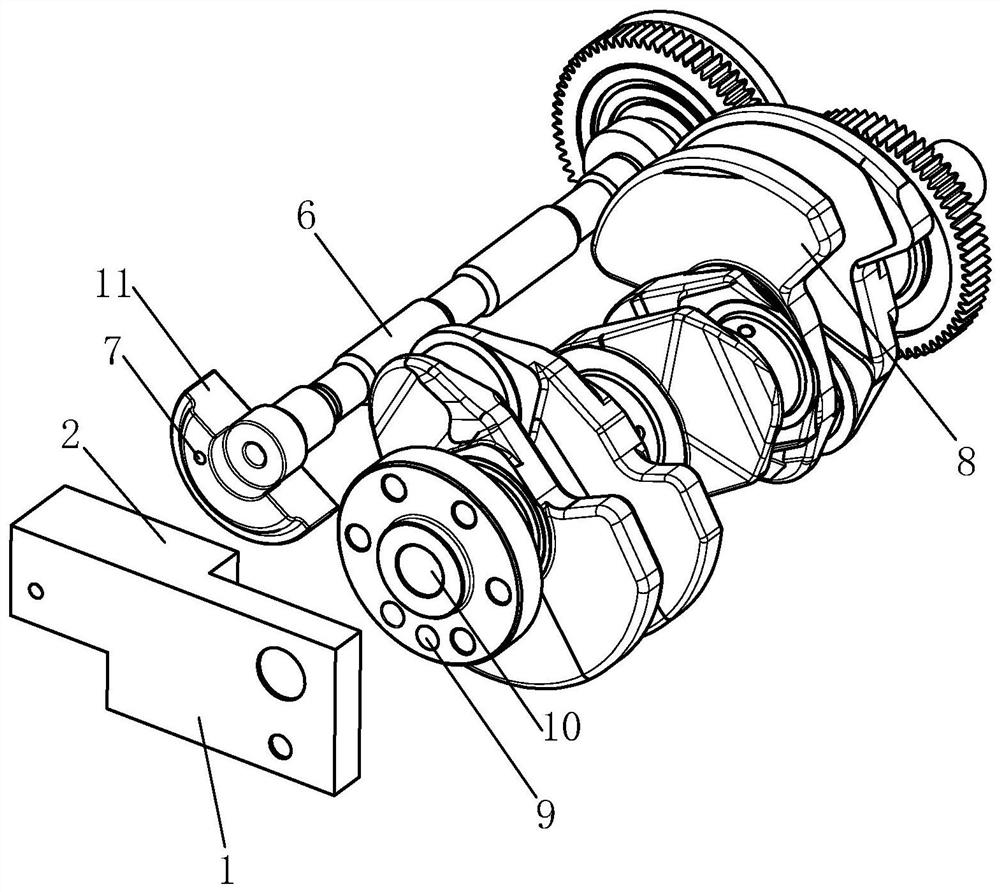

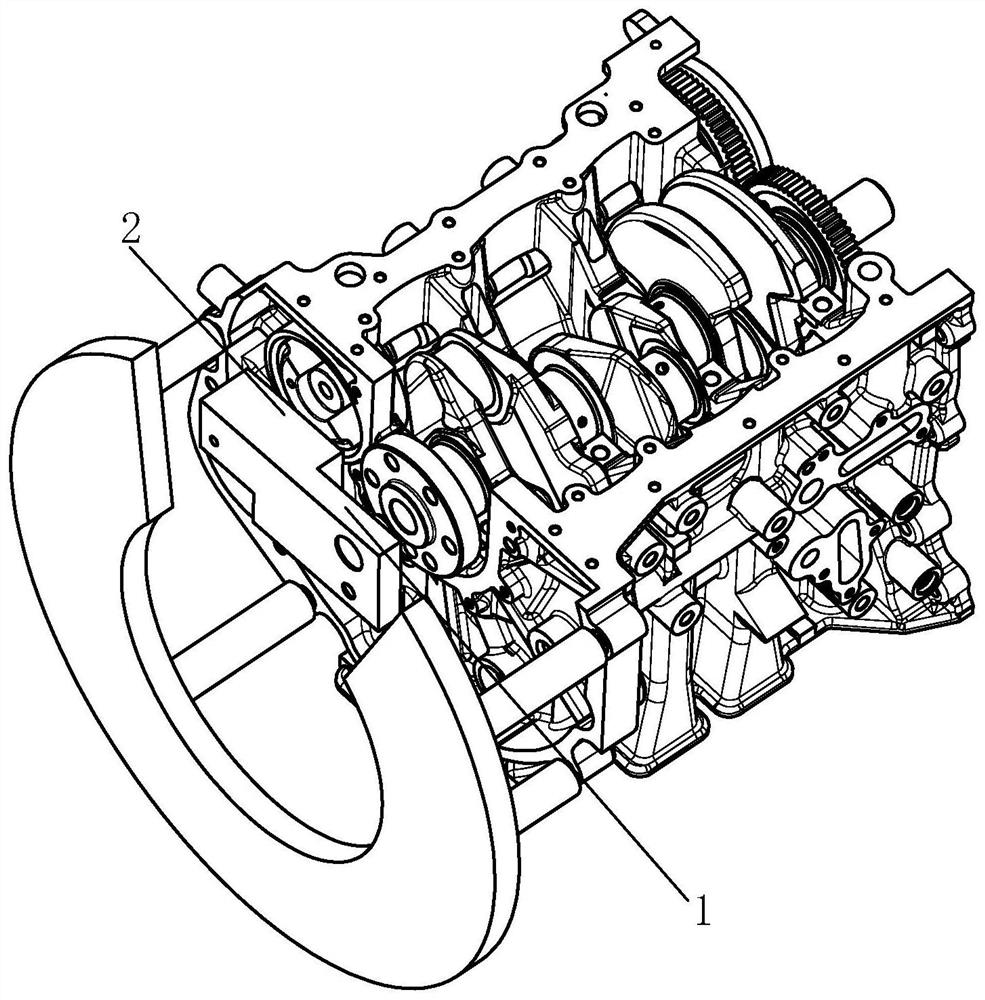

[0015] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, the present invention discloses a tooling for aligning and assembling a balance shaft, including a base block 1, a leveling bump 2, a crankshaft center pin 3, a crankshaft side pin 4 and a balance shaft pin 5, and the base block 1 is installed One end facing the balance shaft 6 is provided with a leveling bump 2, the leveling bump 2 is integrally cast with the base block 1, and the integrally cast base block 1 and the leveling bump 2 cooperate with the end surface of the crankshaft 8 and the balance shaft 6. For the height difference generated by the end faces, when in use, the installation end face of the leveling bump 2 is matched with the rear end face of the balance shaft quality block 11 of the balance shaft 6, and the installation end face of the base block 1 is matched with the rear end face of the rear flange of the crankshaft 8; The outer end of the leveling bump 2 is provided with a gap 12 tha...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment is a further description of Embodiment 1. The mounting surface of the leveling bump 2 is provided with a balance shaft pin installation hole, and the balance shaft pin 5 is embedded in the balance shaft with an interference fit. In the shaft pin installation hole; the installation surface of the base block 1 is provided with a crankshaft center pin installation hole and a crankshaft side pin installation hole, and the crankshaft center pin 3 is embedded in the crankshaft center pin installation hole with an interference fit. The crankshaft side pin 4 is interference fitted and embedded in the crankshaft side pin installation hole.

specific Embodiment approach 3

[0017] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of specific embodiment 1 or 2. The outer ends of the crankshaft center pin 3 , crankshaft side pin 4 and balance pin 5 are all provided with chamfers to avoid damage to the parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com